138 CYLINDER HEAD AND VALVE TRAIN

Installation

1. Use a micrometer to measure the diameter of the

valve seat insert counterbore at two locations,

90° apart. Average the two measurements to

determine the appropriate size valve seat insert

to install.

Table 12 Valve Seat Insert Selection Chart

Available inserts (int. and

exh.)

Ave. dia. of intake counterbore Ave. dia. of exhaust counterbore

Standard 40.119 - 40.170 mm (1.5795 - 1.5815

in)

37.478 - 37.529 mm (1.4755 - 1.4775

in)

Oversize - 0.05 mm (0.002 in) 40.170 - 40.221 mm (1.5815 - 1.5835

in)

37.529 - 37.579 mm (1.4775 - 1.4795

in)

2. Chill the valve seat insert in a freezer for 30

minutes. This will prevent the outer layer of metal

from being shaved off during installation.

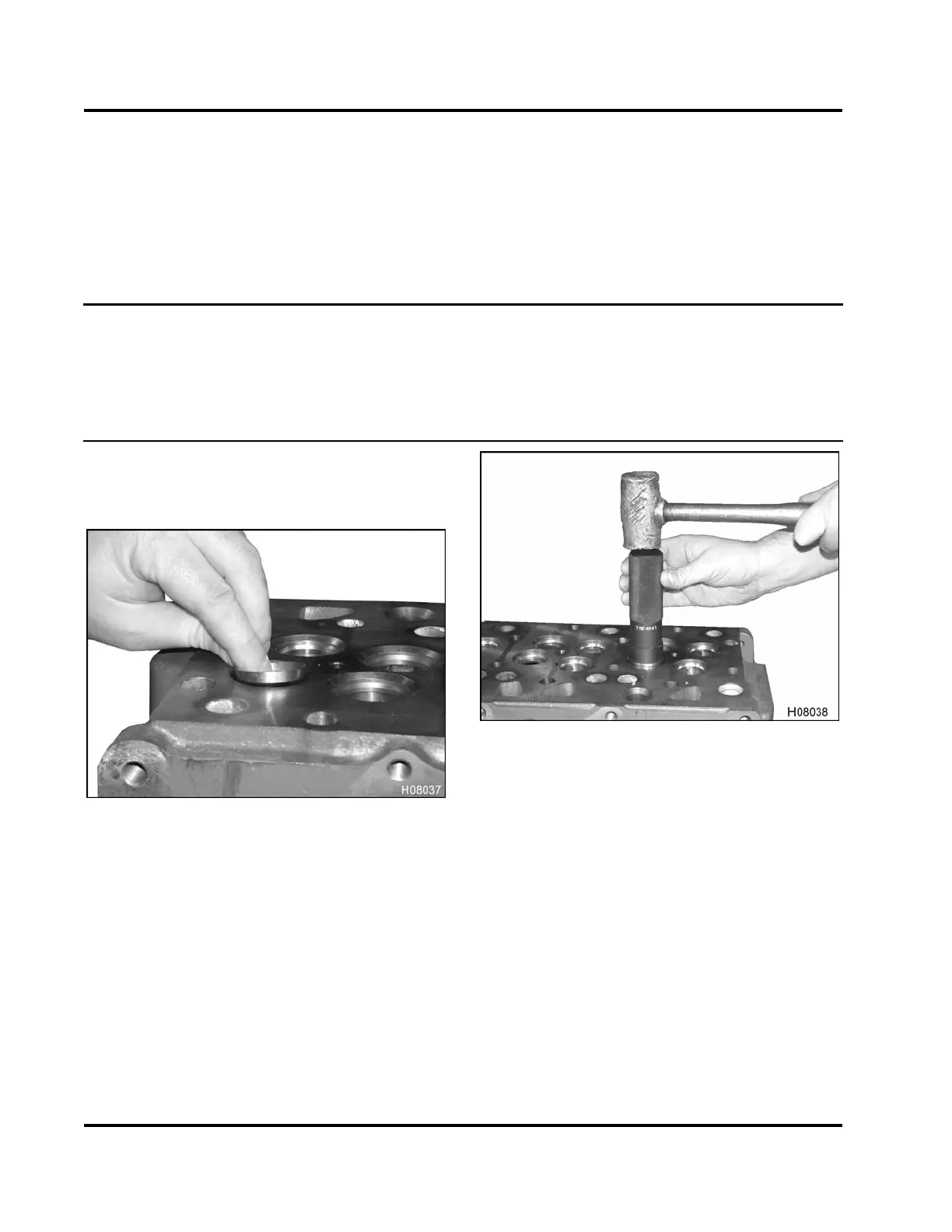

Figure 182 Placing chilled valve seat into head

3. Align insert over counterbore to avoid

misalignment.

