●

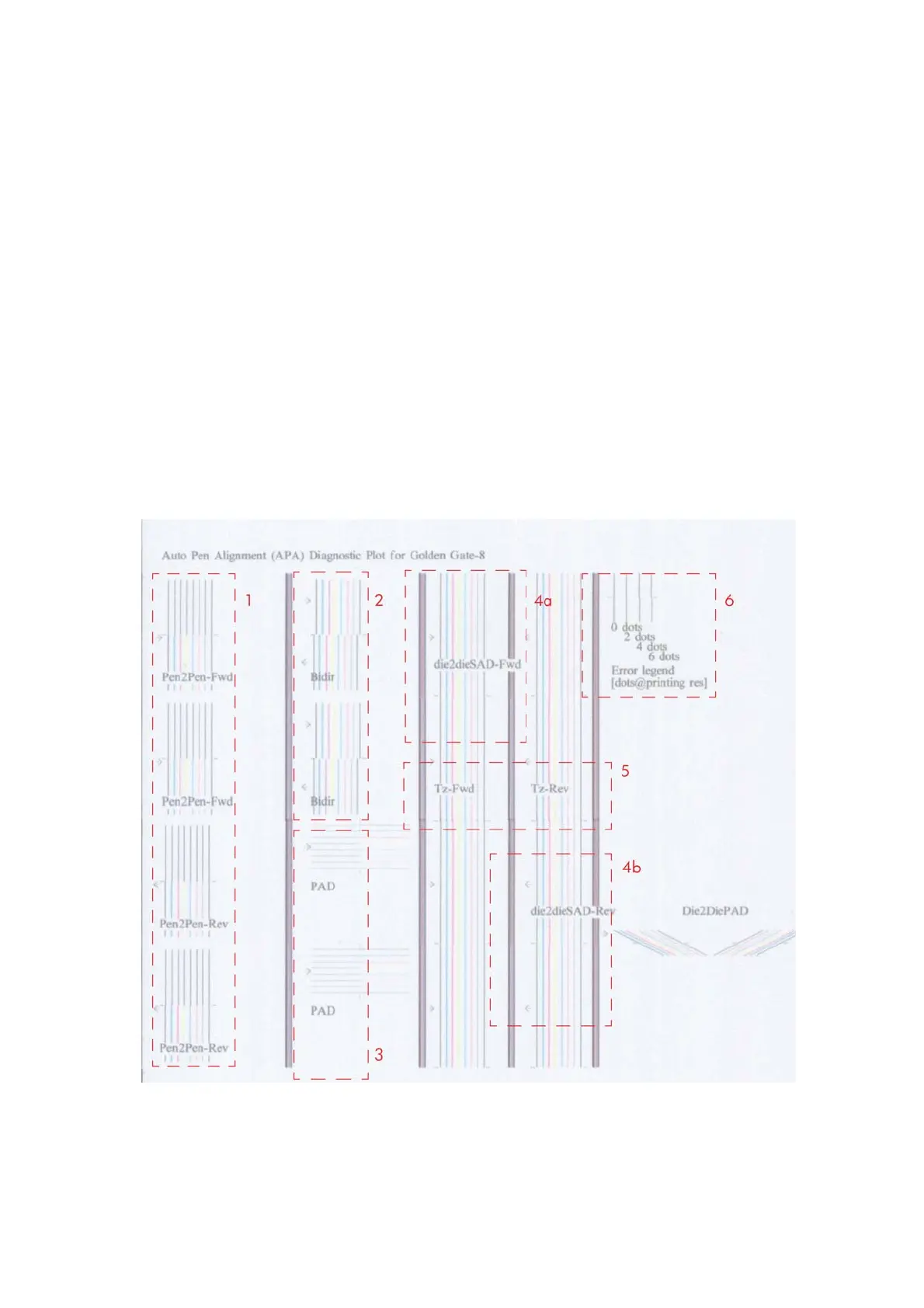

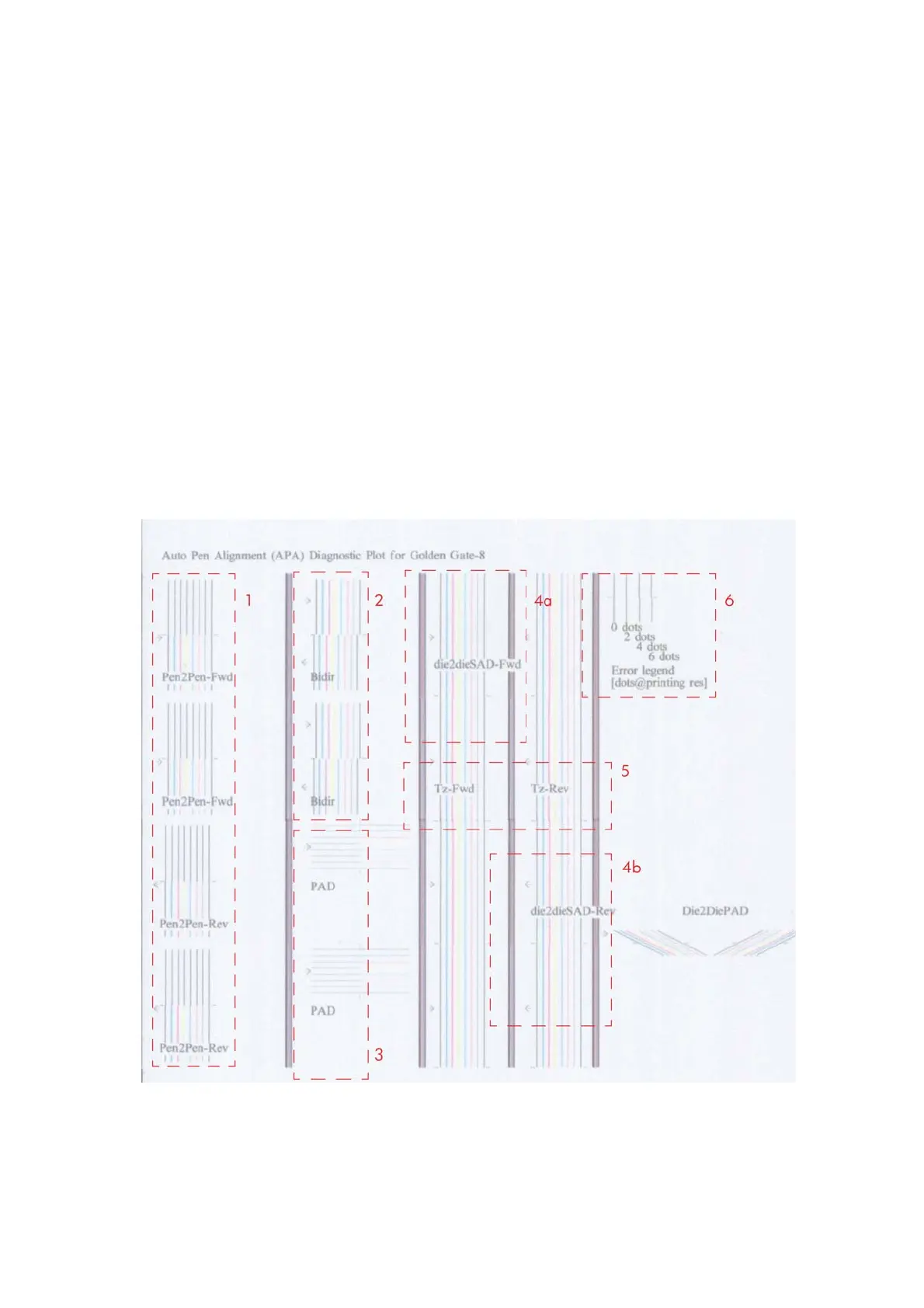

The top pattern is related to the front printhead (nearest to the user when doing the printhead

replacement).

●

The bottom pattern is related to the rear printhead (more far to the user when doing the printhead

replacement)

The area to check is the junction (marked with a “-”) of the black with the rest of colors.

4. The alignment in scan axis direction between both printhead of the same color is marked as 4a (in

forward direction die2dieSAD-Fwd) and 4b (in reverser direction die2dieSAD-Rev).

The area to check is the junction (marked with a “-”). The lines have to be continuous.

5. The ThetaZ of the printhead are checked in the area marked as 5. It checks in forward (Tz-Fwd) and

reverse directions (Tz-Rev).

The area to check is the junction (marked with a “-”). The lines have to be continuous.

6. The area marked as number 6 is a reference legend that shows junction misalignments of 2, 4 and 6

dots. The junction to check has to be below 4 in all cases. If the error is above 4 dots, then realign the

printheads.

In the next example, the Bidir is above this 4 dots and the unit should be realigned. The rest of the pattern

shows a right alignment.

What to see in the Dye Overlap Alignment.

The area to check is only the bottom junction pattern for all the colors. The clearest band has to be around

the 0 (±3 dots). Every band is equal to 1 dot error.

150 Chapter 7 Print quality ENWW

Loading...

Loading...