FUEL SYSTEM 357

1

2

3

H11052

Figure 565 IPR orientation

1. Fitting assembly, M18

2. Bolt,M8x100(2)

3. Bolt, M8 x 30 (2)

3. Install two bolts (M8

x 100) behind pump and

two bolts (M8 x 30) ou

tside, securing the

high-pressure pump

to the front cover. Tighten

bolts to the specia

l torque value (Table 47).

High-pressure Hose Assembly – Generation 1

Figure 566 Installation of high-pressure hose

assembly

1. Install a new O-ring seal onto the high-pressure

pump assembly before installing the

high-pressure hose assembly. Tighten swivel nut

by hand.

2. Install a new O-ring seal onto the high-pressure

fitting (M18) at the cylinder head before installing

the high-pressure hose assembly.

3. Orient hose fitting assembly at the cylinder head

at 0°± 7° relative to horizontal. Tighten swivel nut

by hand.

4. Using a crowfoot, tighten both swivel nuts to the

special torque value (Table 47) making sure hose

is not under any excess tension.

High-pressure H ose Assembly with 70 and 90

Degree Elbows – Generation 2

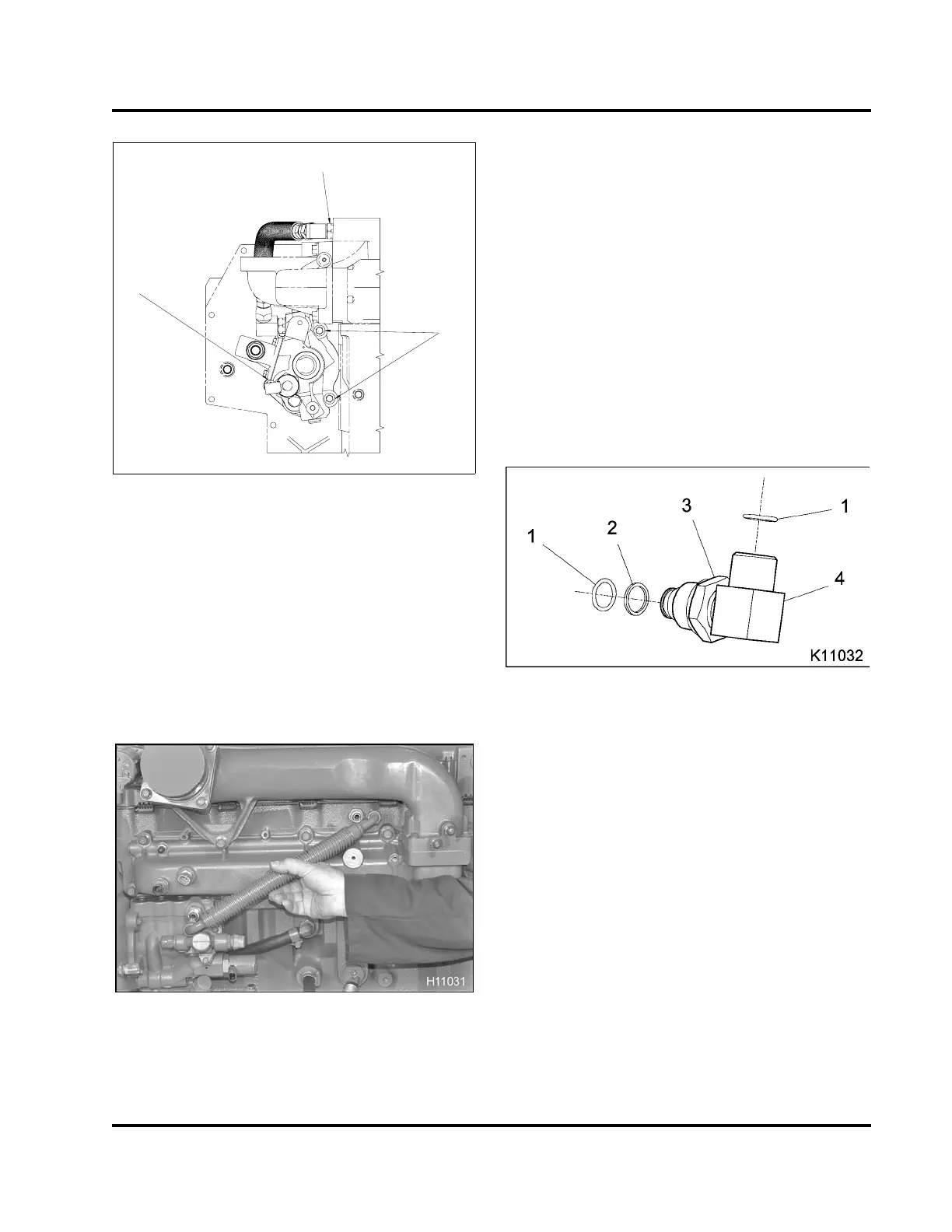

Figure 567 High-pressure oil elbow (typical)

1. O-ring seal (#14) (2)

2. Back-up ring

3. Elbow jam nut

4. Elbow

1. Rotate both elbow jam nuts all the way to the base

of the elbows.

2. Install new O-rings and back-up ring on the 70 and

90 degree elbows.

3. Lubricate new O-rings with clean engine oil.

CAUTION: To prevent engine damage, make all

adjustments to the high-pressure oil elbows within 15

minutes of applying Loctite®.

4. Apply two beads of Loctite® 246 Threadlocker

(Table 48) to the threads of both high-pressure oil

elbows.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...