CYLINDER HEAD AND VALVE TRAIN 127

Cylinder Head Warpage

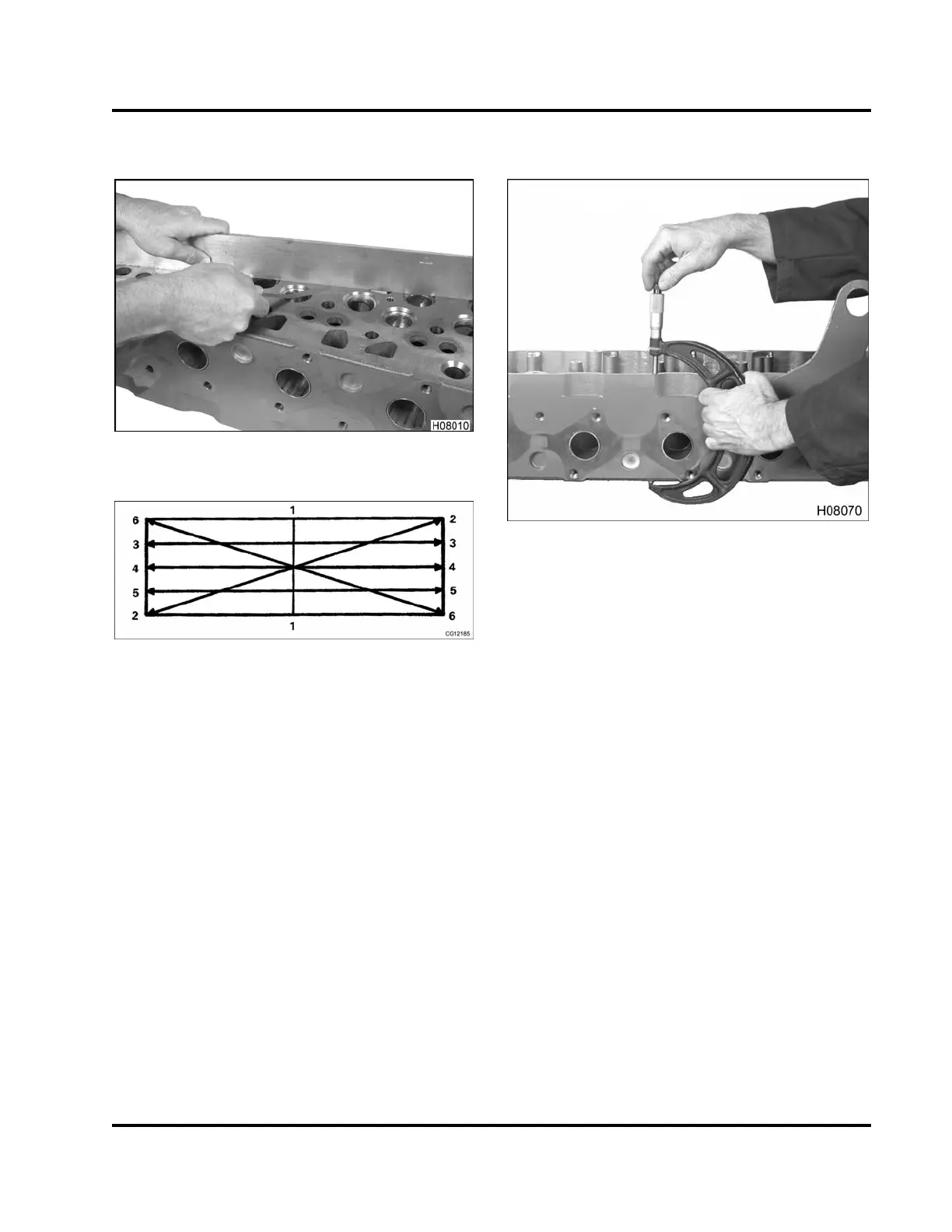

Figure 151 Checking for warpage

Figure 152 Checking pattern

Use a straightedge and feeler gauge to check the

gasket surface of the cylinder head for warpage.

Use the checking pattern that is shown. If warpage is

present as indicated by a feeler gauge measurements

exceeding cylinder head gasket surface flatness

specifications, check thickness of cylinder head.