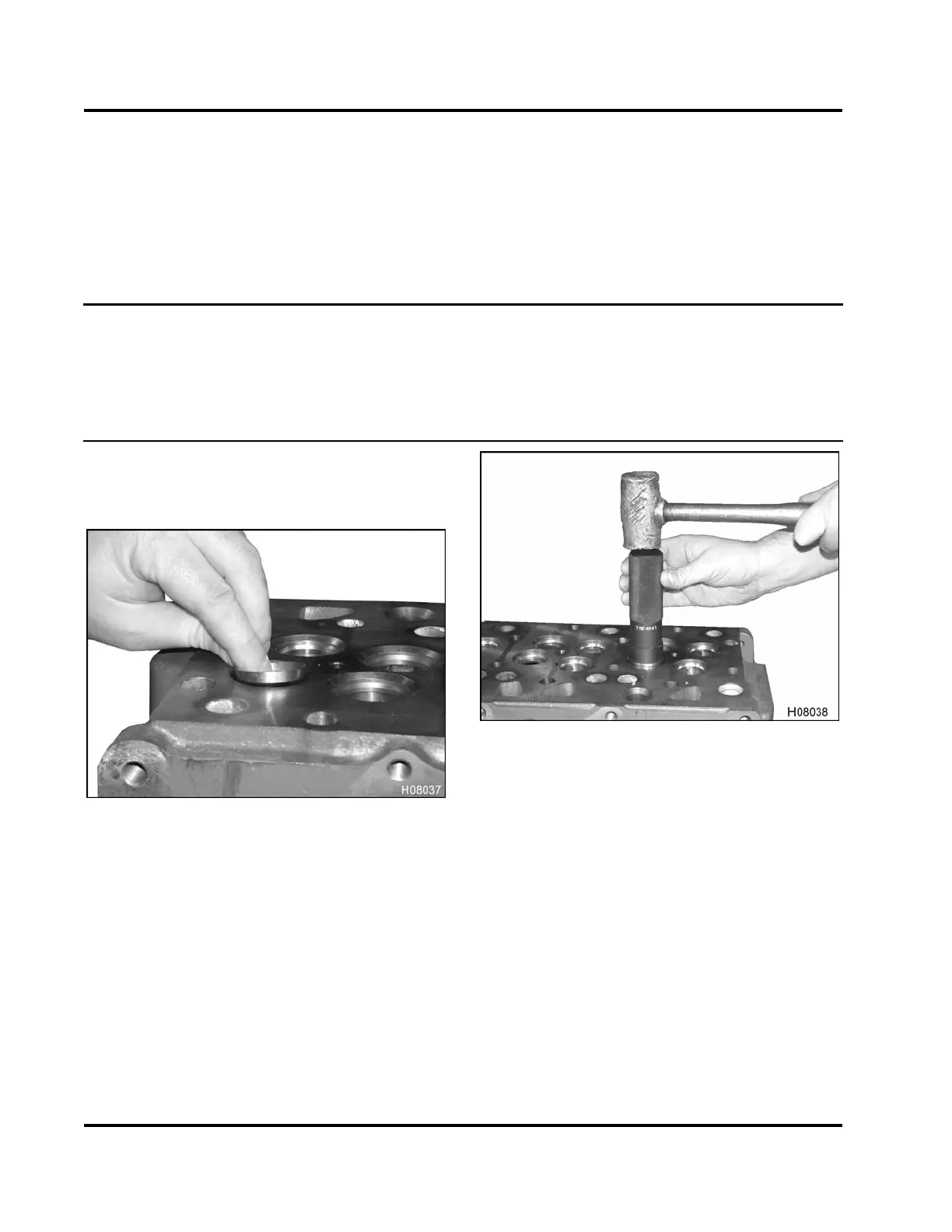

Figure 183 Driving valve seat into place

4. Using a hammer and valve seat installation tool

drive the valve seat into place until it is fully

seated. See Cylinder head and valve special

service tools (Table 17).

5. Grind new valve seats to the specified angles and

widths, see Cylinder Head Specifications (Table

15) in this section.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...