4. Inspect the drive to decide which of the following conditions most closely matches the symptom on

the drive:

v Tape spooled off the supply reel - All the tape appears to be on the take up reel and no tape is on

the supply reel (inside the cartridge). Test the drive after the procedure is completed.

v Tape pulled from leader pin (or broken at the front end) - All the tape appears to be on the

supply reel (inside the cartridge) and little or no tape appears to be on the take up reel. The leader

block is positioned in the take up reel. Return the drive after the procedure is completed.

v Tape broken in mid-tape - Tape appears to be on both the supply reel (inside the cartridge) and

take up reel. Test the drive after the procedure is completed.

v Tape tangled along tape path - Tape appears to be tangled and damaged but intact. Return the

drive after the procedure is completed.

-- OR --

No damage to tape (or no apparent failure) - There appears to be no damage or slack to the tape.

Return the drive after the procedure is completed.

Full height drive: Tape spooled off supply reel

About this task

Note: If the cartridge in the drive is an INPUT tape that contains ACTIVE or 'ONLY COPY' data (there is

no backup), eject commands that are issued at the host fail to unload the tape, and power-cycling the

drive fails to eject the cartridge, make no further attempts to unload this tape. Call Technical Support

and open a PMR if one is not already open, to initiate the process of sending the drive with the loaded

cartridge in for recovery.