Cylinder Head Thickness

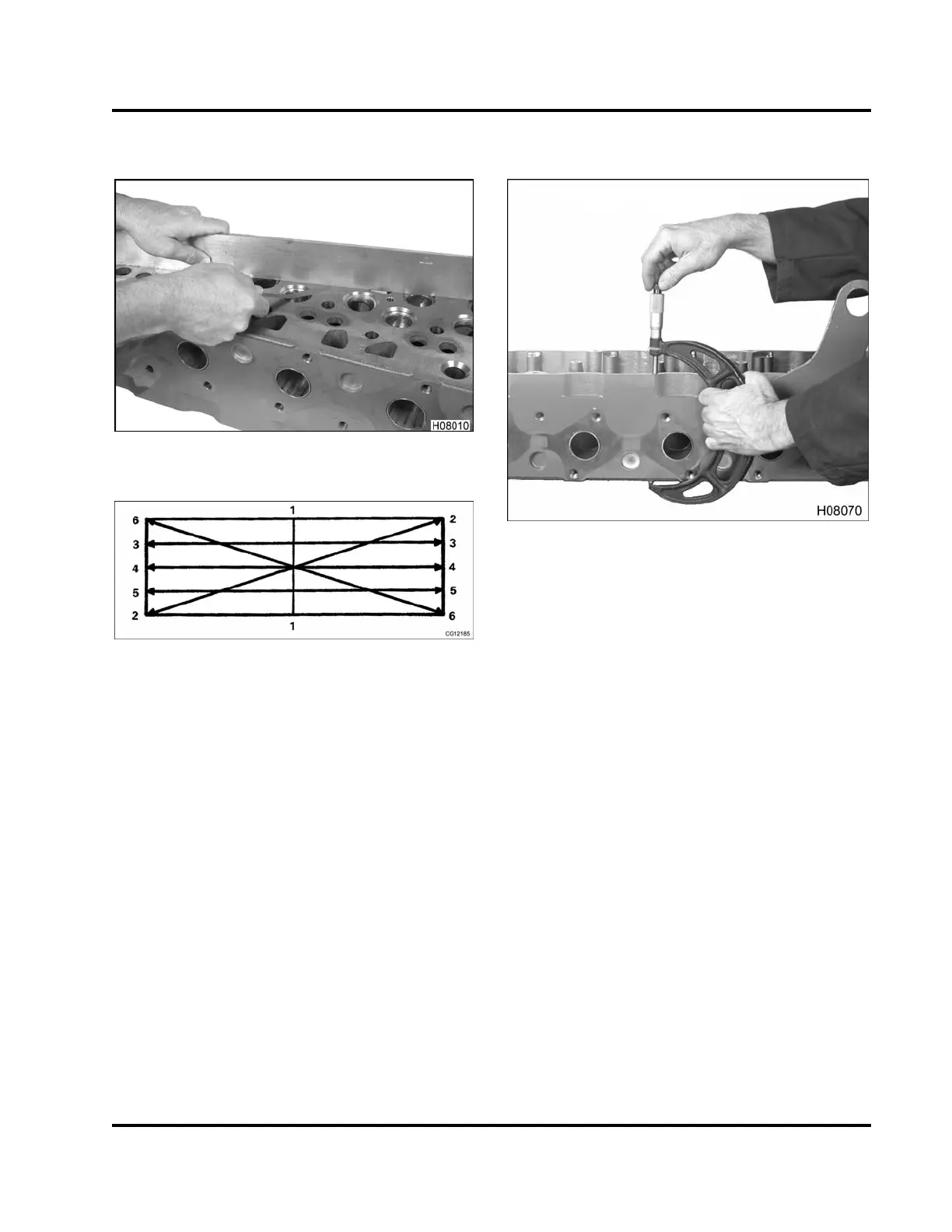

Figure 153 Checking cylinder head thickness

Usea6-7inchoutsidemicrometertomeasure

the thickness of the cylinder head at six locations

(four corners and two center points). Cylinder

head thickness must equal or exceed the minimum

specification after resurfacing. If the minimum

specification after resurfacing cannot be met, replace

cylinder head.

Valve Seat Leakage

NOTE: This test does not check for the condition of

the valve guides or the valve stem-to-valve guide

clearance.

1. Position the cylinder head on wood blocks with the

gasket surface facing down.

2. Squirt mineral spirits into the intake and exhaust

valve ports and wait 5 minutes.

3. Use an inspection mirror to check valve seat area

for leakage of the mineral spirits past the valve

seats.

NOTE: If leakage occurs, the valves must be

reconditioned.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...