CYLINDER HEAD AND VALVE TRAIN 129

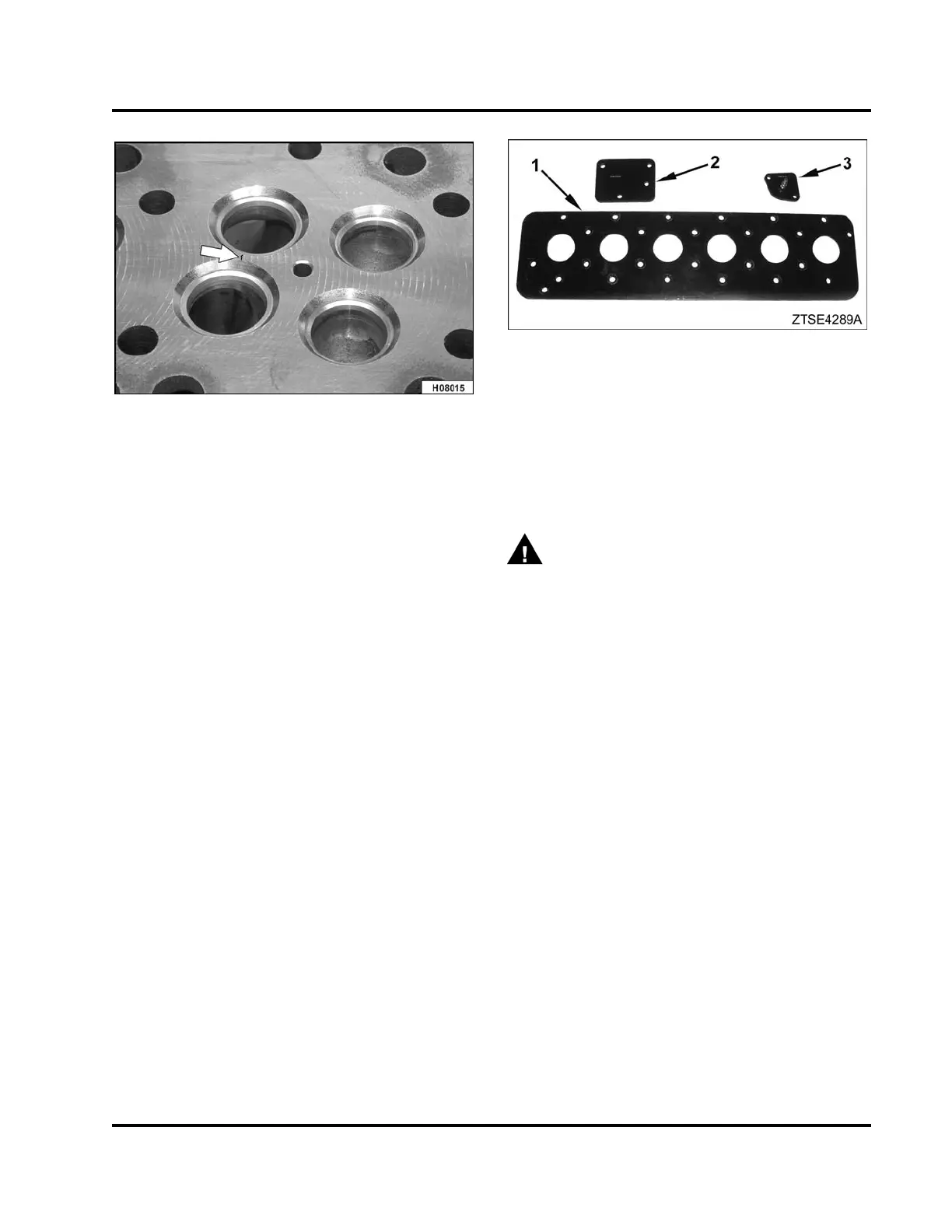

Figure 158 Crack in cylinder head

NOTE: Any cracks will show up as purple lines a

gainst

the white developer. If any cracks are prese

nt, replace

the cylinder head.

Pressure Check Cylinder Head

Pressure testing the cylinder head will

reveal cracks

in ports or sleeve leakage which cannot

be observed

using dye penetrant. Pressure-test t

he cylinder head

as follows:

1. Install fuel injectors into cylinder

head injector

bores and secure. Refer to Fuel Injec

tors (Fuel

Injectors, page352) for installati

on procedure.

2. Remove the valves, using a valve s

pring

compressor. See “Reconditionin

g” in this section

for valve removal instructions

.

3. Pressure test the cylinder head

using the cylinder

head pressure test tools (Tab

le 17).

