290 OIL SYSTEM MODULE ASSEMBLY AND SECONDARY FILTRATION

Cleaning and Inspection

Cleaning the Oil System Module

CAUTION: To prevent engine damage, the oil cooler

must be replaced if there was a bearing failure. Debris

from a bearing failure cannot be removed from the oil

cooler.

CAUTION: To prevent engine damage, do not attempt

to clean the assembled oil system module in solvent.

Solvent will be trapped in the oil cooler, regulator valve

assembly, and oil thermal valve assembly. Failure to

follow this caution could result in engine damage.

The following items should be removed:

• Oil cooler

• Regulator valve assembly

• Oil thermal valve assembly

The oil system module housing and lube adapter can

be cleaned in solvent and blown dry with clean filtered

compressed air.

1. Immerse the disassembled oil cooler housing and

lube adapter into a suitable solvent.

WARNING: To prevent personal injury or

death, wear safety glasses with side shiel

ds.

Limit compressed air pressure to 207 k

Pa (30 psi).

2. Flush and drain the oil cooler housing

and

lube adapter to remove any residue. Dr

yall

components with filtered compressed

air.

3. Check the oil cooler housing for bloc

ked orifices

and damaged threads. Replace oil

cooler housing

if required.

4. Remove any debris that may be bloc

king the filter

bypass valve.

5. Remove turbocharger oil supply fi

tting (M18) on

top of oil filter header and disca

rd O-ring seal.

