242 POWER CYLINDERS

CAUTION: To prevent engine damage, use

permanent marker to identify internal engine

components and their orientation. Do not use paint

or temporary markers.

2. Using a permanent marker, mark each connecting

rod bolt and put another mark on a 15 mm 12 point

socket directly in line with the mark on each rod

bolt.

3. Mark the surface of the connecting rod cap 90°

clockwisefromeachmarkontherodbolt.

4. Align mark on socket with mark on the rod bolt and

install socket on the rod bolt.

5. Torque-to-yield each M11 connecting rod cap bolt

by rotating bolt exactly 90 degrees clockwise (1/4

turn). The mark on the socket and bolt should

be aligned with the mark on the surface of the

connecting rod cap.

Piston Cooling Tubes

Old Piston C ooling Tu bes

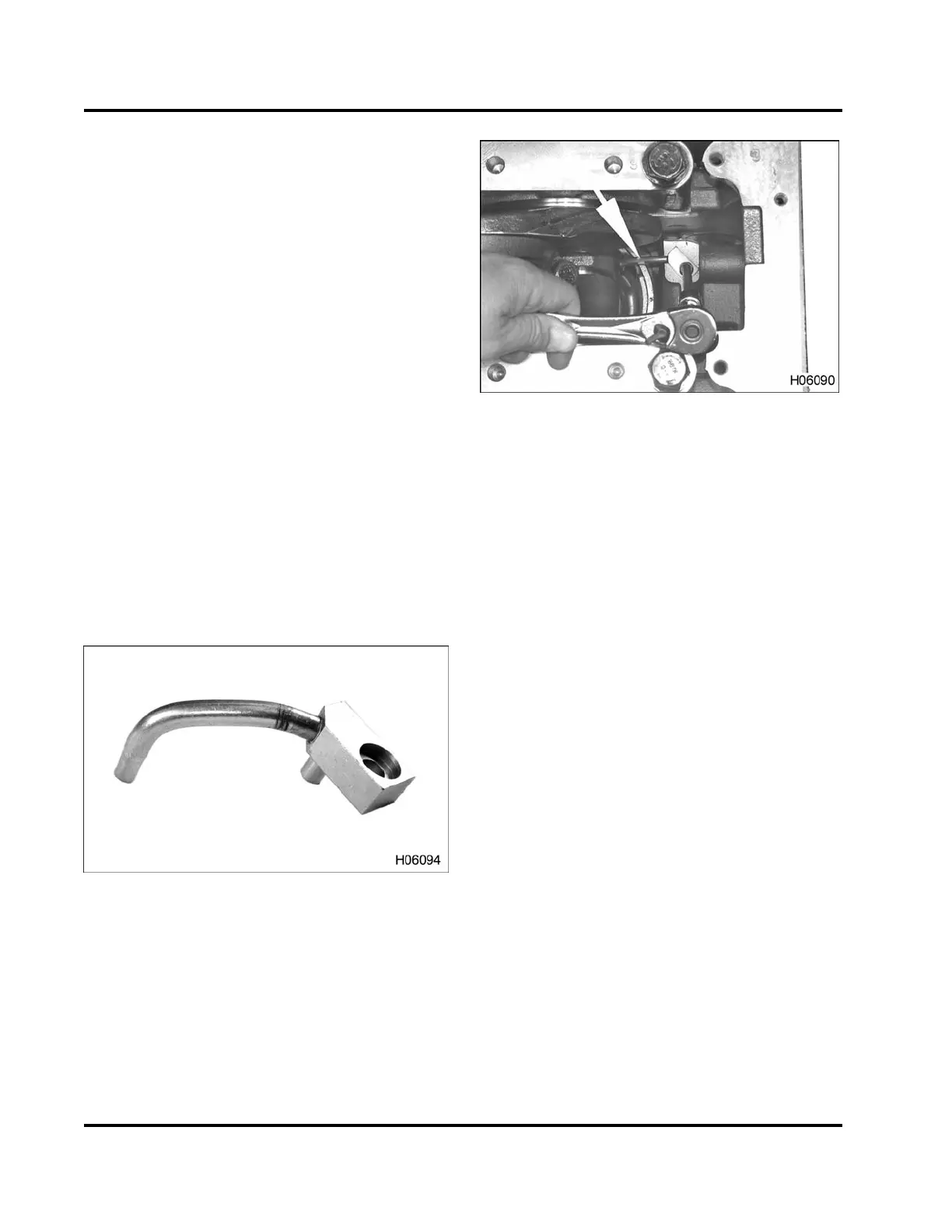

NOTE: The crankshaft may need to be rotated to

access some piston cooling tubes.

