ID Index Name / Setting Unit Description

7 ENCPOS_CH3(7)=Encoderposition

Channel3

8 ENCPOS_CH3_INC(8)=Encoderposition

Channel3inincrements

9 ENCPOS_CH4(9)=Encoderposition

Channel4

10 ENCPOS_CH4_INC(10)=Encoder

positionChannel4inincrements

11 ACTPOS2(11)=Actualpositionof

redundantencoderinuserunits

12 Sercos(12)=ReferredtoSercosprofile

parametersS-x-0426,S-x-0427

13 UserRefPos(13)=Referencepositionin

userunits

14 MasterPosST(14)=Masterposition

(ECAM,EGEAR)singleturn,alwayssteps

15 CommonMasterPos(15)=Masterposition

(ECAM,EGEAR)singleturn,alwayssteps

16 CommonMasterPosST(15)=Master

position(ECAM,EGEAR)singleturn,

alwayssteps

1402 0 MPRO_TP_Channel

1402 1 MPRO_TP_Channel

1402 2 MPRO_TP_Channel

1404 MPRO_TP_Lines Touchprobe:Lines@pulsecounteron

channelx

1404 0 MPRO_TP_Lines

1404 1 MPRO_TP_Lines

Table 8.29: “Touch probe” parameters (continue)

NOTE

l Formoreinformationrefertothebussystemusermanualsorthe

descriptionoftheiPLC.

ID No.: 0842.26B.5-01Date: 09.2020

ServoOne- Device Help

279

8 Motion profile

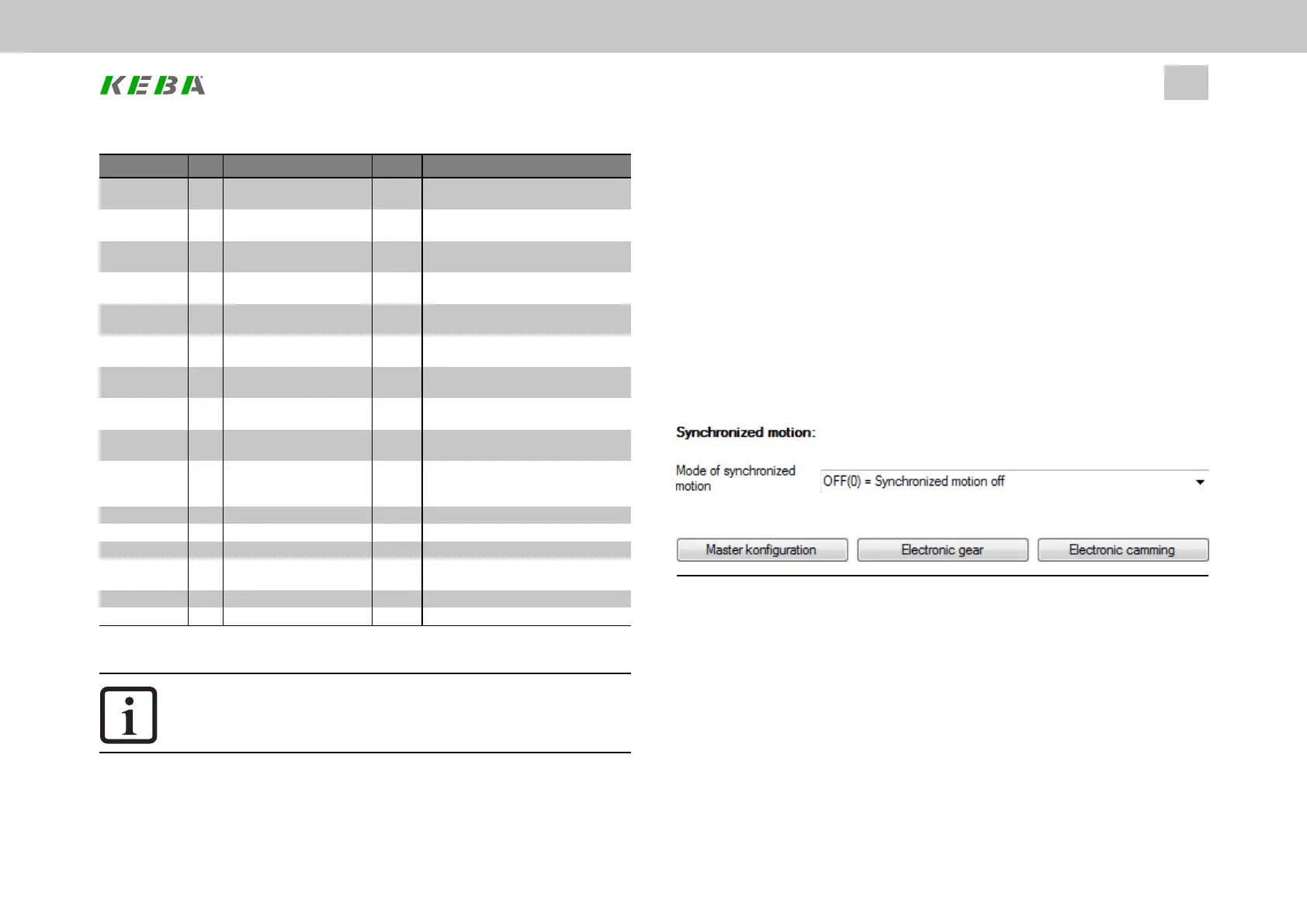

8.11Synchronizedmotion

The Synchronized Movement function enables synchronous running of the drive in

relation to a real or virtual master axis.

Digital control signals are used to provide positionally precise disengagement from

the guide value (e.g. with standstill at cycle end) and positionally precise

engagement to the current guide value.

An encoder system, the virtual master or the parameter interface is selected as the

master encoder in the master configuration. By setting the parameter interface to a

bus system (Basic setting Control and Reference) control is programmed via a bus

system.

Image 8.71: “Synchronized motion” screen

There are various modes available in the “synchronization mode” drop-down menu

(P242[0] - MPRO_ECAM_SyncModMode):

l Off(0)=Synchronizedmotionoff

l ECAM_iPlc(1)=ElectroniccamplateviaiPlc

l EGEAR_iPlc(2)=Electr.gearunitviaiPLC

l ECAM_PARA(3)=Electroniccammingviaparameters

l EGEAR_PARA(4)=Electronicgearingviaparameters

Loading...

Loading...