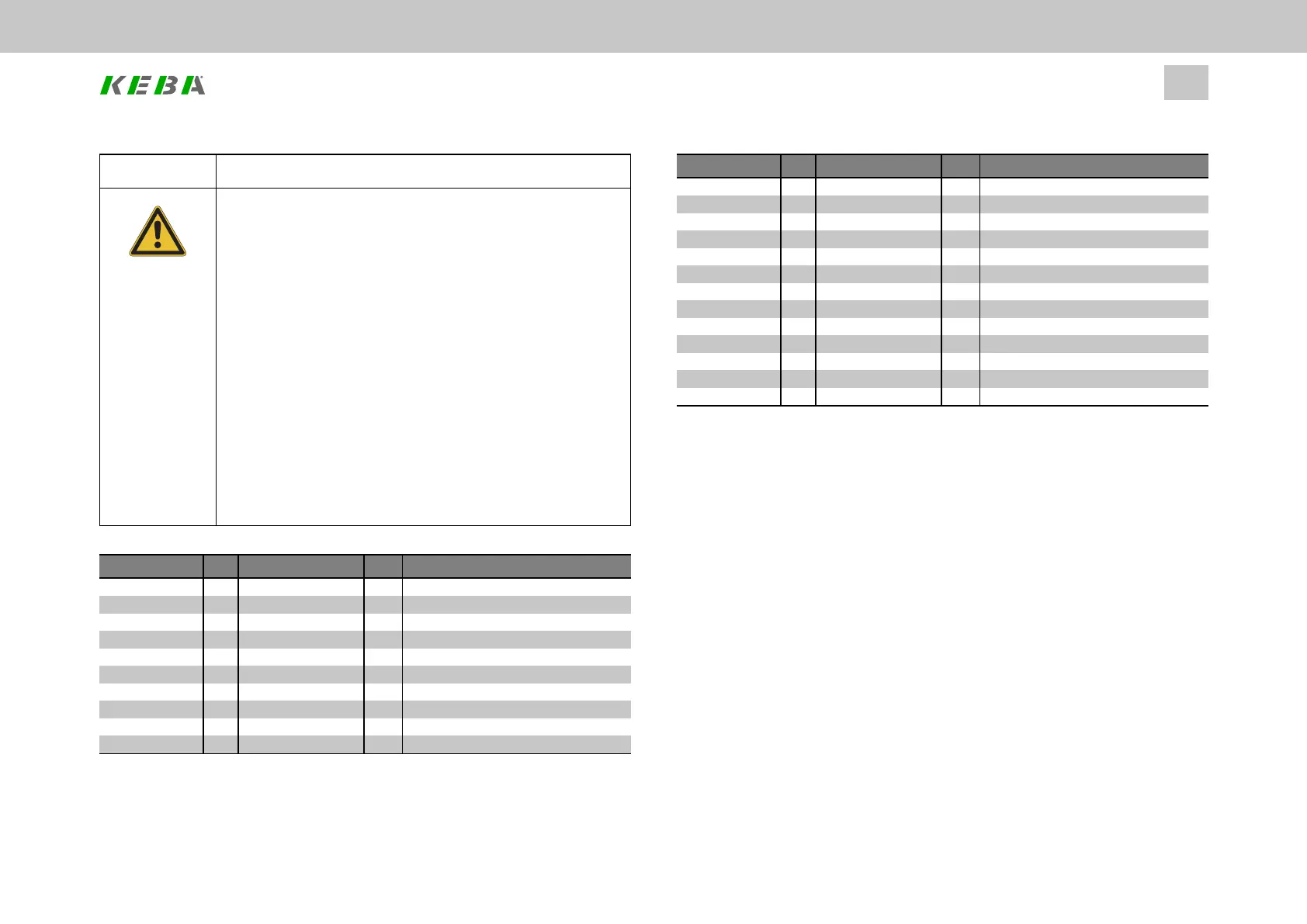

CAUTION! Damage to the device as a result of incorrect operation!

Failure to exercise caution or follow proper working

procedures may result in damage to the device.

l Themotorcanmovesuddenlyduringtheauto

commutation.Themechanismcoupledmustbe

designedforthismovement.

l Ifthecommutationpositionisnotdeterminedcorrectly,

themotorwillaccelerateinanuncontrolledmanner,

Thiscanleadtodamagetothemechanicalsystem.

l Makesuretocarefullytesttheautocommutation

function.Varythestartposition.Evenif

autocommutationhasnotbeenperformed,thedrivecan

be“madetorotate”inupto50%ofcases.

l Enablespeedtrackingerrormonitoring(P 744[0] -

SDiffMax,Section"Speed-/velocitylimits"onpage

326).Thismonitoringfunctionprovidesextensive

protectionagainstuncontrolledmovement.