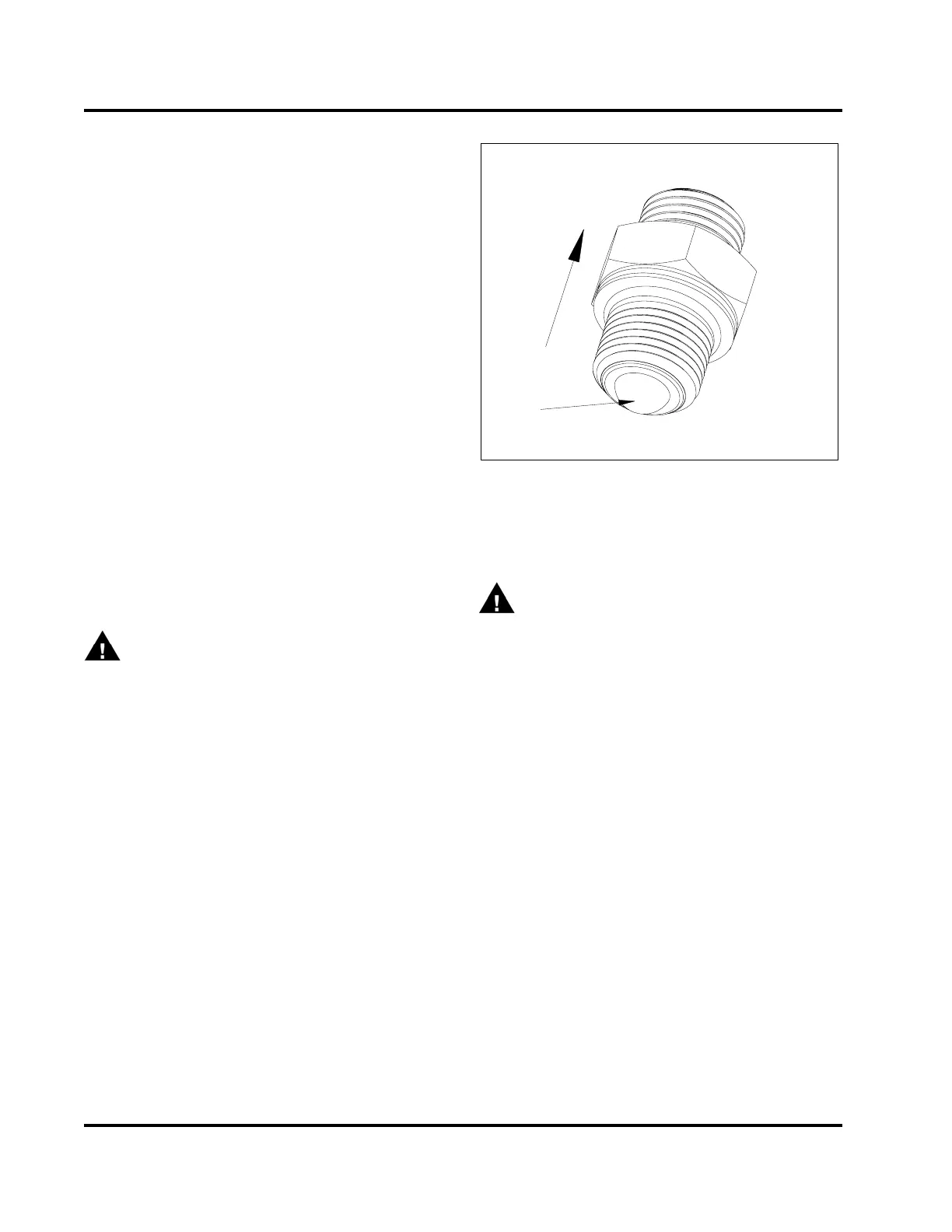

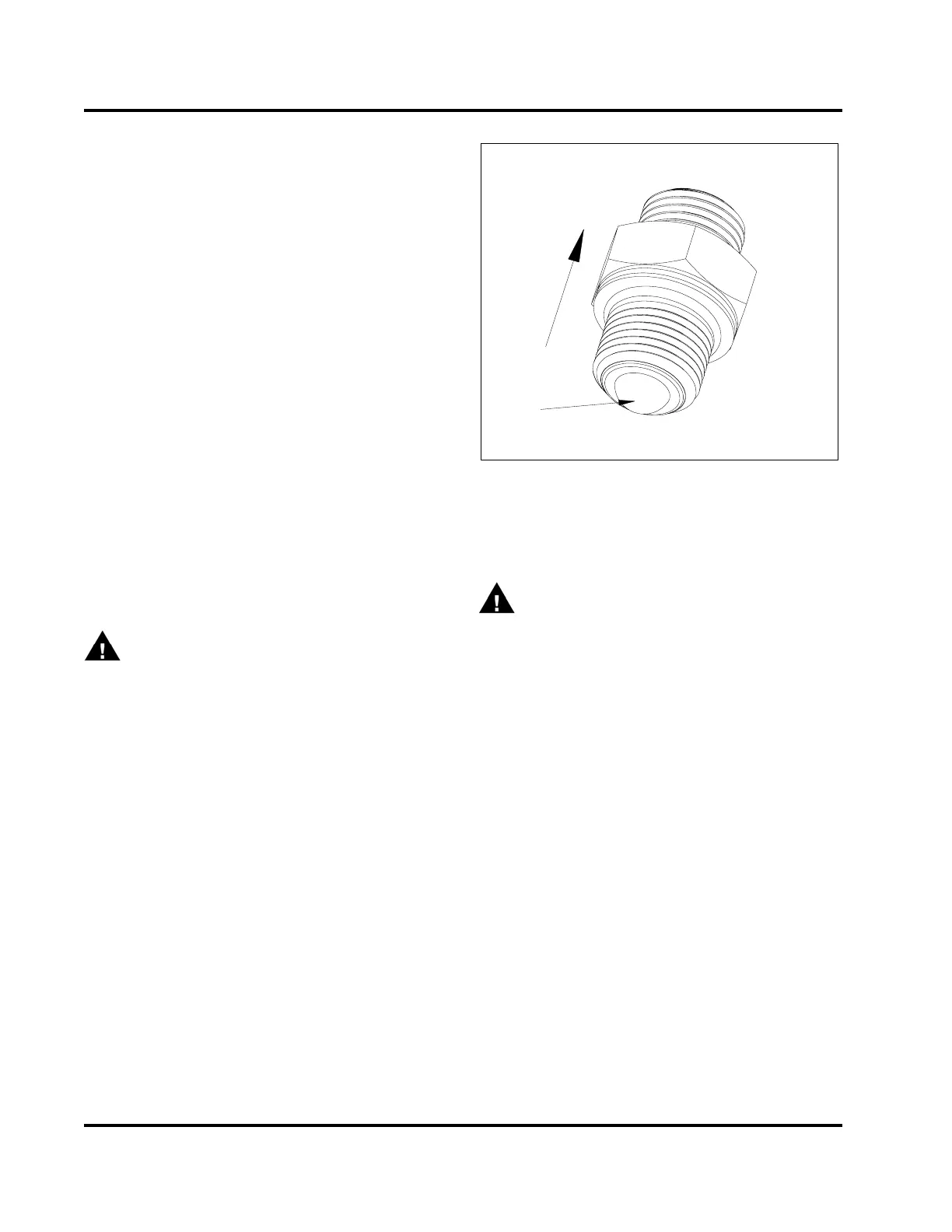

1

H13031

2

Figure 422 Oil supply tube fitting

1. Direction of oil flow

2. Oil supply wire mesh screen

WARNING: To prevent personal injury or

death, wear safety glasses with side shields.

Limit compressed air pressure to 207 kPa (30 psi).

6. Inspect screen for damage or particle obstruction.

Clean or replace oil supply tube fitting screen as

necessary.

7. Install a new O-ring onto fitting and thread into oil

filter header. Tighten to the special torque value

(Table 42).

Checking the Cooler Heat Exchanger for Leakage

External

CAUTION: To prevent engine damage, do not allow

water to enter oil side of cooler heat exchanger

assembly.

1. Remove the eight bolts (M8 x 20) securing cooler

heat exchanger to the oil system module, if not

done so already.

2. Fasten Oil Cooler Test Plate (Table 43) to cooler

heat exchanger.

3. Make sure oil port valve is closed.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...