228 POWER CYLINDERS

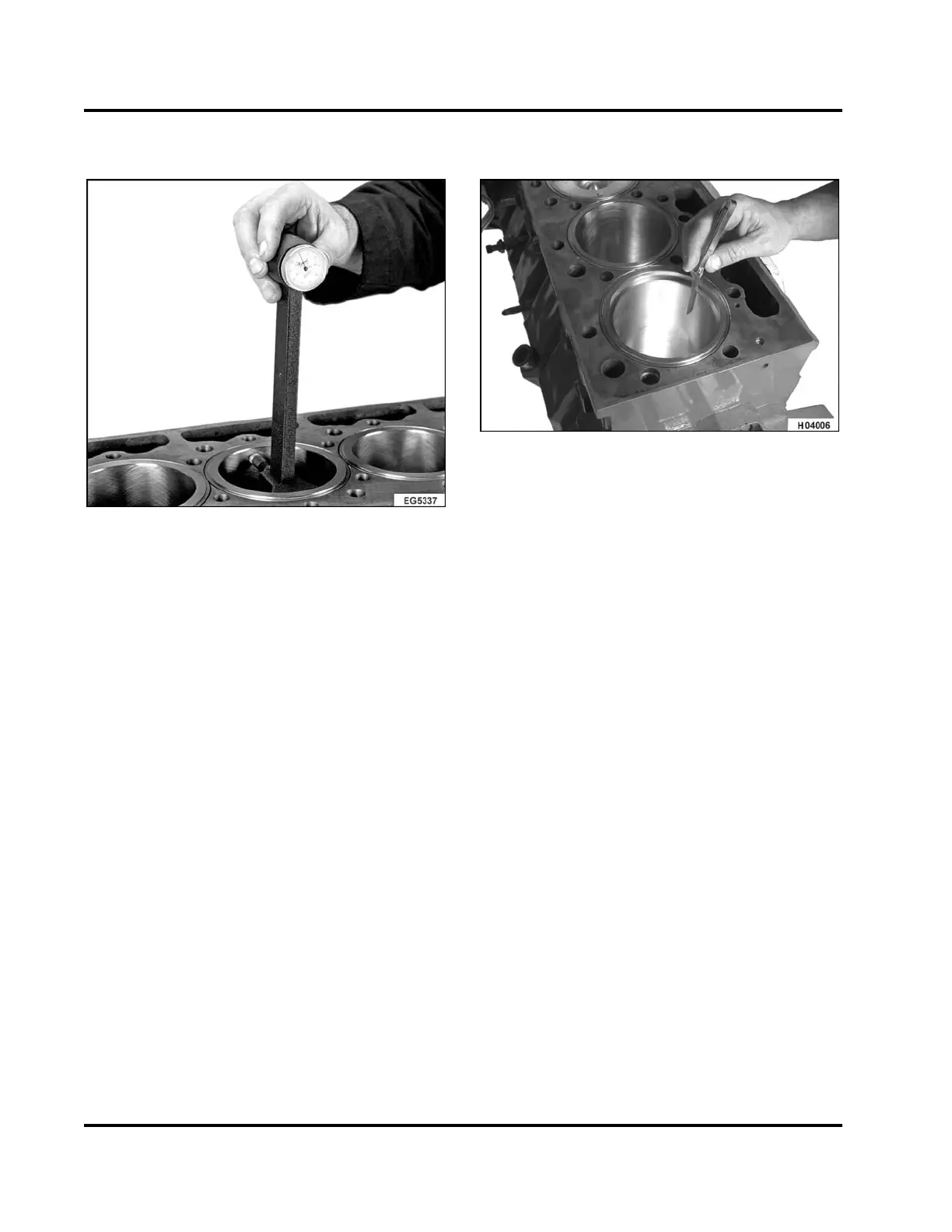

Dial Bore Gauge Method

Figure 323 Checking cylinder sleeve inside

diameter with dial bore gauge

a. Use a dial bore gauge to measure the

inside diameter of the each cylinder

sleeveatthetopofpistonringtravel

and below the area of piston ring travel.

Record the readings.

b. Subtract the lower reading from the

higher reading. The result is the cylinder

sleeve taper.

If the result exceeds the specification,

replace the cylinder sleeve.

