230 POWER CYLINDERS

1

2

3

4

5

6

H06089

Figure 327 Cylinder sleeve clamping details

1. Fire dam (highest point on cylinder sleeve)

2. Clamping tool (washer)

3. Clamping bolt

4. Crankcase

5. Cylinder sleeve

6. Shim pack

1. Clean the cylinder sleeve, cylinder sleeve crevice

bore, and crankcase counterbore surface.

CAUTION: To prevent engine damage, do not

"torque-to- yield" the holding adapter bolts (as

when installing cylinder head bolts). This will

prevent stretching the bolts and risking the

indentation of tooling marks on the cylinder

sleeve.

2. Install the cylinder sleeve in the cylinder bore

without the crevice seal.

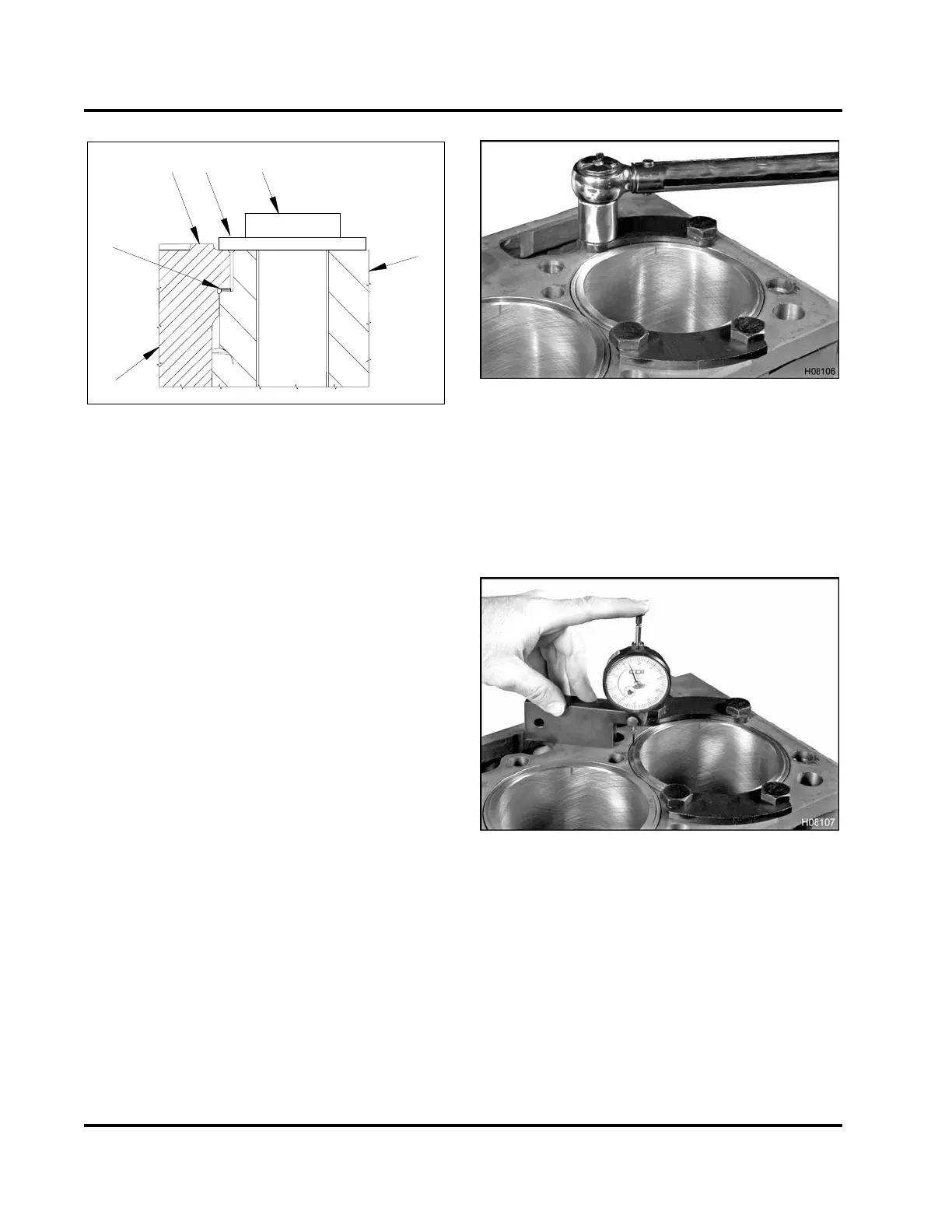

Figure 328 Installing the holding adapters

3. Install the cylinder sleeve holding adapters (Table

34) with 10.9 or higher grade bolts and hardened

washers. Tighten bolts in two stages:

