POWER CYLINDERS 227

8. Remove the Plastigage® material. Repeat the

test for each connecting rod bearing.

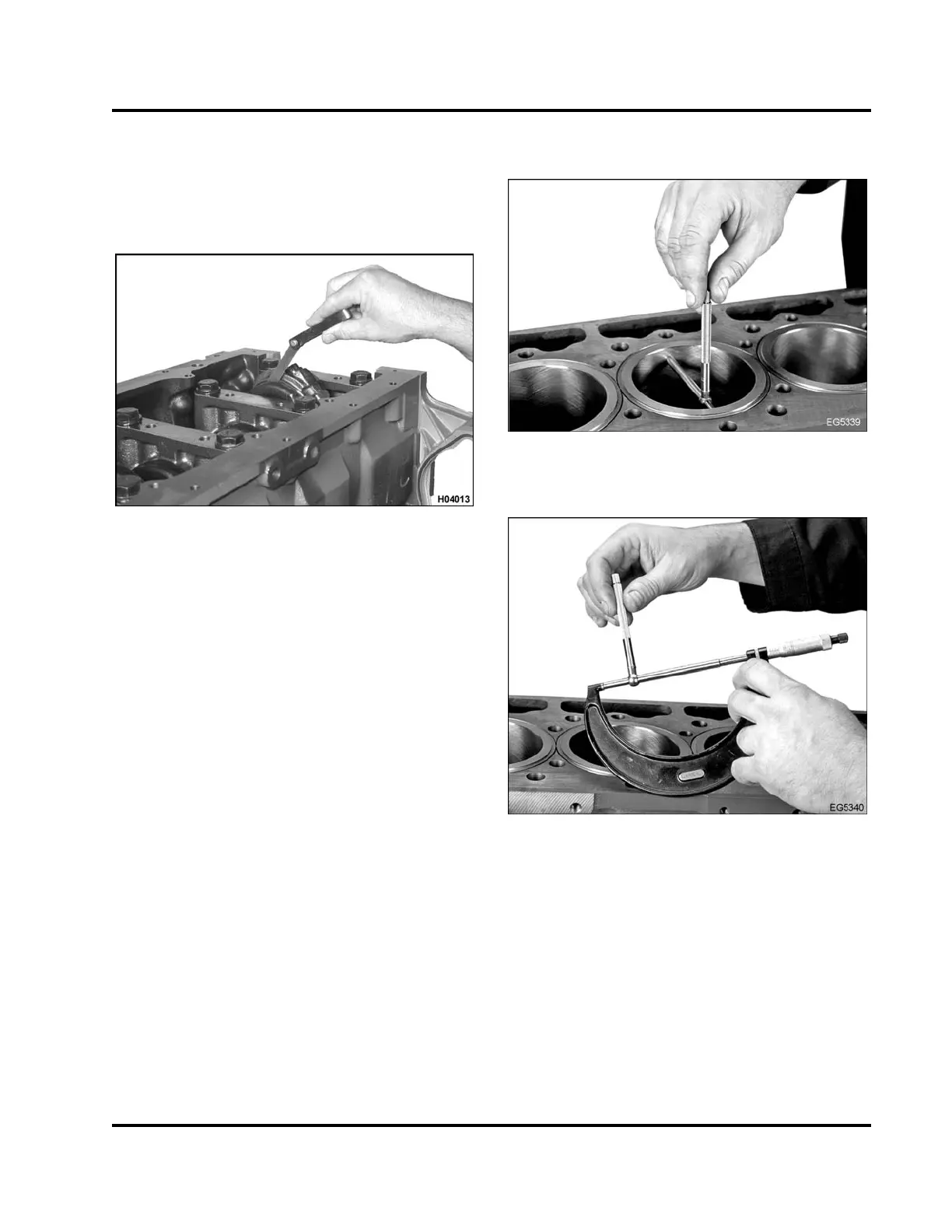

Connecting Rod Side Clearance

Figure 320 Measuring connecting rod side

clearance

Place a feeler gauge between the connecting rod and

crankshaft journal. This is the connecting rod side

clearance.

If there is too little side clearance, the connecting

rod may be damaged or the bearing may be out

of position. If there is too much clearance, the

connecting rod or crankshaft may be damaged.

Checking Cylinder Sleeves

1. Inspect the inside surface of the cylinder sleeves

for scuffing, scoring and polishing. Inspect

the outside surface for cavitation. Replace the

cylinder sleeves with piston rings as required.

