358 FUEL SYSTEM

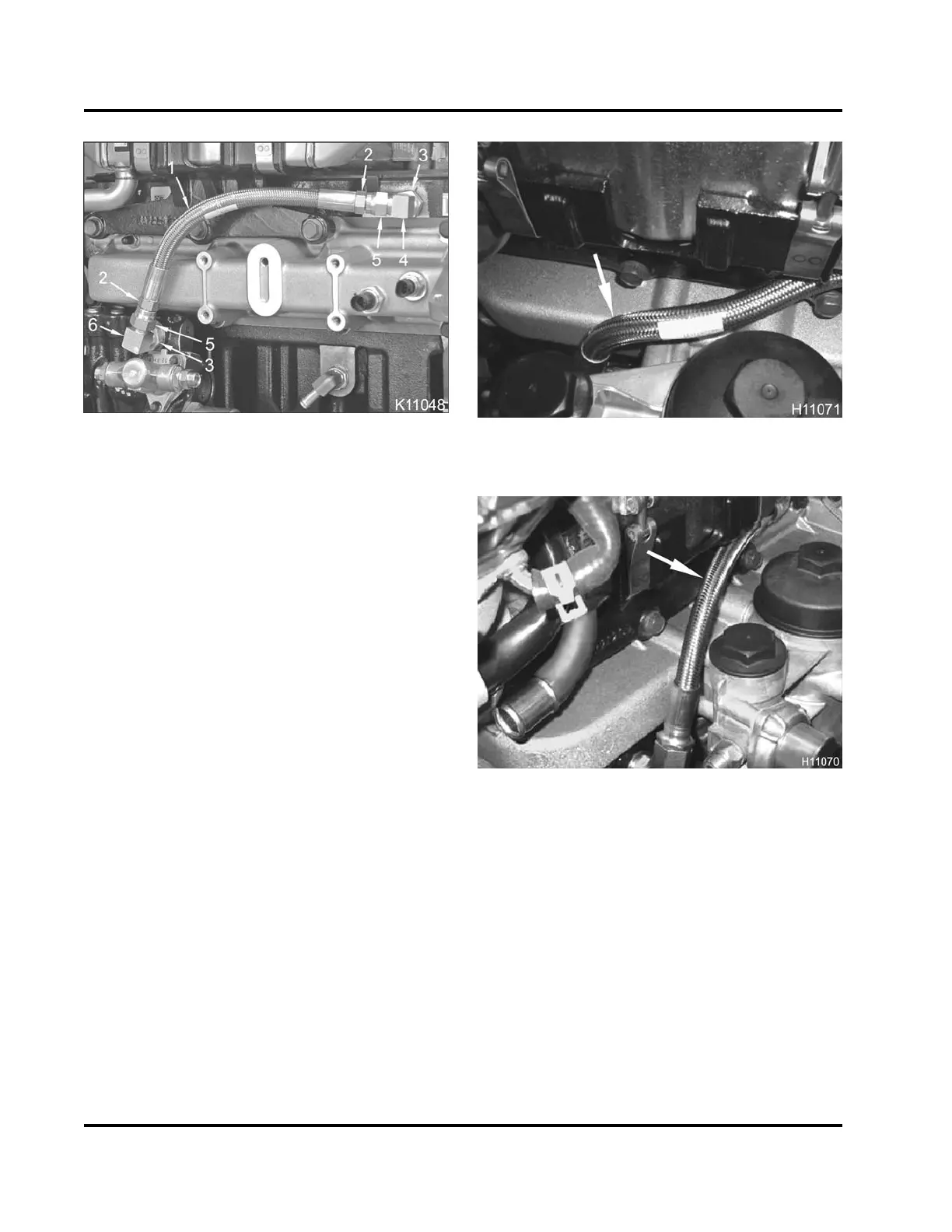

Figure 568 Good position and alignment of new

high-pressure oil hose (typical)

1. High-pressure oil hose

2. High-pressure oil hose nut (2)

3. Elbow jam nut

4. 70 degree elbow

5. Swivel nut (2)

6. 90 degree elbow

5. Install 70 degree elbow into high-pressure oil port

on intake side of the cylinder head. Run fitting all

the way in finger tight and then back fitting off (less

than one full turn) to orient fitting toward the front

of the engine.

6. Install 90 degree elbow into high-pressure oil

pump. Run fitting all the way in finger tight and

then back fitting off (less than one full turn) to

orient fitting.

7. Connect the high-pressure oil hose to the 70 and

90 degree elbows and finger tighten swivel nuts.

