INTAKE, INLET, AND EXHAUST MANIFOLDS 83

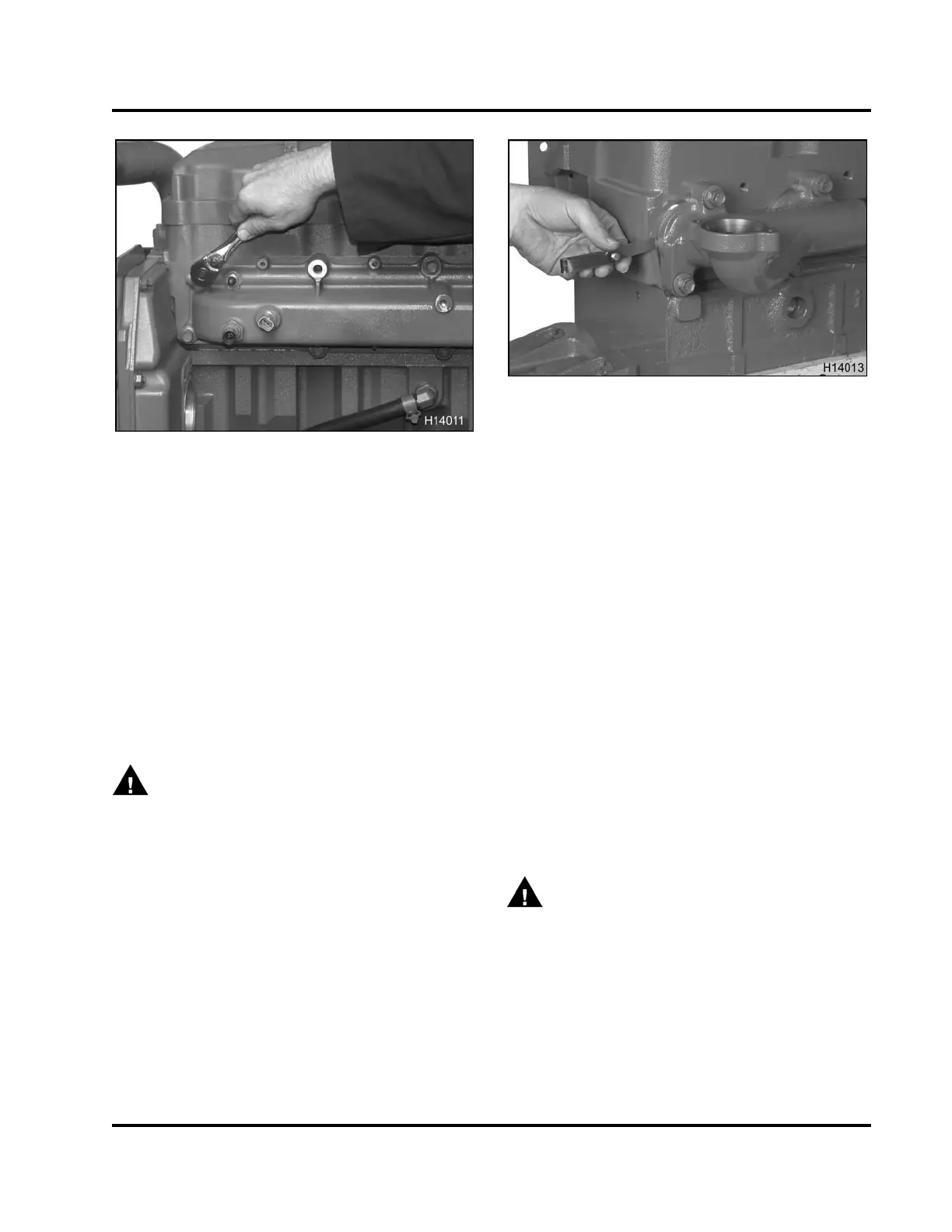

Figure 74 Intake manifold mounting bolts

5. Remove 13 intake manifold mounting bolts (M10

x35).

6. Remove intake manifold and gasket from the

engine. Discard gasket.

Cleaning and Inspection

Exhaust Manifold

1. Clean exhaust manifold thoroughl

y with a suitable

non-caustic solvent. Scrape off

excess scale and

rust from manifold surfaces.

WARNING: To prevent personal in

jury or

death, wear safety glasses w

ith s ide s hields.

Limit compressed air pressu

reto207kPa(30psi).

2. After cleaning, blow dry exh

aust manifold using

filtered compressed air.

3. Inspect manifold for cracks

or damage. Replace

manifold as necessary.

4. Check for warpage as follo

ws:

a. Install exhaust manifold

without the gasket

to a cleaned cylinder hea

dmatingsurface.

Torque 12 mounting bolts

(M12 x 35) to the

special torque value (T

able 8).

