POWER CYLINDERS 225

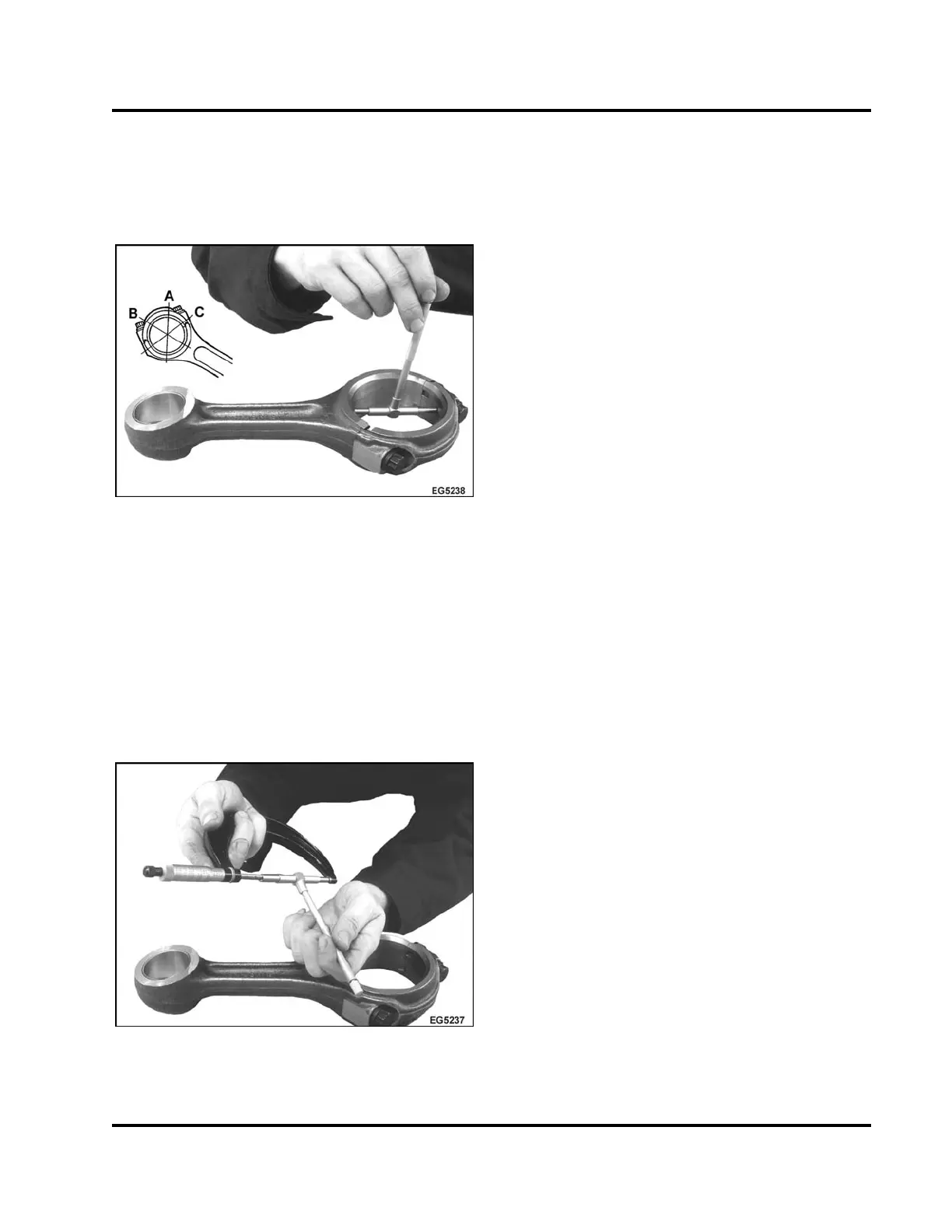

Connecting Rod Bearing Bore

1. Inspect the finished surface of the connecting

rod bearing bore for nicks, burrs, and scoring.

Replace connecting rod as required.

Figure 316 Connecting rod bearing bore for

out-of-round

2. Use an inside micrometer to measure the inside

diameter of the connecting rod bearing bore at

three locations that are 60 degrees apart. Record

the readings.

If the difference between measurement B and

the average of measurements A and C exceeds

the specification for out-of-round, replace the

connecting rod.

