CRANKCASE, CRANKSHAFT, AND CAMSHAFT 261

Cleaning and Inspection

Cleaning the Crankcase

CAUTION: To prevent engine damage, the oil cooler

must be replaced if there was a bearing failure. Debris

from a bearing failure cannot be removed from the oil

cooler.

NOTE: The best way to clean the crankcase during

engine overhaul is in a chemical bath or hot tank.

This removes all carbonaceous material and mineral

deposits that collect in the cooling passages. If the

hot tank is not available, use the following cleaning

procedure.

1. Clean all old gasket material from the surfaces of

the crankcase, if any.

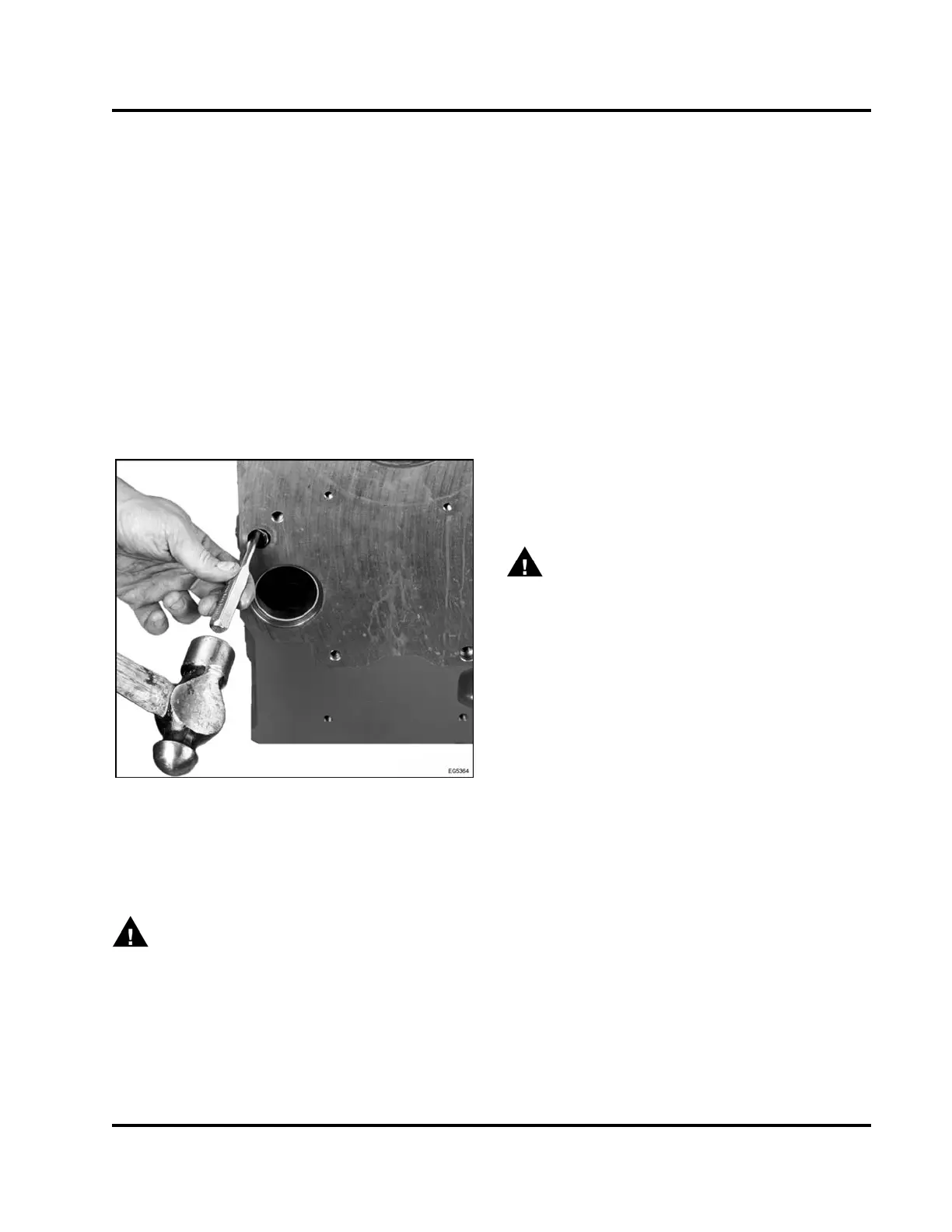

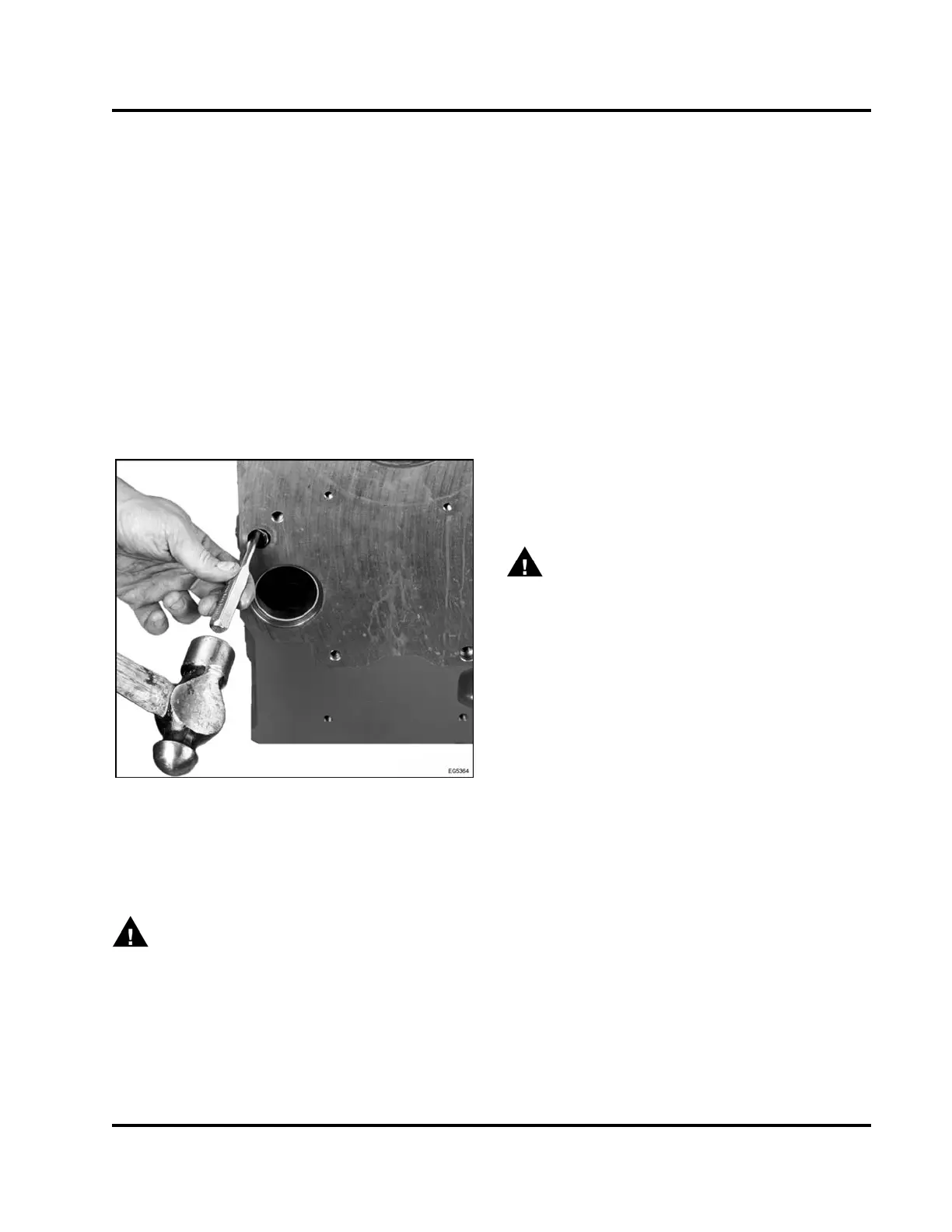

Figure 374 Removing crankcase plugs

2. Remove the main oil gallery cup plug, located at

the rear of the crankcase by using a hammer and

chisel. Knockout main oil gallery cup plug.

WARNING: To prevent

personal injury or

death, wear safety

glasses with side shields.

Limit compressed a

ir pressure to 207 kPa (30 psi).

3. With the plugs remo

ved from the crankcase, clean

the crankcase as fo

llows:

a. Use a nylon brush (

Table 40) with soap and

water to clean oi

l galleries.

b. Clean cross drillings using a nylon brush

(Table 40) with soap and water.

c. Use filtered compressed air to blow out oil

galleries and cross drillings.

d. Clean all threaded holes with an appropriately