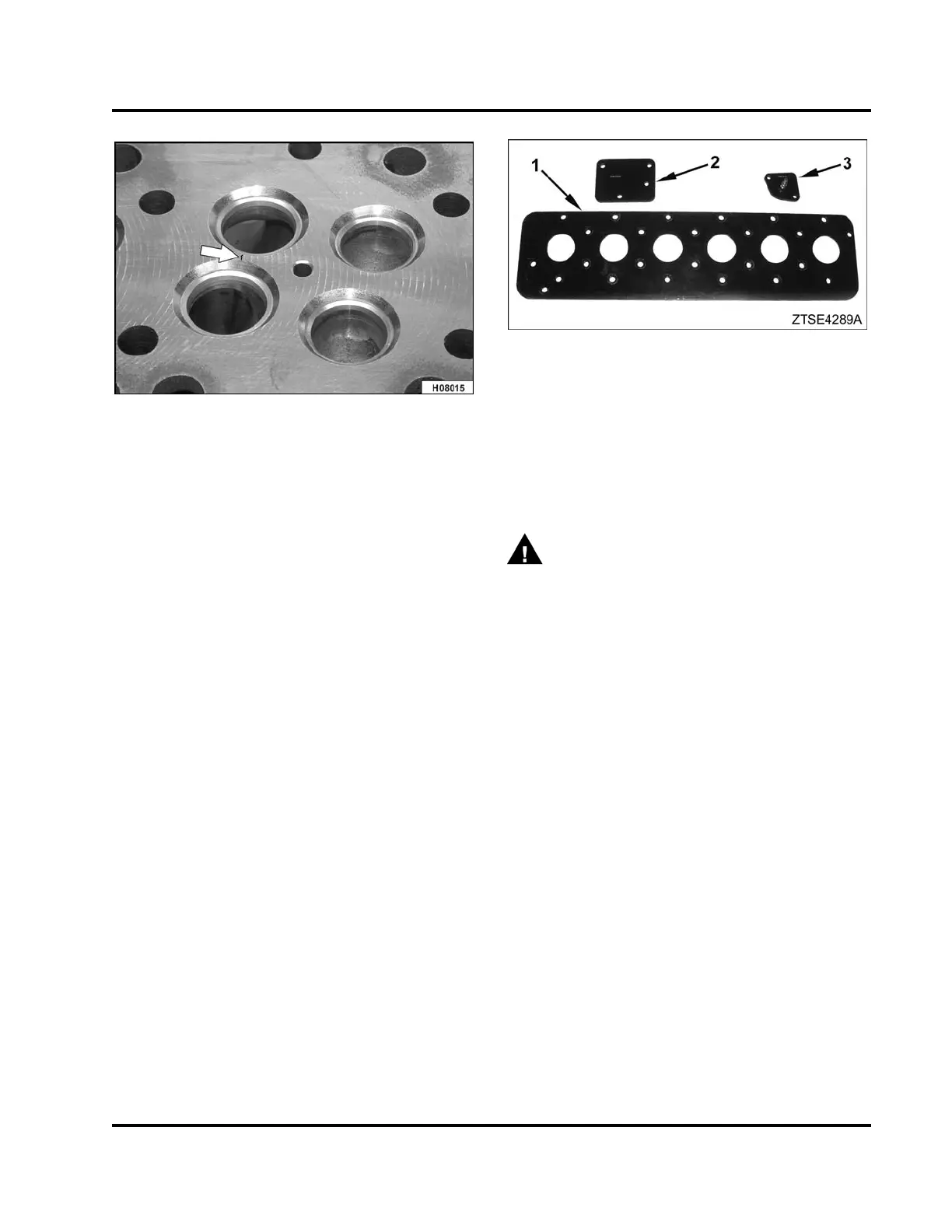

Figure 159 Cylinder head pressure test tools

1. Cylinder head test plate (bolts not shown)

2. Water supply housing pressure adapter

3. Thermostat opening pressure adapter- cylinder head

4. Fasten the pressure plate to the cylinder head

gasket surface using the 24 mounting bolts and

nuts supplied with the kit.

WARNING: To prevent personal injury or

death, wear safety glasses with side shields.

Limit compressed air pressure to 207 kPa (30 psi).

5. Remove thermostat and install air regulator.

Secure to cylinder head with two mounting bolts.

6. Remove the pipe plug next to the thermostat

opening. Fill cylinder head with hot water and

reinstall pipe plug

7. Install a hose fitting to the cylinder head at the

removed plug. Apply 124–138 kPa (18–20 psi)

air pressure and inspect for leaks at the:

• Fuel injector nozzle sleeve area

•Ports

• Upper deck

• Lower deck

If leakage is observed at any port or the upper and

lower deck, replace the cylinder head.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...