2. To check the cylinder sleeves for wear (taper), use

one of the following methods:

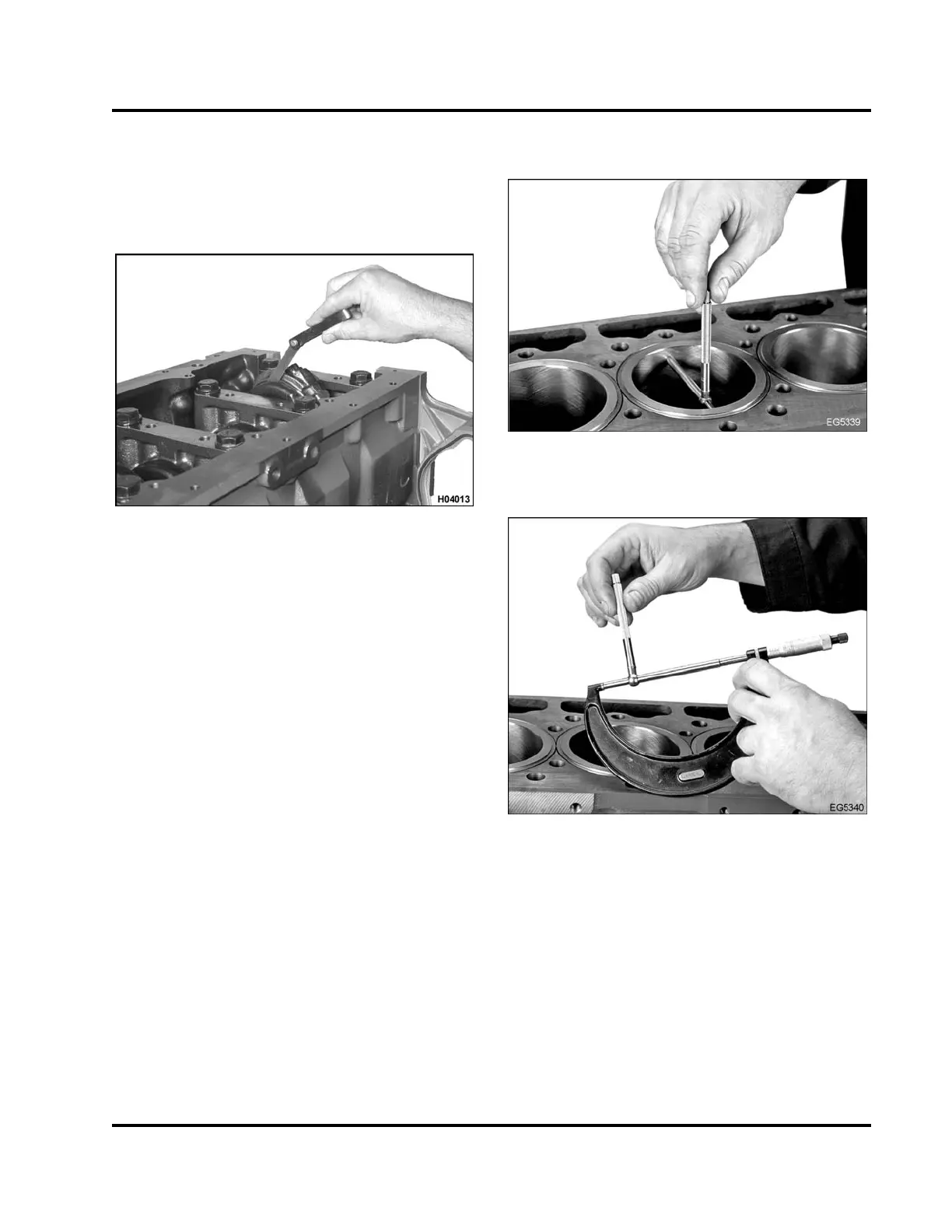

Telescoping Gauge Method

Figure 321 Checking cylinder sleeve inside

diameter with telescoping gauge

Figure 322 Measuring telescoping gauge

a. Use a telescoping gauge and an outside

micrometer to measure the inside

diameter of each cylinder sleeve at the

topofpistonringtravelandbelowthe

area of piston ring travel. Record the

readings.

b. Subtract the lower reading from the

higher reading. The result is the cylinder

sleeve taper.

If the result exceeds the specification,

replace the cylinder sleeve.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...