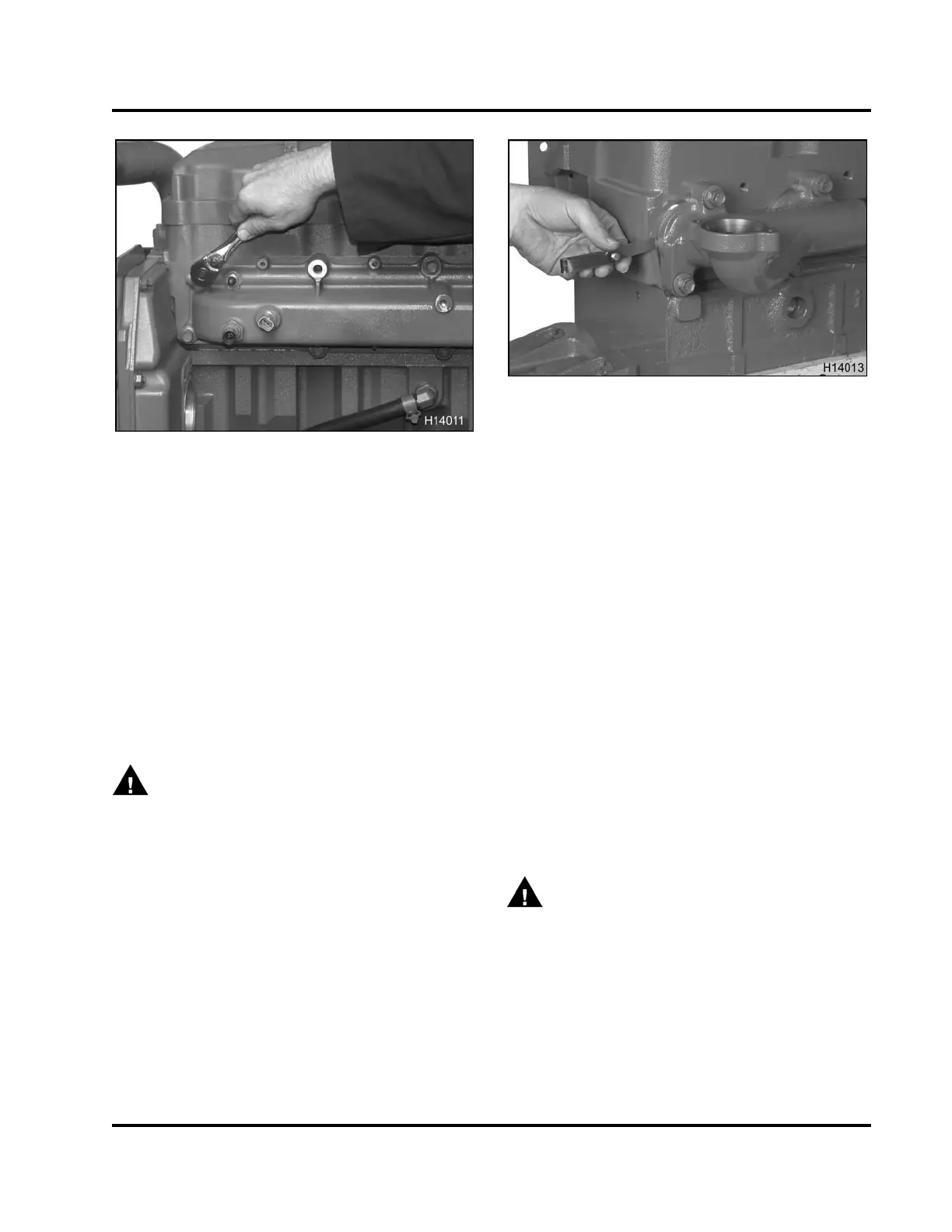

Figure 75 Checking exhaust manifold for cracks

and warpa ge

b. Use a 0.25 mm (0.010 in) feeler gauge

to measure the gap between the mating

surfaces of the manifold and engine. If the

feeler gauge passes through the gap, the

manifold must be resurfaced.

NOTE: A maximum of 0.64 mm (0.025 in) of

material can be ground off to correct

warpage.

c. Remove 12 bolts (M12 x 35) and manifold

.

d. If the warpage cannot be corrected by

grinding manifold mating surface, r

eplace

manifold.

Intake Manifold

CAUTION: To prevent engine damag

e, do not attempt

to grind or machine the intake ma

nifold to compensate

for a warped condition.

1. Clean intake manifold thorou

ghly with a suitable

non-caustic solvent.

WARNING: To prevent persona

l injury o r

death, wear safety glasses

with side shields.

Limit compressed air pre

ssure to 207 kPa (30 psi).

2. After cleaning, blow dry

using filtered compressed

air.

3. Check manifold for crack

s and damage. Replace

intake manifold as nece

ssary.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...