A. 55 N·m (40 lbf·ft)

B. 110 N·m (80 lbf·ft)

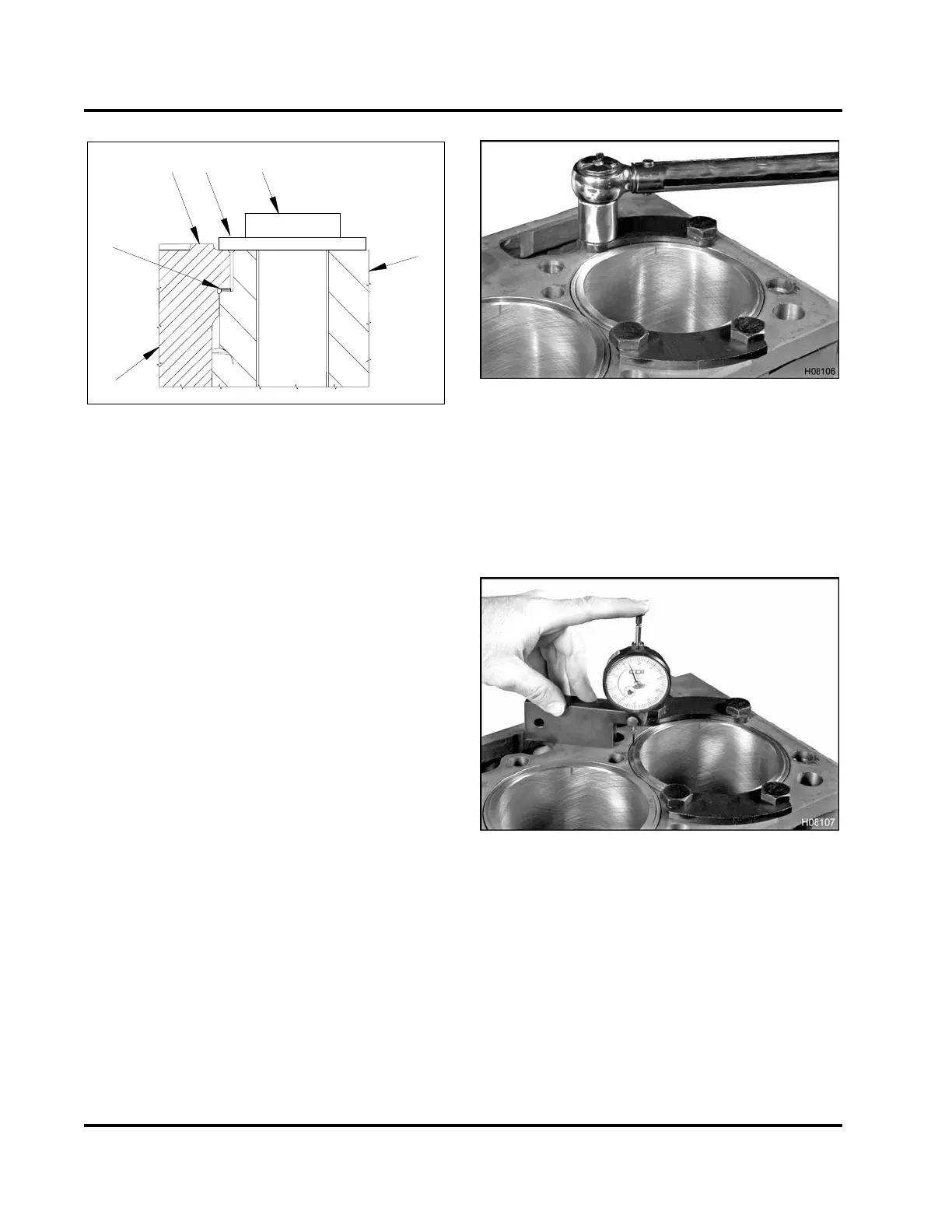

Figure 329 Measuring cy

linder sleeve protrusion

4. Place the indicator ti

pofasurfacegaugeonthe

cylinder sleeve flan

ge. Zero the dial indicator.

5. Move the surface gaug

e until the indicator

tip slides off the fla

nge to the surface of the

crankcase. Record t

he cylinder sleeve protrusion

reading on the dial

indicator.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...