7. Turn the supply reel clockwise, carefully guiding the mended portion of the tape to wind around the

hub of the supply reel that is located inside the cartridge. Continue spooling into the cartridge until

the tape is taut. The tape must remain within the flanges of the tape guiding rollers. Ensure that you

do not stretch the tape.

8. Go to “Ending procedure” on page 283.

Half height drive: Tape broken in mid-tape

Procedure

1. With the front of the drive facing you, pull an arm's length of tape out of the takeup reel. From the

takeup reel, thread tape around the rear of the tape path and over the head rollers on the left side of

the drive.

Note: If there is less than approximately 5 cm (2 in.) of tape on the takeup reel, go to “Half height

drive: Tape pulled from or broken near leader pin” on page 270.

2. From the supply reel inside the cartridge, pull approximately 0.3 m (1 ft.) of tape.

3. Ensure that the tape is not twisted. Untwist the tape if required

4. Moisten a cotton swab with water, and wet approximately 13 mm (0.5 in.) of the tape end. Overlap

the tape ends, loosely mending them together.

5. Set the drive on its left side with the head and tape path facing up

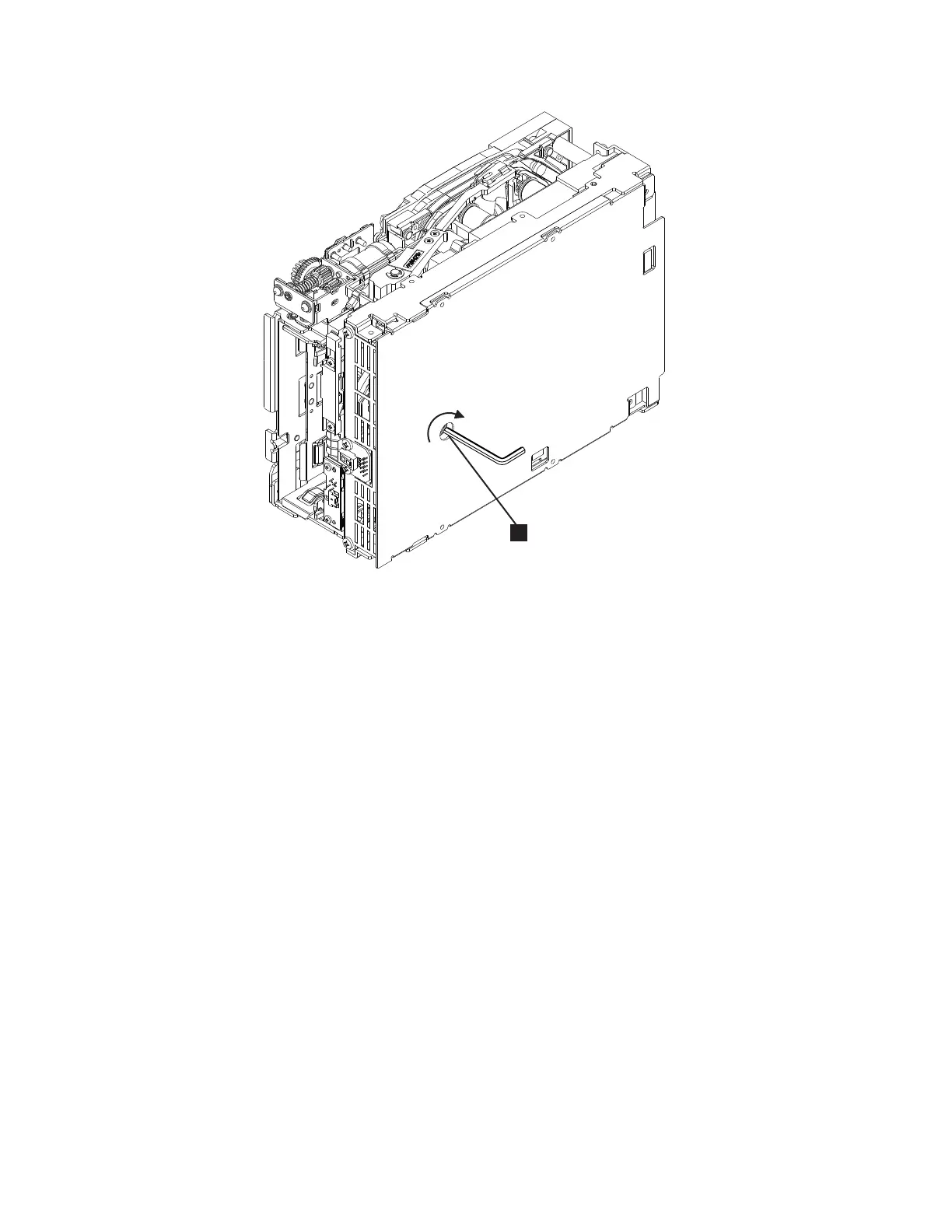

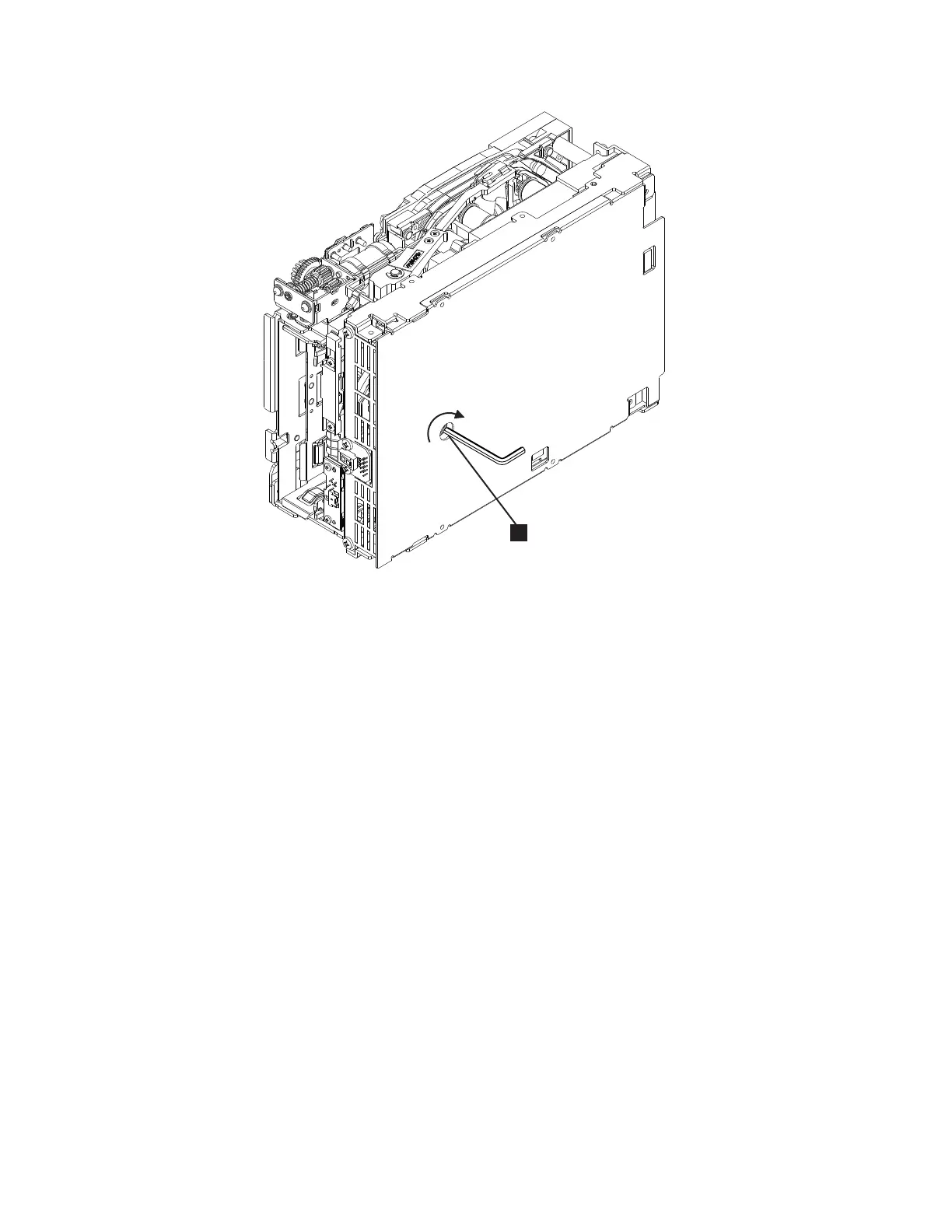

6. Turn the supply reel (▌4▐) clockwise, carefully guiding the mended portion of the tape to wind

around the hub of the supply reel that is located inside the cartridge. Continue spooling into the

cartridge until the tape is taut. The tape must remain within the flanges of the tape guiding rollers.

Turn the supply reel (▌4▐) 10 more turns. Ensure that you do not stretch the tape.

Figure 206. The hex wrench rewinds tape into cartridge

272 IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Loading...

Loading...