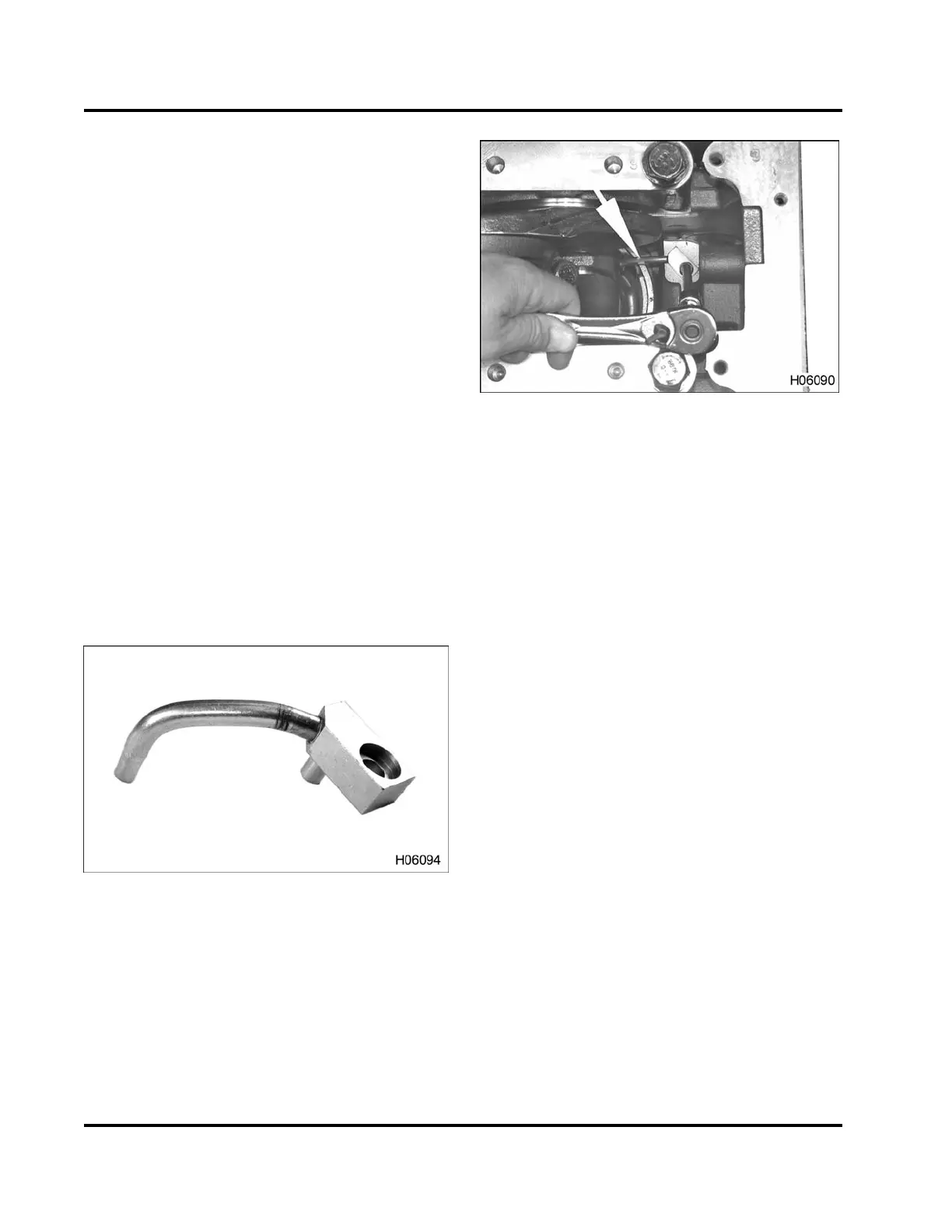

Figure 354 Old piston cooling tube

Figure 355 Old piston cooling tube

CAUTION: To prevent engine damage, the piston

cooling tubes use a special patch type mounting bolt.

Do not substitute.

NOTE: Piston cooling tubes are self aligning.

1. Place piston cooling tubes onto crankcase

mounting pad.

2. When installing the piston cooling tube bolts (M6

x 16), do A or B below:

A. Install new piston cooling tube mounting

bolts (patch type).

B. Remove oil residue, and apply Loctite®

#242 to the threads of existing piston

cooling tube mounting bolts (patch type),

and install M6 x 16 bolts.

3. Tighten M6 x 16 bolts to the special torque value

(Table 33).

New Piston Cooling Tubes

NOTE: The crankshaft may need to be rotated to

access some piston cooling tubes.

CAUTION: To prevent engine damage, the correct

piston cooling tubes must be installed.

NOTE: The non-knurled piston cooling tube is

required for DT 466 engines. The knurled piston

cooling tube is required for DT 570 and HT 570

engines.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...