136 CYLINDER HEAD AND VALVE TRAIN

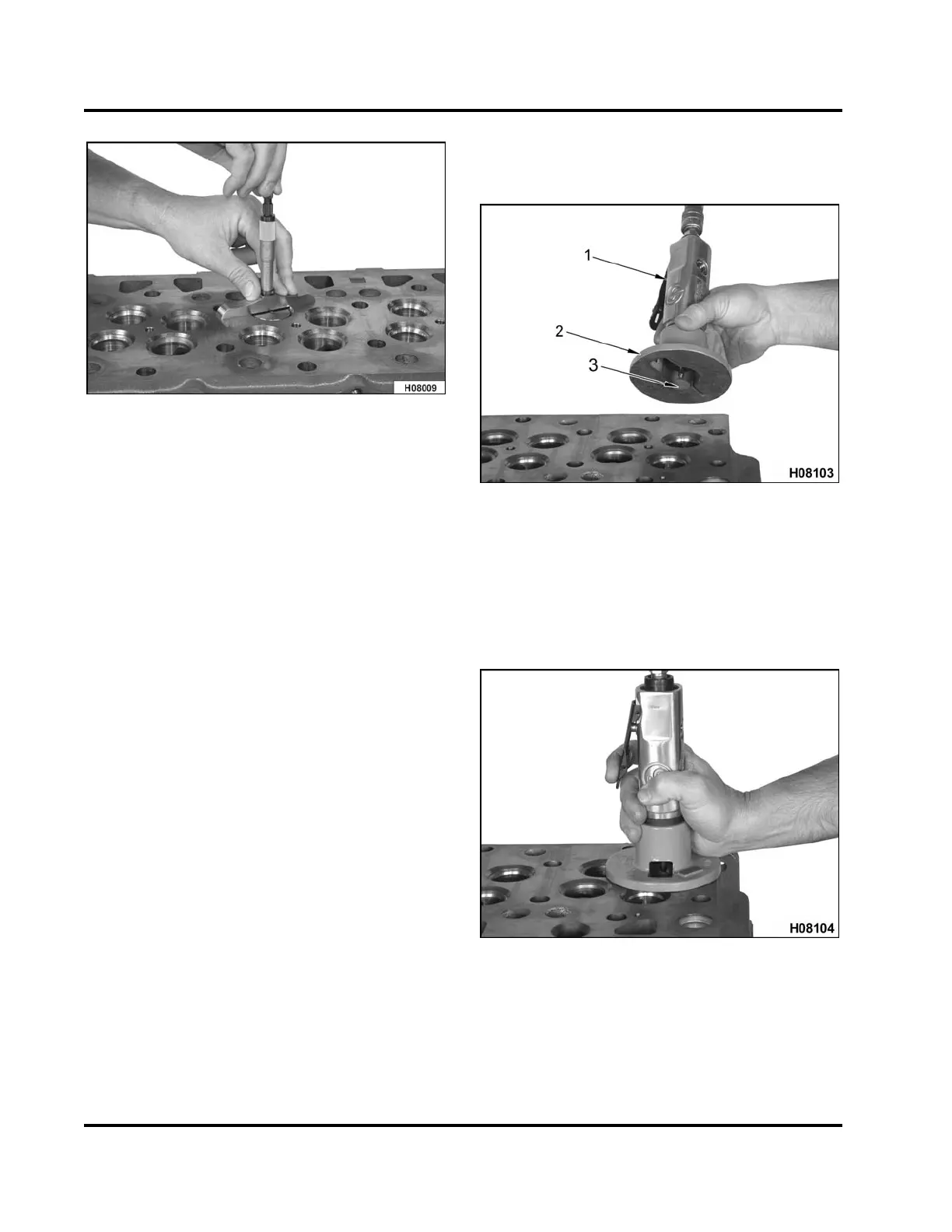

Figure 177 Checking valve recession

6. Install valve in guide. Use a depth micromete

r

to check valve recession. If valve recessio

n

is excessive, install a new valve or replac

e

valve seat as necessary. If the valve prot

rudes

above the surface of the cylinder head, re

grind

the valve seat. After grinding the va

lve seat,

check valve seat width again. Also c

heck the

valve face-to-valve seat contact

(Checking Valve

Face-to-Valve Seat Contact, page

134).

