5.3Linearsynchronousmotor

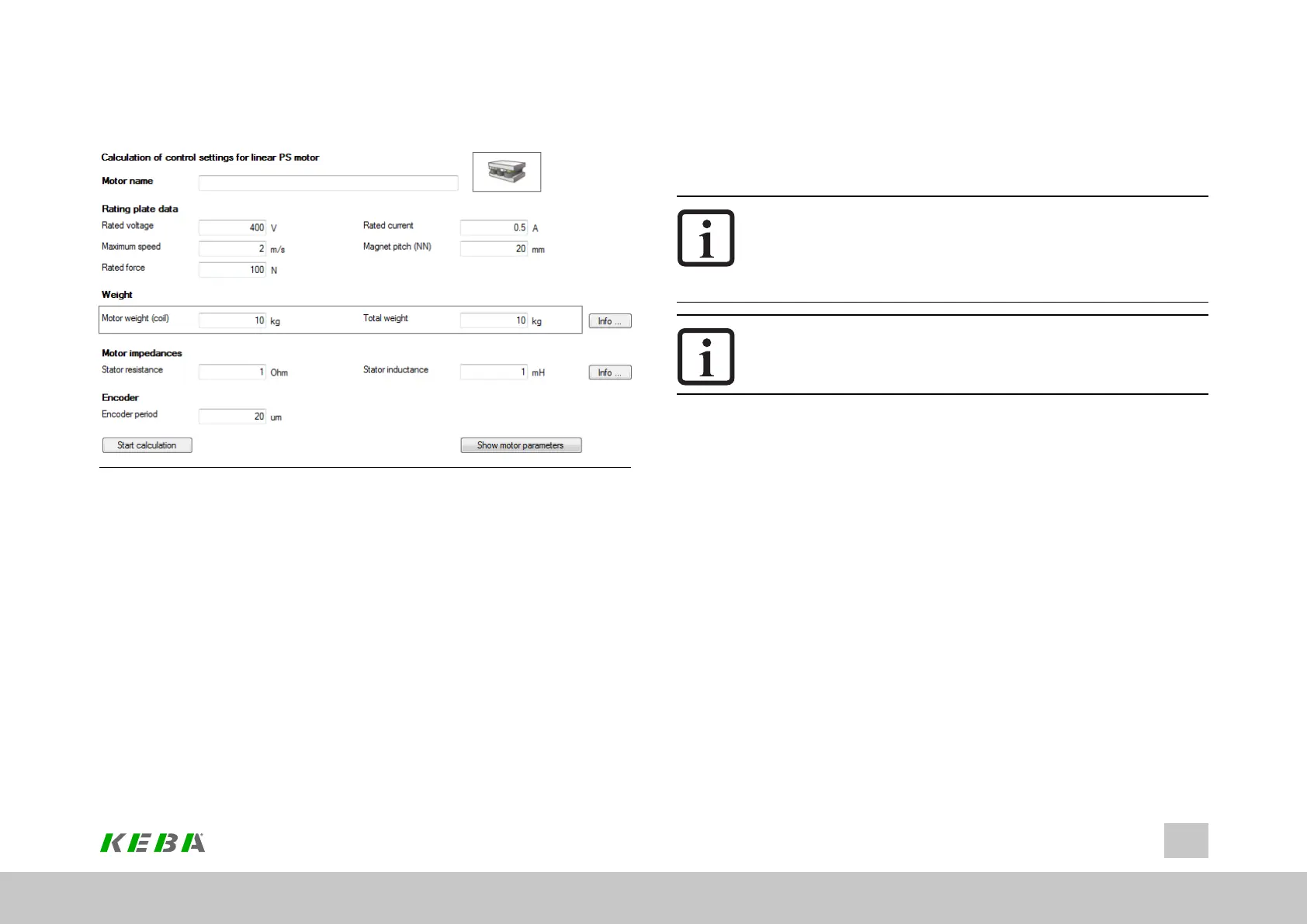

Image 5.4: “Linear synchronous motor settings” screen

There are two methods of creating a motor data set for the linear synchronous motor.

l Variant1:Motorcalculation

l Variant2:Motoridentification(seeSection"Motoridentification"onpage45)

Variant 1: Motor calculation

l Enterthemotordata

Themotordatarelevanttothecalculationmustbeenteredfromthedata

sheet.

l Clickon“Startcalculation”.

l IfthemomentofinertiaofthemotorP 461 - Mot_Jisnotknown,avalue

roughlycorrespondingtothemotor'smomentofinertiamustbeapplied.

ID No.: 0842.26B.5-01Date: 09.2020

ServoOne- Device Help

36

5 Motor

l ThecalculationprocesscanbemonitoredintheKeStudioDriveManager5

viathemenu,View,Messages.

l Calculationofoperatingpoint:FluxP 462 - MOT_FLUXNom

l Calculationof:current,speedandpositioncontrolparameters

NOTE

l P 490 - MOT_ISLinRot =LIN(1):Theparameterautomaticallysets

thenumberofpolepairsforthemotortoP 463 - Mot_PolePairs =

1.Asaresult,aNorthtoNorthpolepitchcorrespondstoone

virtualrevolution(P 492 - Mot_MagnetPitch).

NOTE

l Allexistingmotorparametersareoverwritten.

Calculated values

l Translationofthelinearnominalquantitiesintovirtualrotarynominal

quantities

l Defaultvaluesforautocommutation

l Encoderlinespervirtualrevolution

l Fluxsettings(includingfortorqueconstant)

l ControlsettingsforPIcurrentcontroller:thecurrentcontrollerisdimensioned

basedontheactualswitchingfrequencyset.

l PIspeedcontrollerandpositioncontrollergain:Amoderatelyrigid

mechanismandmomentofinertiamatchingfromloadtomotorwitharatioof

1:1isassumedhere.

l Thedefaultvalueforspeedtrackingerrormonitoringcorrespondsto50%of

thenominalspeed.

l V/Fcharacteristic

Loading...

Loading...