POWER CYLINDERS 229

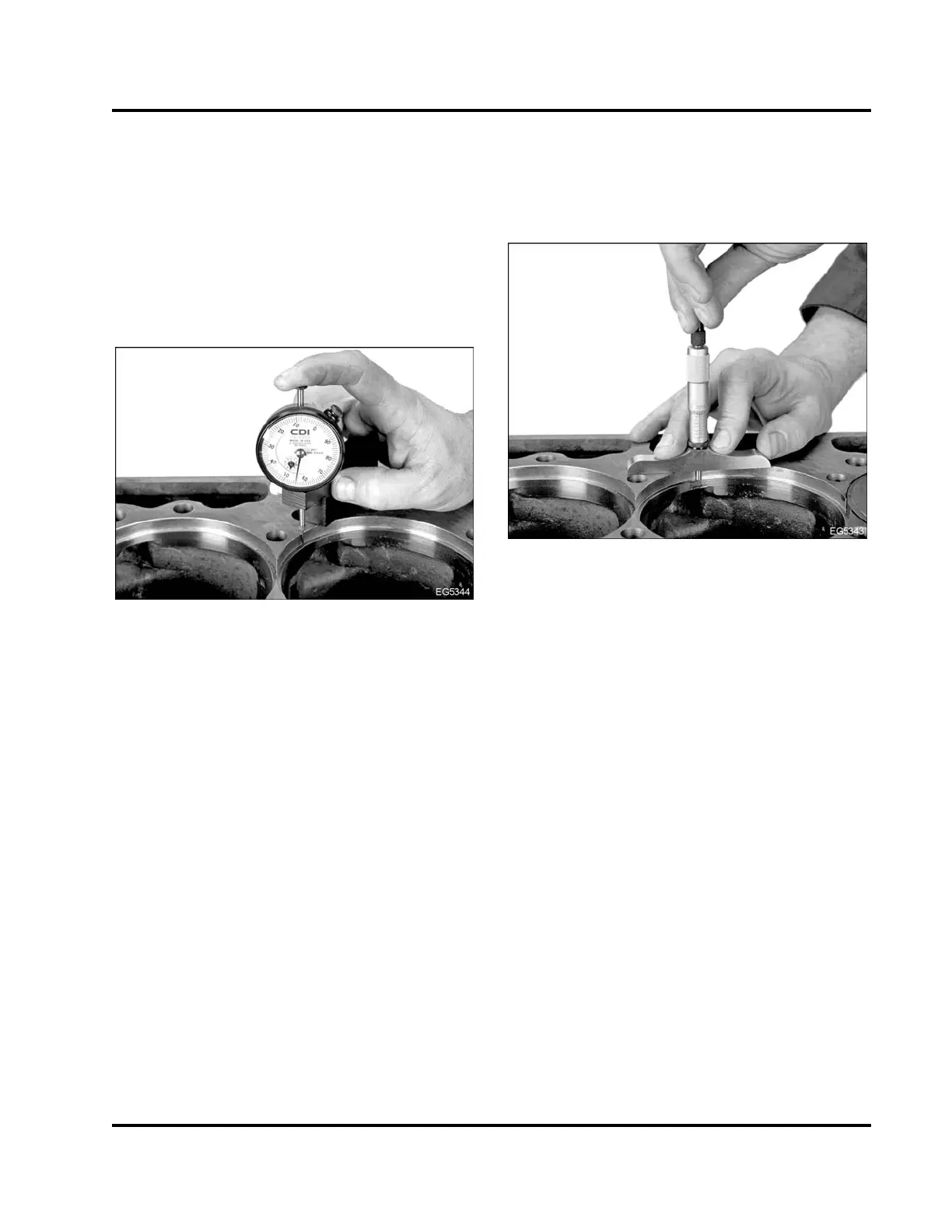

Checking Counterbore Depth

Use one of the following methods to check the depth

of the crankcase counterbore:

Surface Gauge Method

NOTE: Clean counterbore surface and remove

existing shims if any before measuring counterbore

depth.

Figure 325 Checking counterbore depth with

surface gauge

1. Place the indicator tip of the surface gauge on the

crankcase. Zero the dial indicator.

2. Move the indicator tip onto the counterbore ledge.

Record the counterbore depth reading on the dial

indicator.

3. Take counterbore depth measurements at four

evenly spaced locations around the counterbore

ledge.

4. Compare the counterbore depth variation

between the four measurements with those

listedinspecifications (Table 32).

If the maximum variation between the four

measurements exceeds the specification,

resurface the counterbore.