sized tap (Table 40).

4. Install a new main oil gallery cup plug as follows:

a. Clean the mating surfaces of the plug and

crankcase.

b. Apply Loctite® 262 to the outside edge of the

cup plug.

c. Useanarbortodrivethecupplugin. The

arbor must be approximately 6 mm (1/4 in)

smaller in diameter than the plug that is being

installed.

d. Recess the cup plug 3.2 mm (1/8 in).

5. Install new plugs in the rear of the crankcase.

WARNING: To prevent personal injury or

death, wear safety glasses with side shields.

Limit compressed air pressure to 207 kPa (30 ps

i).

6. Inspect the piston cooling tubes for damage an

d

blockage as follows:

a. Inspect both ends of the tube. Verify that

the flanged end next to the bearing saddle i

s

intact and the orifice end protruding fro

mthe

crankcase is not broken. Replace any tub

es

that are damaged.

b. Hold tube under running water in a sink.

Water should stream out of tube end.

If not,

blockage will have to be physicall

y removed

by compressed air or piston oil tub

emustbe

replaced.

Crankcase Ventilation

1. Place breather and tubing asse

mbly (Figure 360)

into a solvent parts cleaner a

nd disassemble.

2. Thoroughly clean all hoses, cl

amps, tubing,

check valve and breather asse

mbly. Run solvent

through each end of the check v

alve to confirm

directional flow.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...