POWER CYLINDERS 231

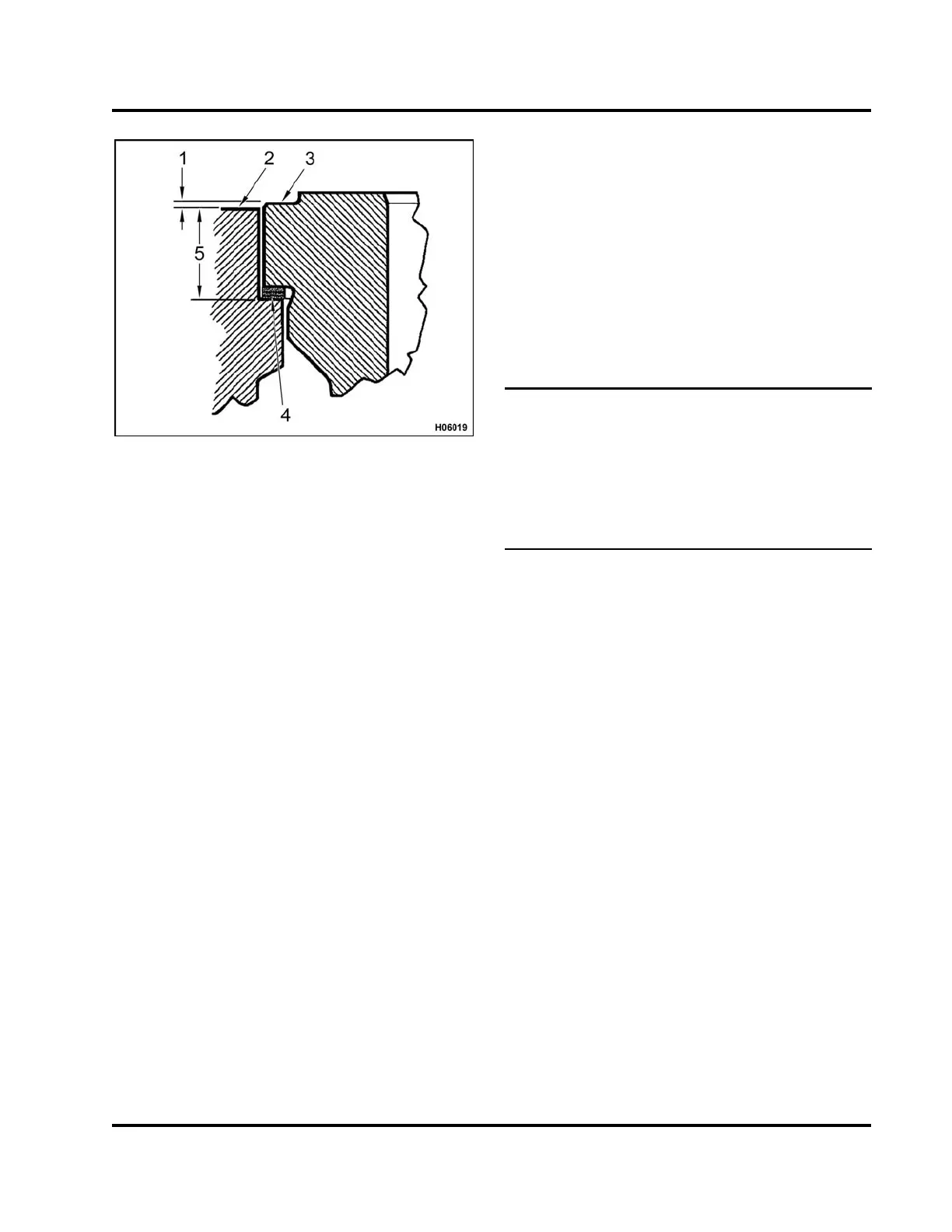

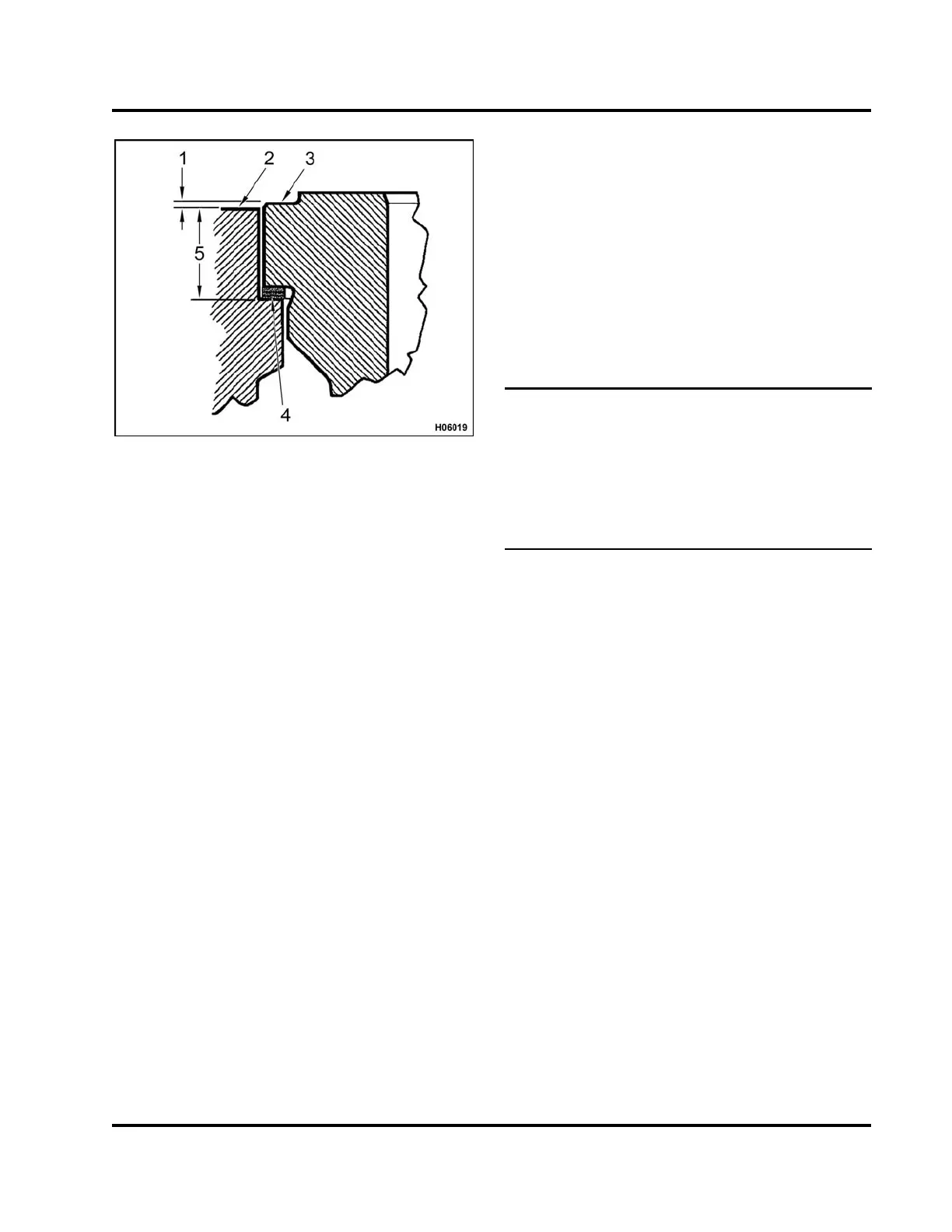

Figure 330 Checking cylinder sleeve protrusion

1. Cylinder sleeve protrusion

2. Top surface of crankcase

3. Cylinder sleeve flange

4. Shim to suit

5. Counterbore

6. Take cylinder sleeve protrusion readings from

three evenly spaced locations around the cylinder

sleeve. Average the three readings to determine

the cylinder sleeve protrusion.

If the cylinder sleeve protrusion does not meet

the specification, remove the cylinder sleeve and

install the necessary amount of shims to meet the

specification.

NOTE: Shims are available as a package consisting

of the following:

Table 27 Cylinder Sleeve Shim Sizes

Shim size (mm) Shim size (in)

0.05 0.002

0.10 0.004

0.25 0.010

0.51 0.020

0.81 0.032

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...