DIAMOND LOGIC® ENGINE BRAKE 401

Installation

High-pressure Oil Rail

1. Back off all valve lash adjustments. This must

be done to eliminate the possibility of additional

forces on the high-pressure oil rail when mounting

bolts are torqued.

CAUTION: To prevent engine damage, a new backup

ring and injector inlet seal must be installed on all six

injector oil inlet tubes.

CAUTION: To prevent engine damage, when

installing new backup rings, a new backup ring must

match the backup ring removed from the injector oil

inlet tubes.

2. Inspect injector oil inlet adaptors for internal

O-ring extrusion and high-pressure oil leak

paths. Verify that each oil inlet tube is moveable

.

Replace any adaptor having an extruded internal

O-ring, high-pressure oil leak path or seized oi

l

inlet tube.

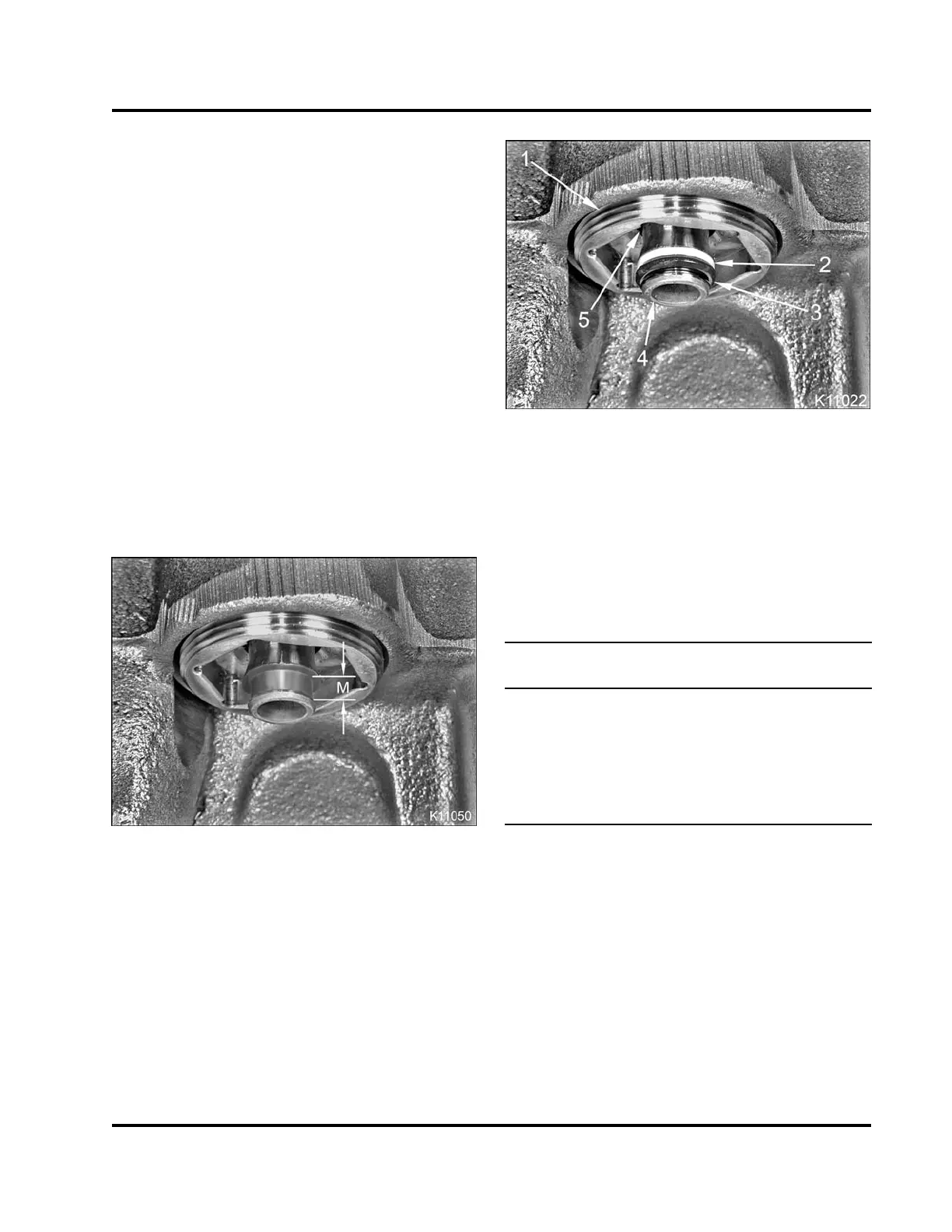

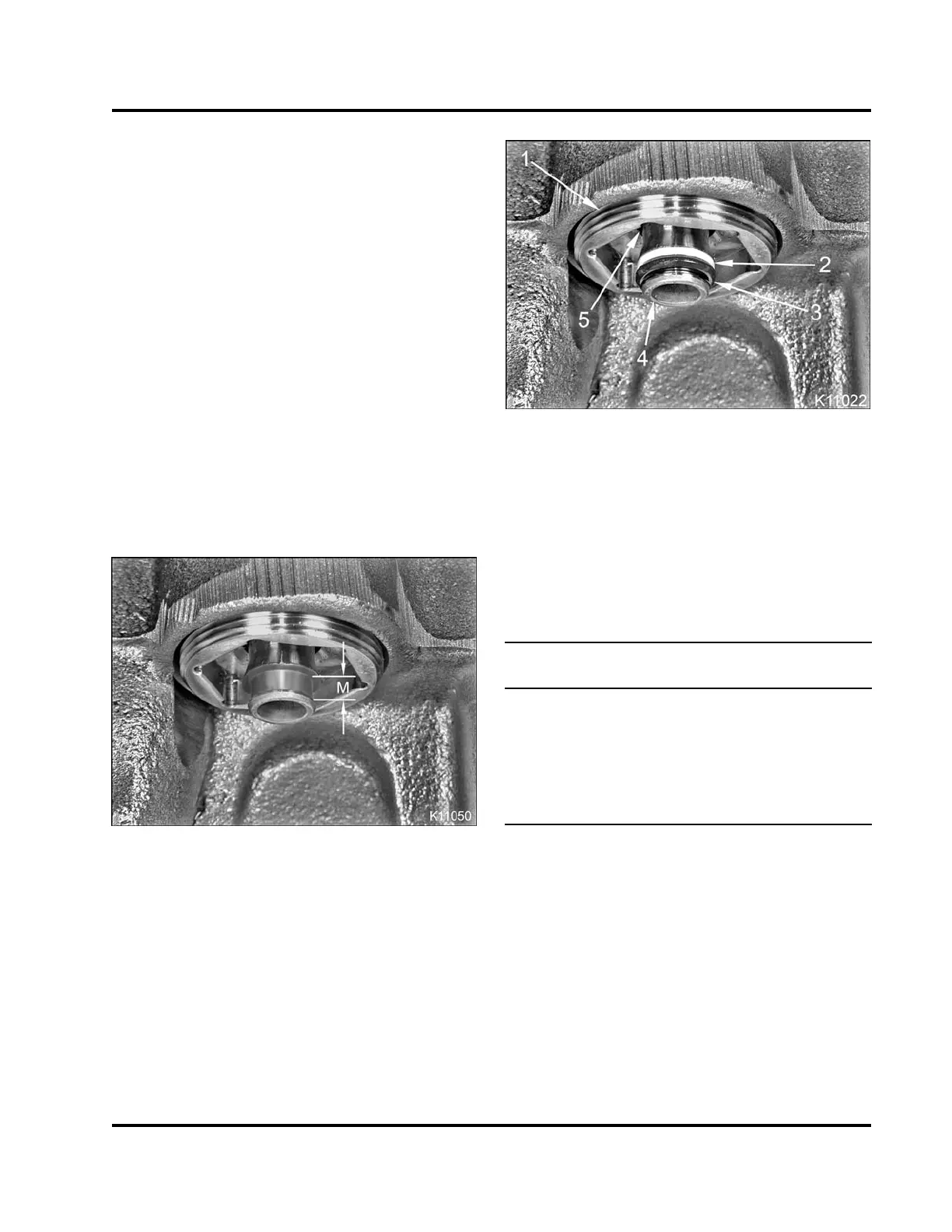

Figure 643 Groove Measure

ment (M) in injector

oil inlet tube

3. Measuregrooveinthein

jector oil inlet tube.

Figure 644 Injector oil inlet adapter installed in

high-pressure oil rail

1. Injector oil inlet adaptor

2. Backup ring

3. Injector oil inlet seal

4. Oil inlet tube

5. Internal O-ring (not serviceable)

Table53 GrooveMeasurement(M)inOilInlet

Tube and Required Backup Ring

Groov e (M) in Oil Inlet

Tube

Backup Ring

5.080 mm (0.200 in)

Backup ring 1.8 mm

(0.07 in)

4.877 mm (0.192 in)

Backup ring 1.6 mm

(0.06 in)

4.420 mm (0.174 in)

Backup ring 1.1 mm

(0.04 in)

4. Install a new backup ring onto injector oil inlet

tubes, according to the groove measurements

listed in the table.

5. Install new injector inlet seal onto injector oil inlet

tubes.

6. Coat backup rings and injector oil inlet seals with

clean engine oil.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...