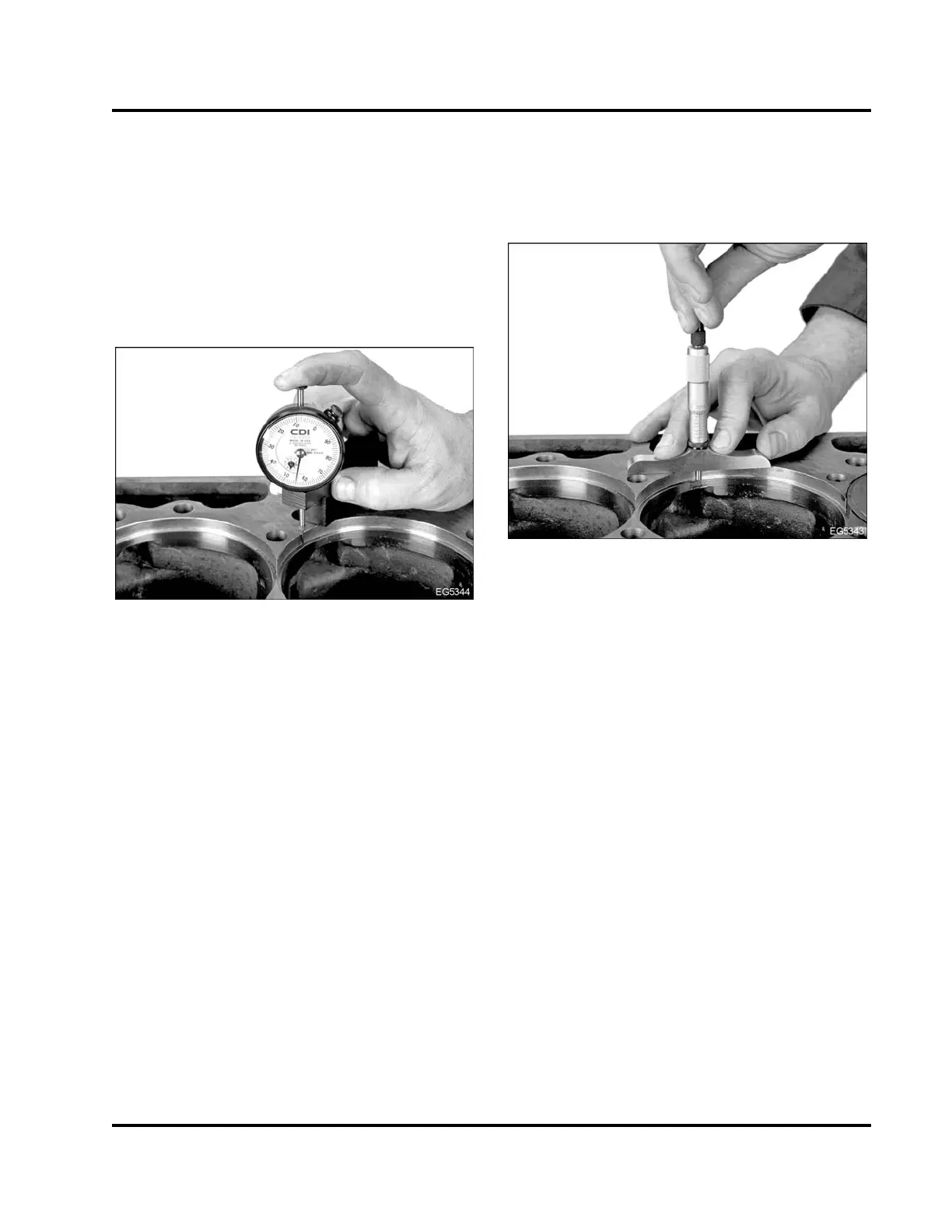

Depth Micrometer Method

NOTE: Clean counterbore surface and remove

existing shims if any before measuring counterbore

depth.

Figure 326 Checking counterbore depth with

depth micrometer

1. Place a depth micrometer onto the counterbore

ledge. Record the counterbore depth reading.

2. Take counterbore depth measurements at four

evenly spaced locations around the counterbore

ledge.

3. Compare the counterbore depth variation

between the four measurements with

specifications.

If the maximum variation between the four

measurements exceeds the specification,

resurface the counterbore.

Checking Cylinder Sleeve Protrusion

CAUTION: To prevent engine damage, do not apply

holding adapters to the "fire dam" ridge of the cylinder

sleeve. Clamping forces should not be applied to this

ridge as internal cracking could develop adjacent to

the shim land.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...