ID Index Name / Setting Unit Description

365 0 CON_ICOM_AutoOn autorecommutationafterselectedevent

366 0 CON_ICOM_RefSpeed rpm commutationdetection:scalingofcontrolgain

390 0 CON_ICOM Autocommutation:Controlwordforselection

Off(0) Functiondisabled

IENCC(1) Currentinjection

LHMES(2) Saturationofinductanceevaluated

IECSC (3) Not yet implemented

IECON(4) Currentinjection,minimizedmovement

HALLS (5) Not yet implemented

HALLSDIGITAL(6) DigitalHallsensor

Table 7.36: “Auto commutation” parameters

ID No.: 0842.26B.5-01Date: 09.2020

ServoOne- Device Help

159

7 Control

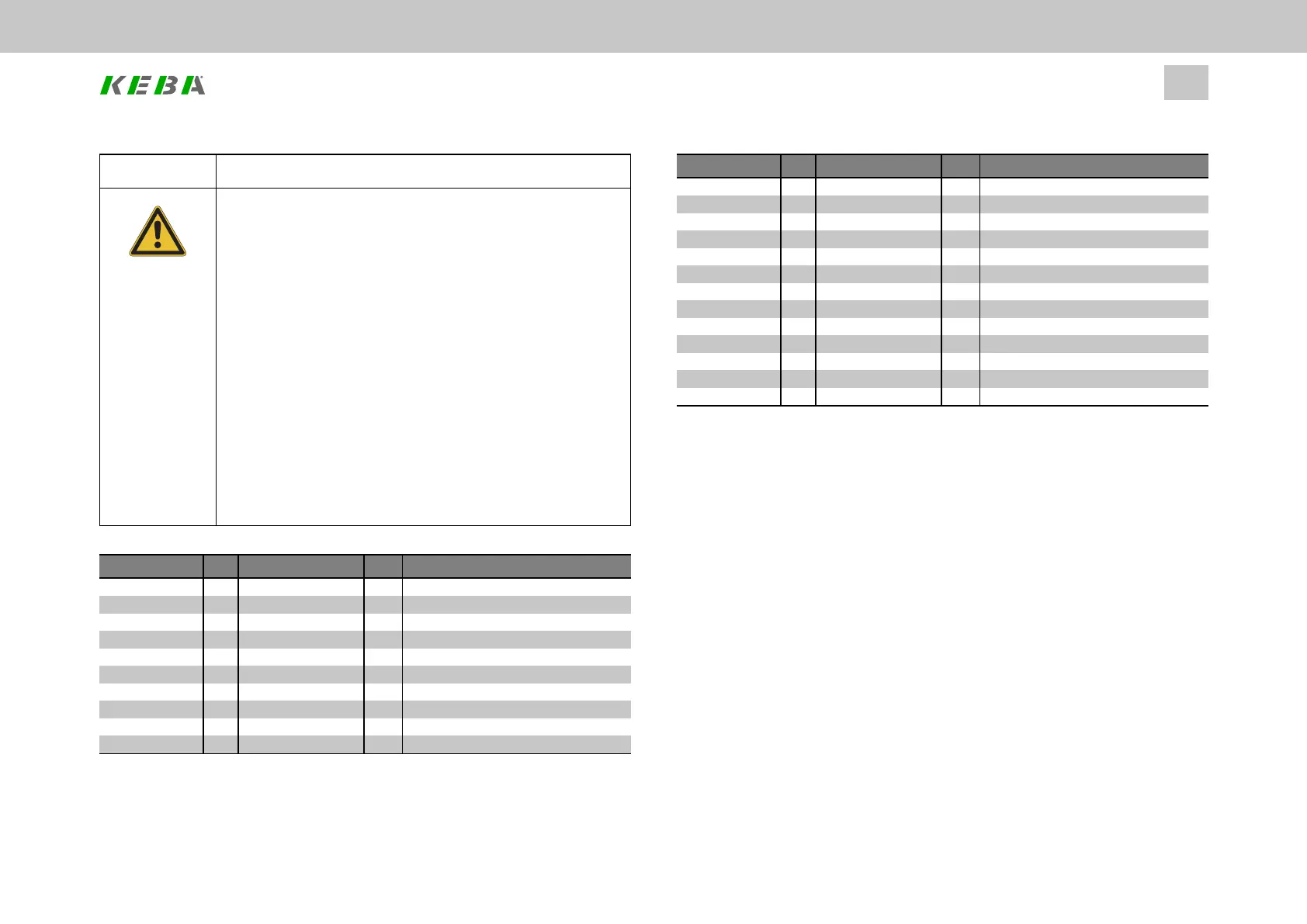

ID Index Name / Setting Unit Description

HALLSDIGITAL2(7) DigitalHallsensor(alternateprocess)

391 0 CON_ICOM_KpScale % commutationdetection:scalingofcontrolgain

392 CON_ICOM_Time commutationdetection:times

392 0 CON_ICOM_Time ms

392 1 CON_ICOM_Time ms

392 2 CON_ICOM_Time ms

392 3 CON_ICOM_Time ms

393 CON_ICOM_Current commutationdetection:currents

393 0 CON_ICOM_Current A

393 1 CON_ICOM_Current A

394 CON_ICOM_Check Monitoringautocommutation

394 0 LIMIT degree Autocommutation:Angleerrorlimit

394 1 ActVal degree Autocommutation:Angleerroractualvalue

Table 7.36: “Auto commutation” parameters (continue)

Loading...

Loading...