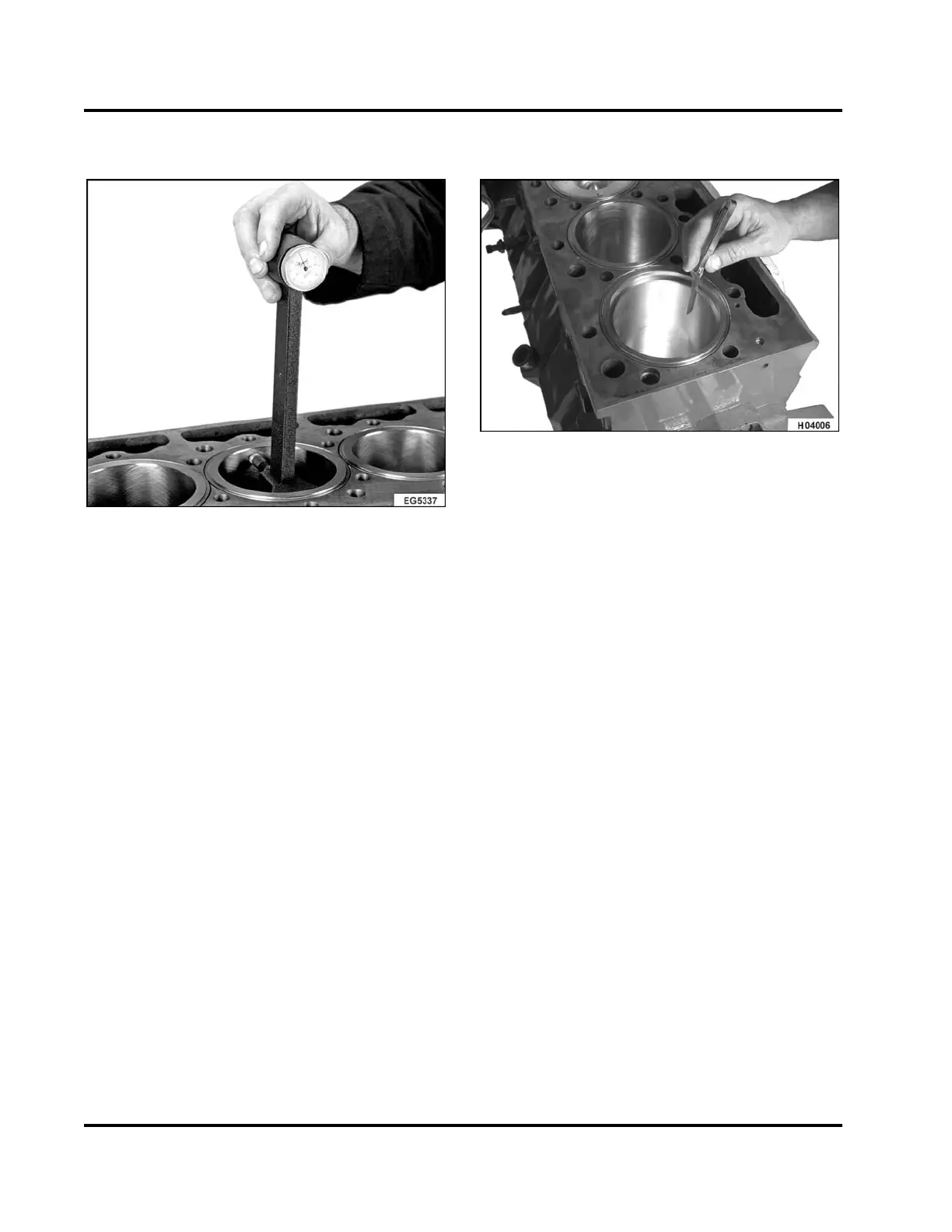

Feeler Gauge Method

Figure 324 Checking cylin der sle eve pist on ring

end gap

a. Install a top compression ring squarely

above the top of the piston ring travel

area. Use a feeler gauge to measure

the piston ring end gap. Record the

measurement.

b. Movethetopcompressionringsquarely

below the bottom of the piston ring travel

area. Use a feeler gauge to measure

the piston ring end gap. Record the

measurement.

Every increase of 0.07 mm (0.003 in)

between the measurements equals a

0.025 mm (0.001 in) increase in cylinder

sleeve inside diameter. If the cylinder

sleeve is worn beyond the specification,

replace the cylinder sleeve.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...