7. Use an appropriate dial indicator

to check

the valve seat runout. If runout e

xceeds

specifications, replace valv

eseat.

Replacing Valve Seats

Removal

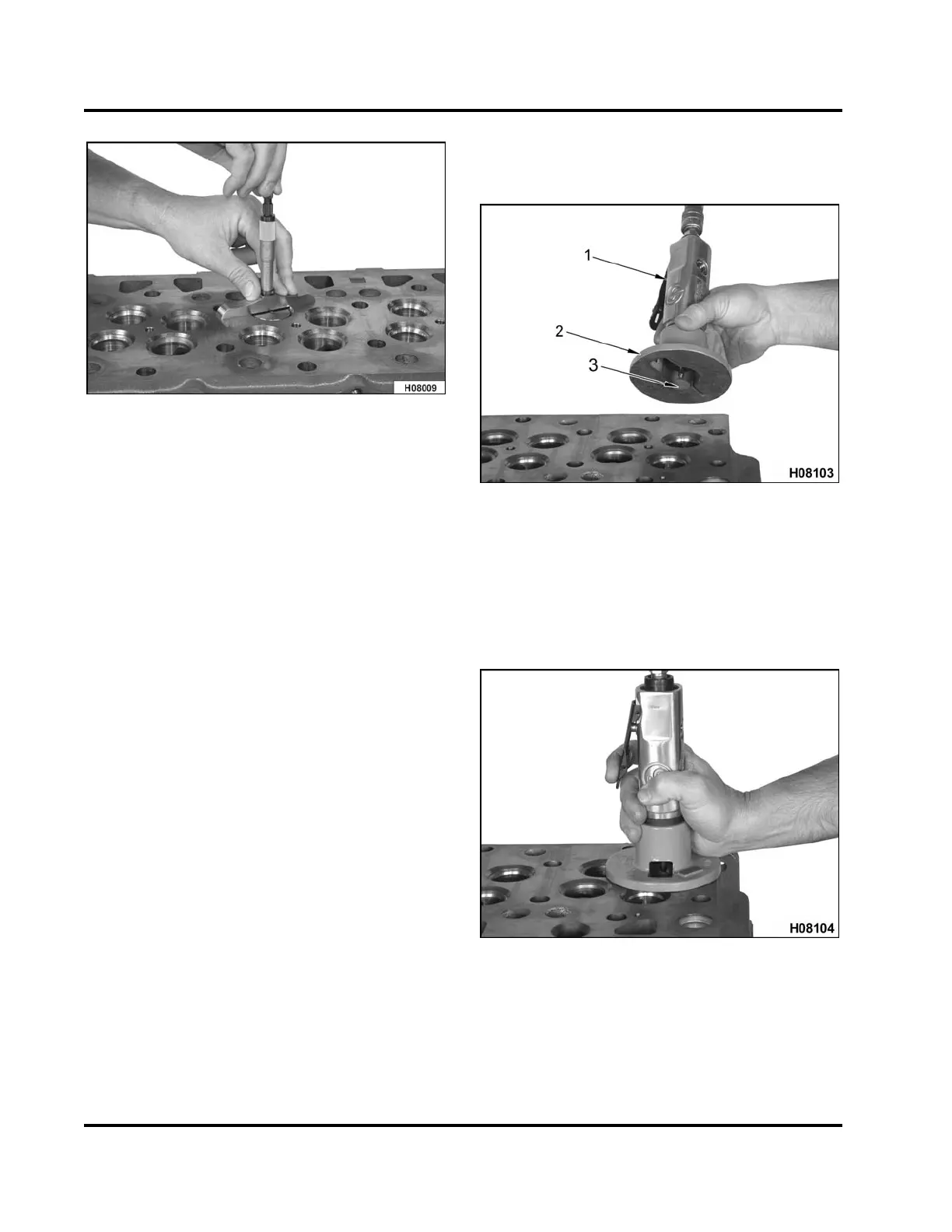

Figure 178 Grinding group tool

1. Air motor

2. Grinding base

3. Grinding wheel

1. Use grinding group tool (Table 17) to cut a groove

in the valve seat insert.

Figure 179 Grinding groove in valve seat

2. Position the appropriate size extractor in the valve

seat.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...