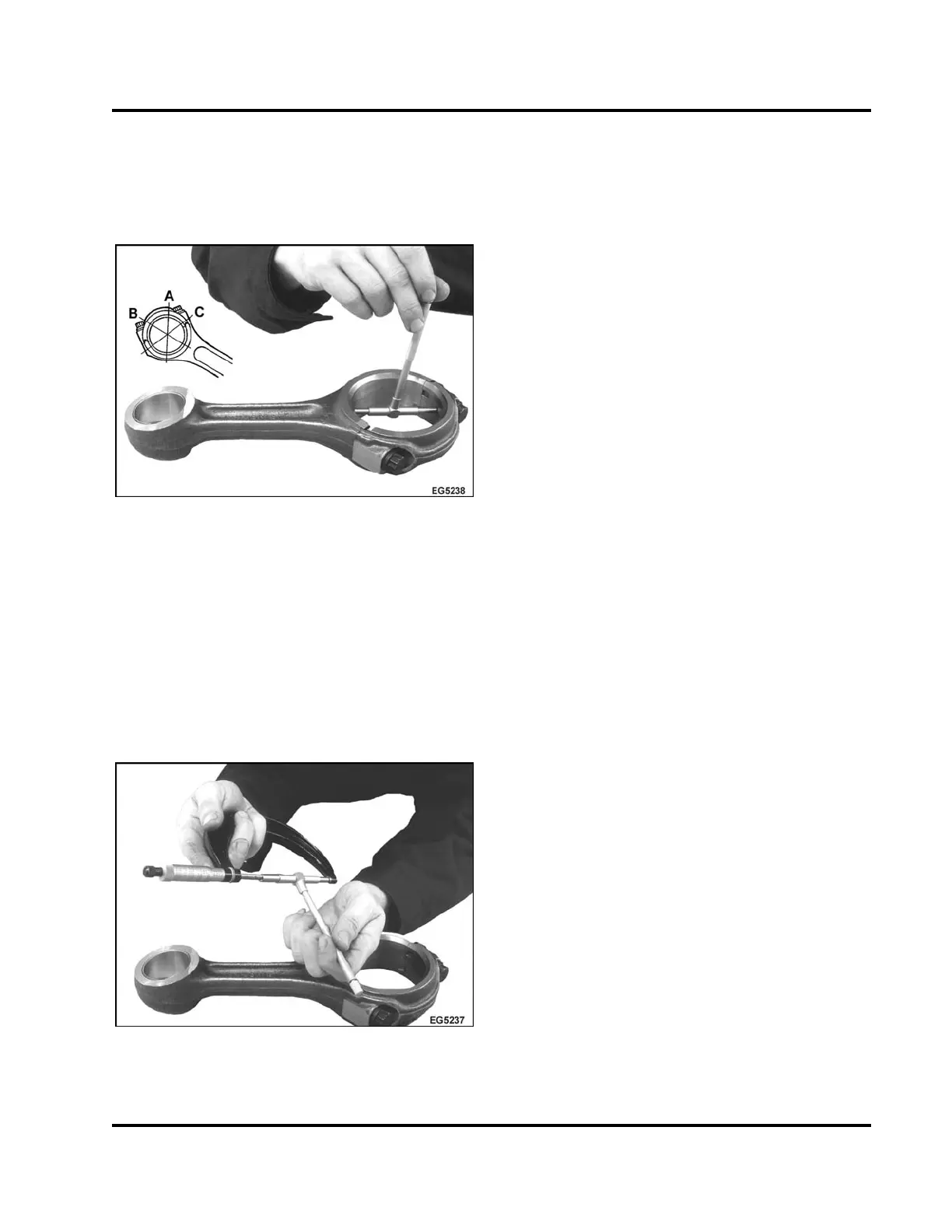

Figure 317 Measuring connecting rod bearing

bore taper

3. Use a telescoping gauge and an outside

micrometer to measure the inside diameter of

the connecting rod bearing bore at the edge of

each side of the bore. Record the readings.

If the difference between the two measurements

exceeds the bore taper specification, replace the

connecting rod assembly.

Bend and Twist

Engine component wear patterns can often be

identified and used to diagnose a problem. Some

common examples of connecting rod wear patterns

include the following:

• A shiny surface on the edge of the piston pin

bushing usually indicates that a connecting rod

is bent or a piston pin hole is not positioned

properly in relation to the piston skirt and piston

ring grooves.

• Abnormal wear on the connecting rod bearing

may indicate that a connecting rod is bent or the

bearing bore is too tapered.

• A twisted connecting rod will not create an

easily identifiable wear pattern, although

severely twisted connecting rods will disturb

the action of the entire piston and connecting rod

assembly and may be the cause of excessive oil

consumption.

If any of these conditions exist, use a suitable

alignment fixture to check the connecting rod for

bends and twists. Follow the instructions of the

alignment fixture manufacturer. If a bend or twist

exceeds the specification, replace the connecting

rod.

Bearing Fitting Procedures and Bearing Running

Clearance

CAUTION: To prevent engine damage, do not attempt

to reduce journal-to-bearing running clearance by

reworking the bearing cap or the bearings. Grind the

crankshaft to the next available under size or replace

crankshaft.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...