FRONT COVER AND RELATED COMPONENTS 163

DT 570 and HT 570 E ngines Only

Method One – Using a Feeler Gauge

1. Rotate the engine to approximately TDC (Top

Dead Center) compression on No. 1 cylinder (no

valves open). Set the lash on the No. 1 intake

valve to the nominal lash setting of 0.48 mm

(0.019 in).

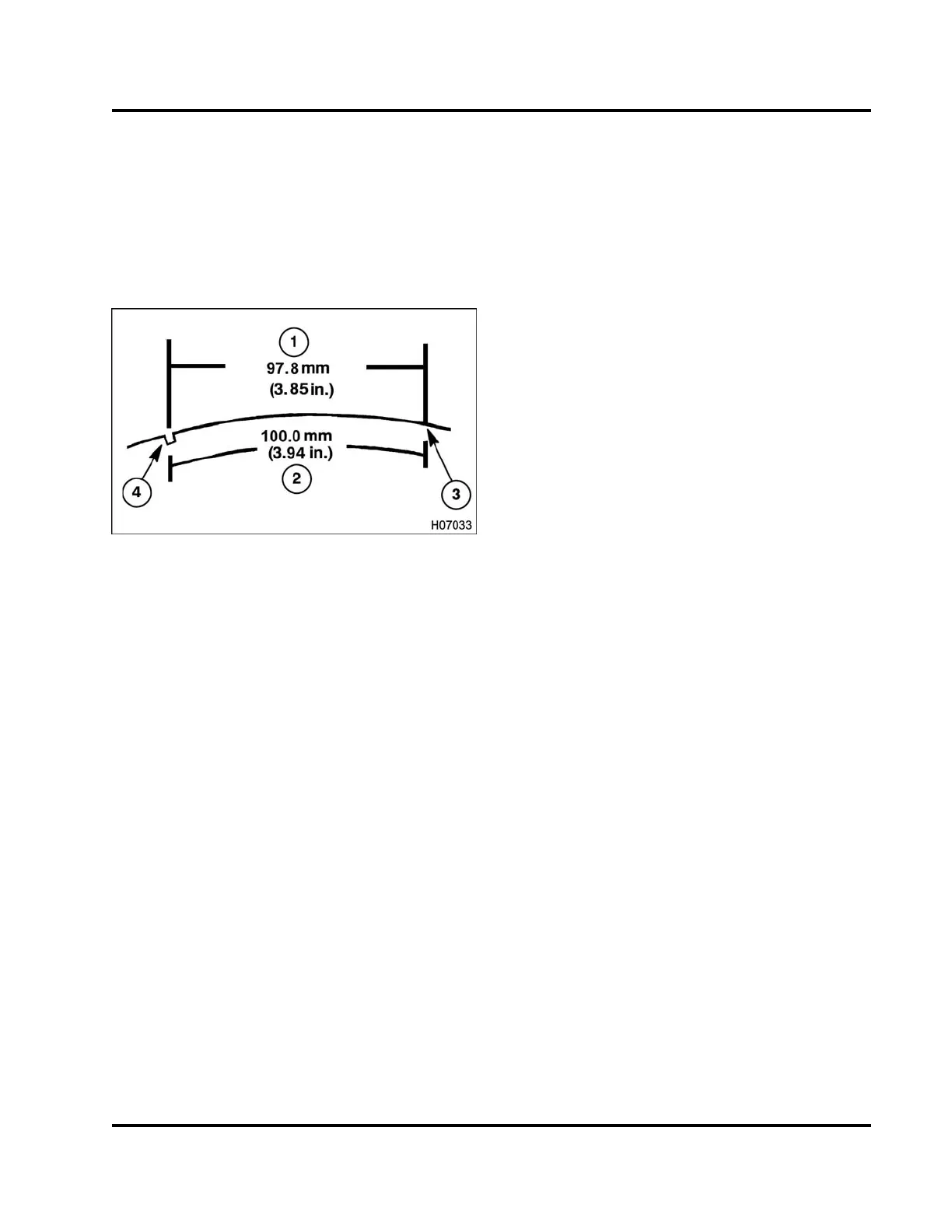

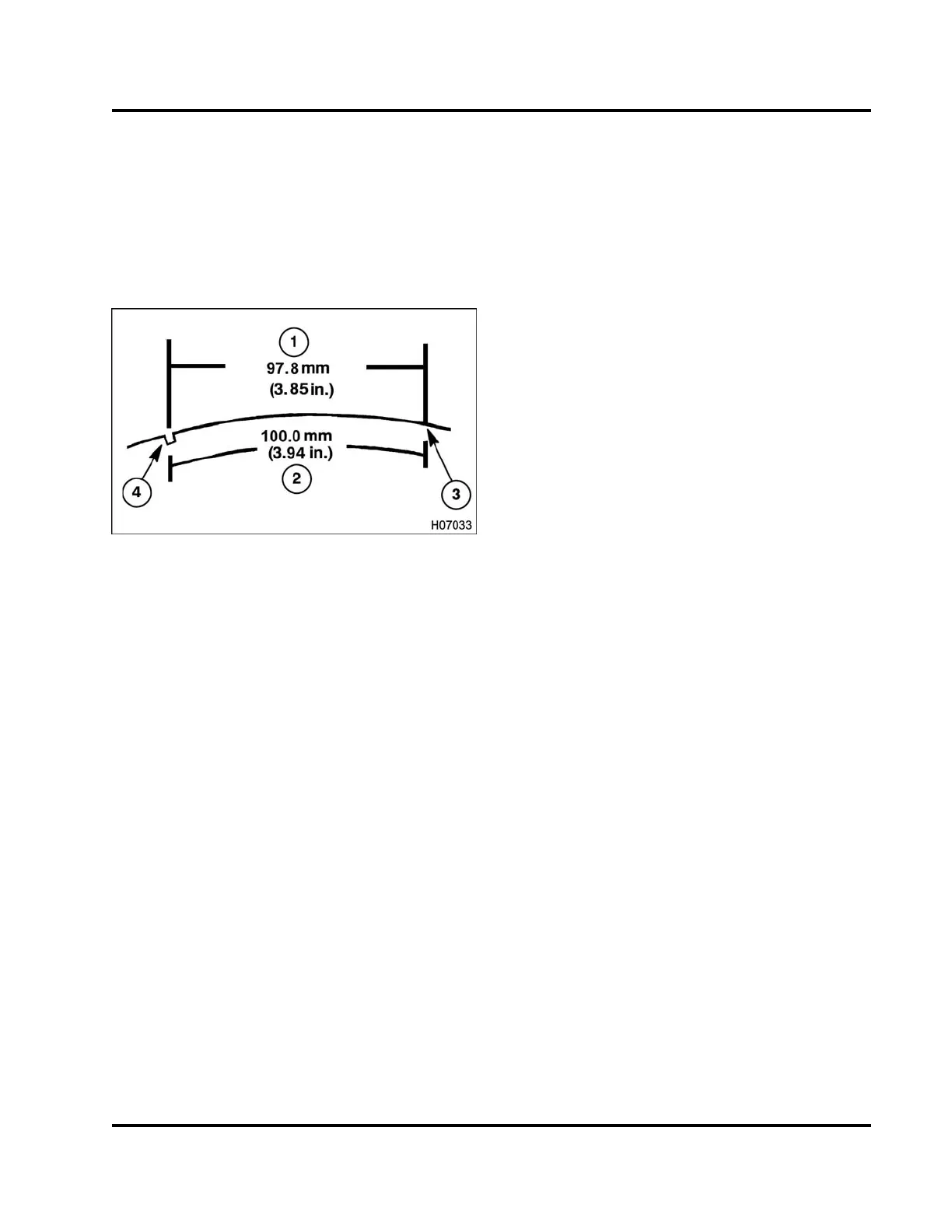

Figure 211 Checking Engine Gear Train Tim

ing

1. Straight line dimension

2. Radial distance dimension

3. Scribe mark

4. Damper timing notch

2. Scribe a mark on the damper pulley at a

radial

distance of 100.0 mm (3.94 in) or a str

aight line

distance of 97.8 mm (3.85 in) clockw

ise from

the timing notch as viewed from the

frontofthe

engine.

3. Place a 0.28 mm (0.011 in) feeler

gauge between

therockerarmandthevalvebri

dge of the No. 1

intake valve. Slowly rotate t

he engine forward

(clockwise) until the intake

valve starts to lift and

the feeler gauge becomes tig

ht. The mark should

lineupwiththeTDCarrowonthefrontcoveror

be within 3.5 crankshaft degrees of it. 3.5 crank

degrees is equivalent to a radial (or straight) line

distance of 8.1 mm (0.32 in) at the damper pulley.

NOTE: One tooth “out of time” on the gear train equals

approximately 11 degrees of movement or 21.4 mm

(27/32 in) of radial distance of damper pulley.

4. If the timing on the No. 1 valve is within

specifications, the other valves, barring extreme

camshaft lobe wear or poor adjustment, will also

be in time. If timing is found to be incorrect,

removal of the front cover is required to inspect

the punch marks on the gear train.

Method Two – Using a Dial Indicator

1. Adjust the No. 1 intake valve with the No. 1 piston

set at TDC (Top Dead Center) compression stroke

to 0.48 mm (0.019 in). Install a 0.28 mm (0.011

in) feeler gauge between the rocker arm and the

valve bridge of the No. 1 intake valve.

2. Position the magnetic base dial indicator on the

valve cover fence of the cylinder head rail with the

indicator tip on the No. 1 intake rocker arm tip.

3. Zero the dial indicator.

4. Rotate the engine approximately one full

revolution in either direction to a position 360

degrees from starting point.

5. The dial indicator should read within the range of

0.13-0.25 mm (0.005-0.010 in) from the starting

position for proper gear train timing.

6. If dial indicator readings are found to be outside of

this range, removal of the front cover is required

to inspect the punch marks on the gear train.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...