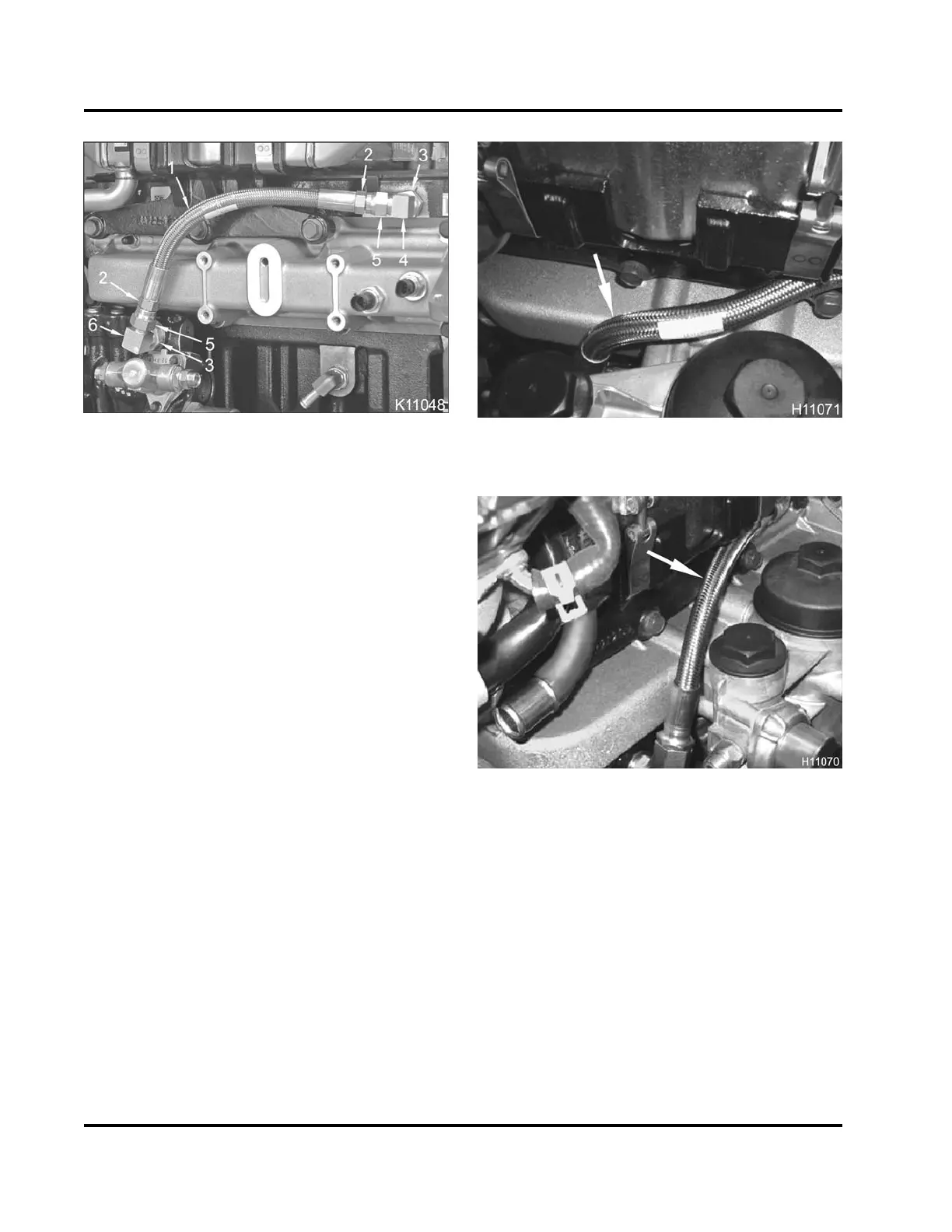

Figure 569 Bad alignment of high-pressure oil

hose (hose twisted)

Figure 570 Good alignment of high-pressure oil

hose (hose not twisted)

CAUTION: To prevent engine damage, the

high-pressure oil hose must be positioned and

aligned in a smooth arc, not twisted, under excess

tension or touching engine components.

8. Position and align the high-pressure oil hose, so

the hose is not under excess tension or twisted.

Tighten each swivel nut on the high-pressure

hose, using one wrench to hold the hose nut,

while using another wrench to tighten the swivel

nut to special torque value (Table 47).

9. Position and align the high-pressure oil hose, so

the hose is not under excess tension and the hose

bends in a smooth arc. Use one wrench to hold

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...