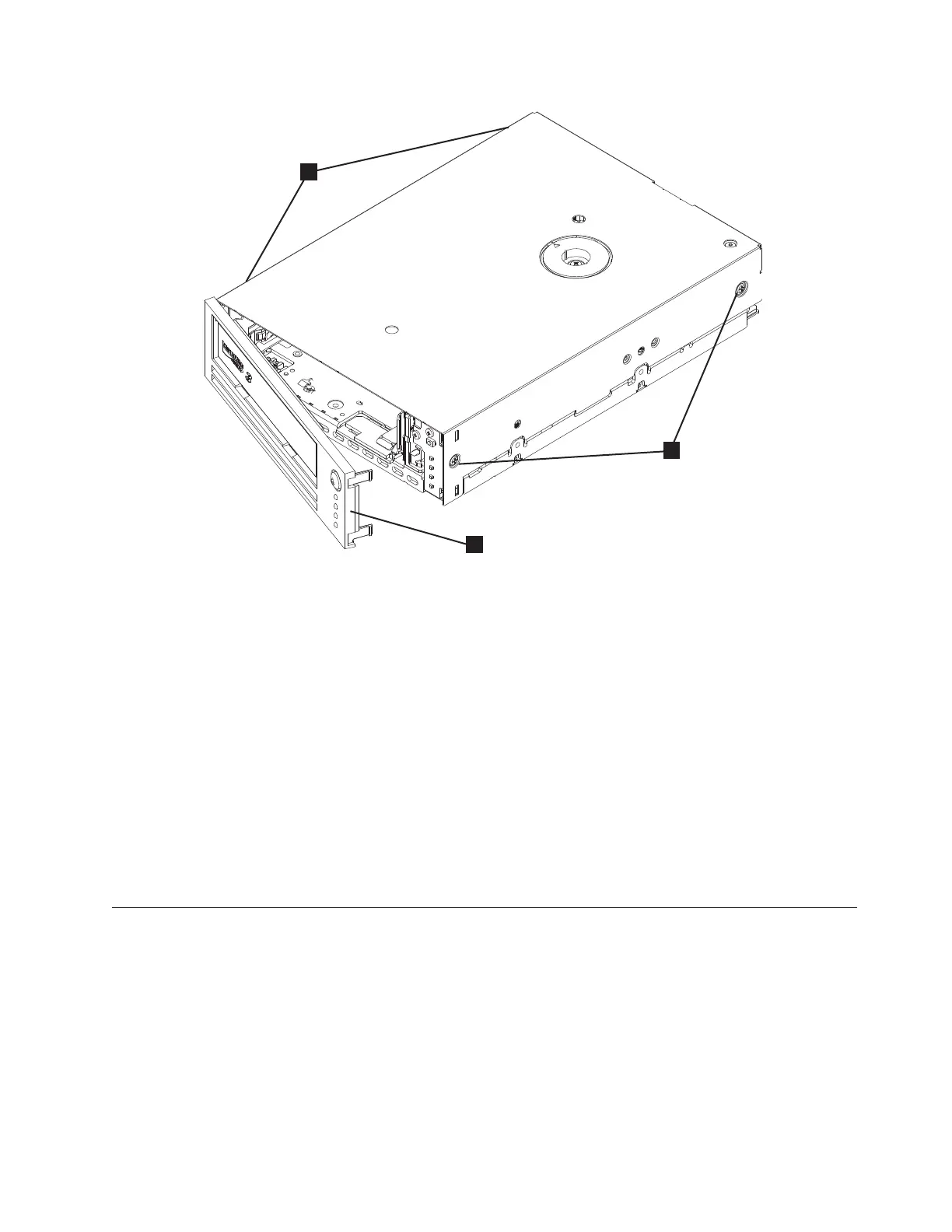

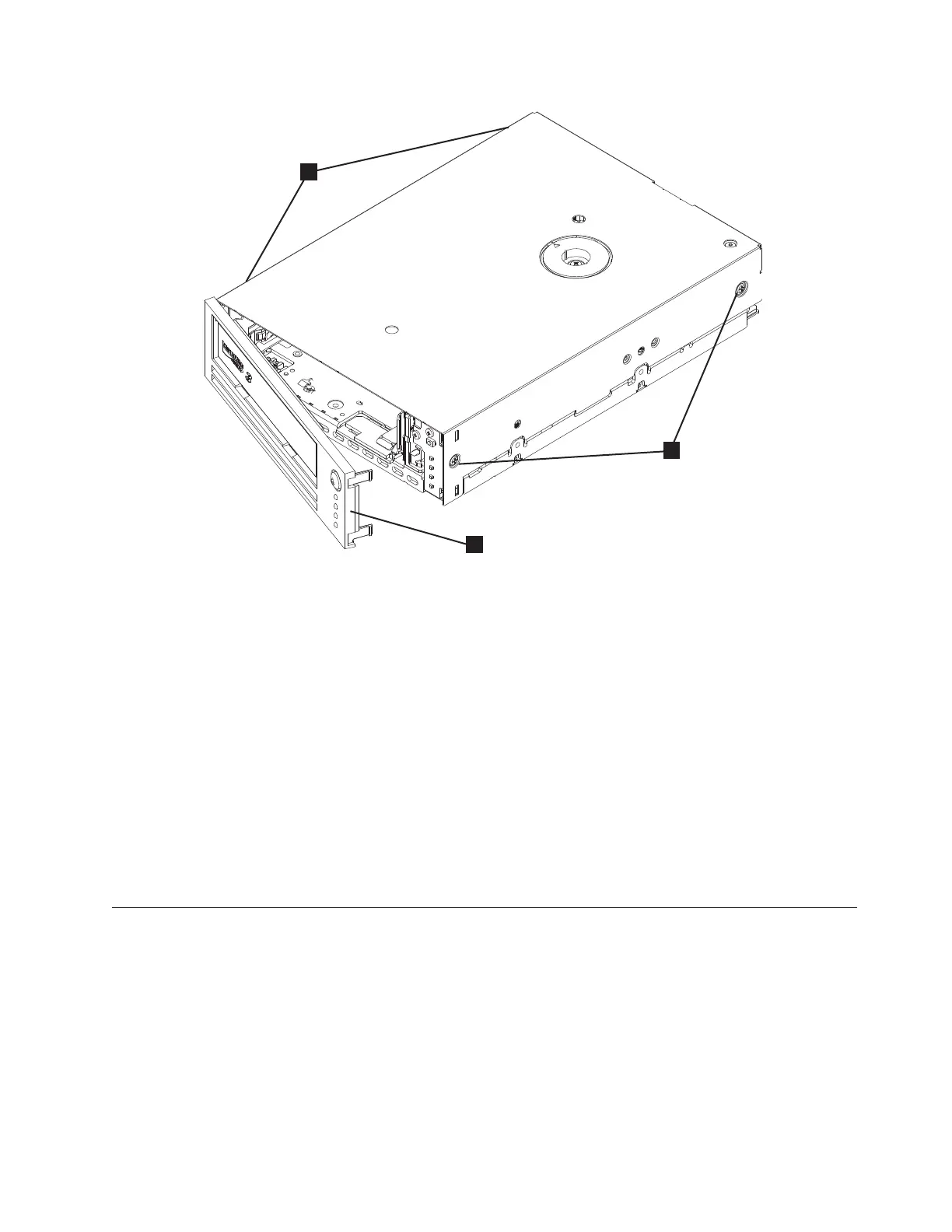

Figure 199. Removing the bezel and the cover from the half height internal drive

Appendix A. Information for trained service personnel 265

Loading...

Loading...