ENGINE SYSTEMS 31

beneath the plunger. The needle control spring holds

the needle onto its seat to prevent fuel from entering

the combustion chamber.

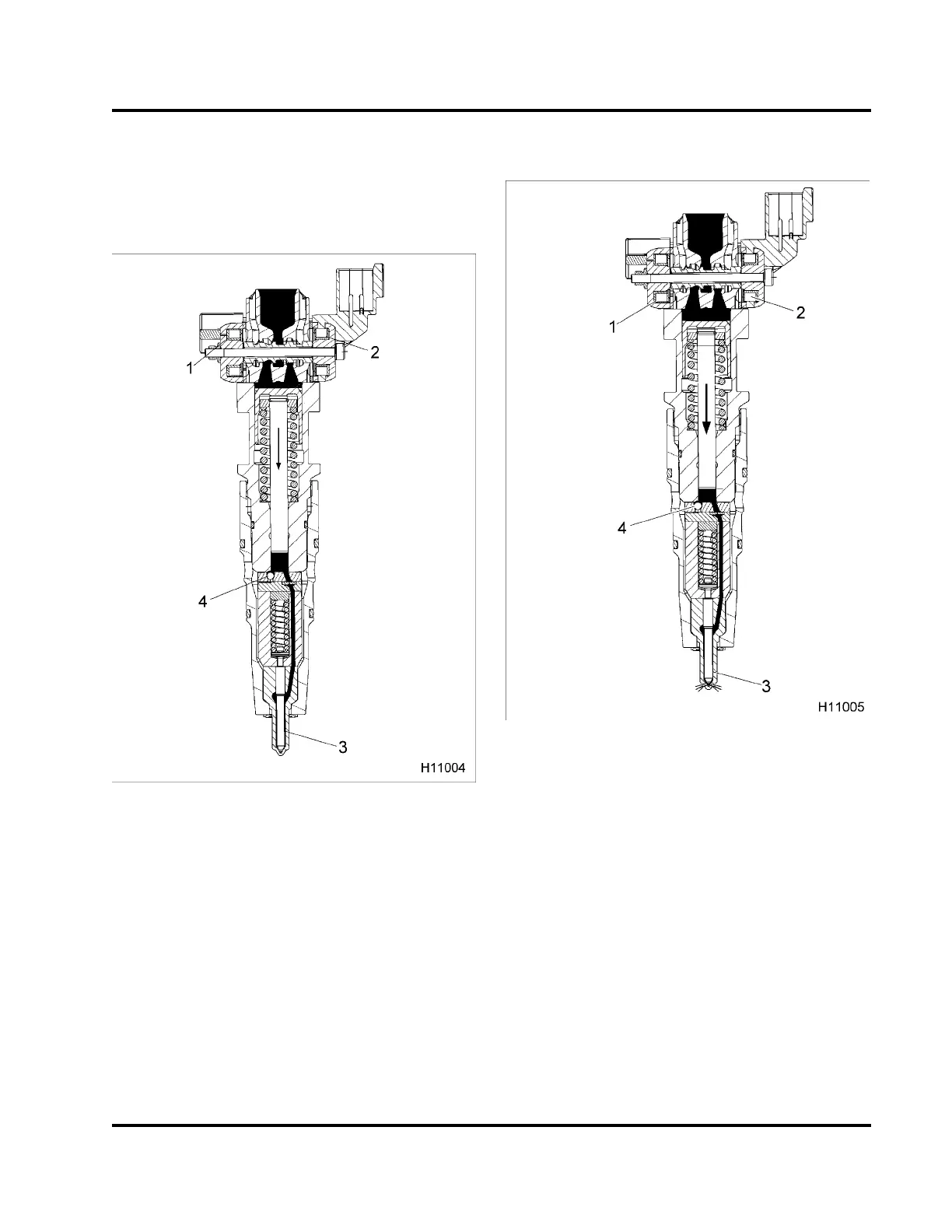

Main inject ion (Step 1 )

Figure 25 Main injection (Step 1)

1. CLOSE coil (off)

2. OPEN coil (on)

3. Needle (seated)

4. Fuel inlet check ball (seated)

A pulse width current energizes the OPEN coil.

Magnetic force moves the spool valve open.

High-pressure oil flows past the spool valve and

onto the top of the intensifier piston. Oil pressure

overcomes the force of the intensifier piston spring

and the intensifier starts to move down. An increase

in fuel pressure under the plunger seats the fuel inlet

check ball, and fuel pressure starts to build on the

needle.

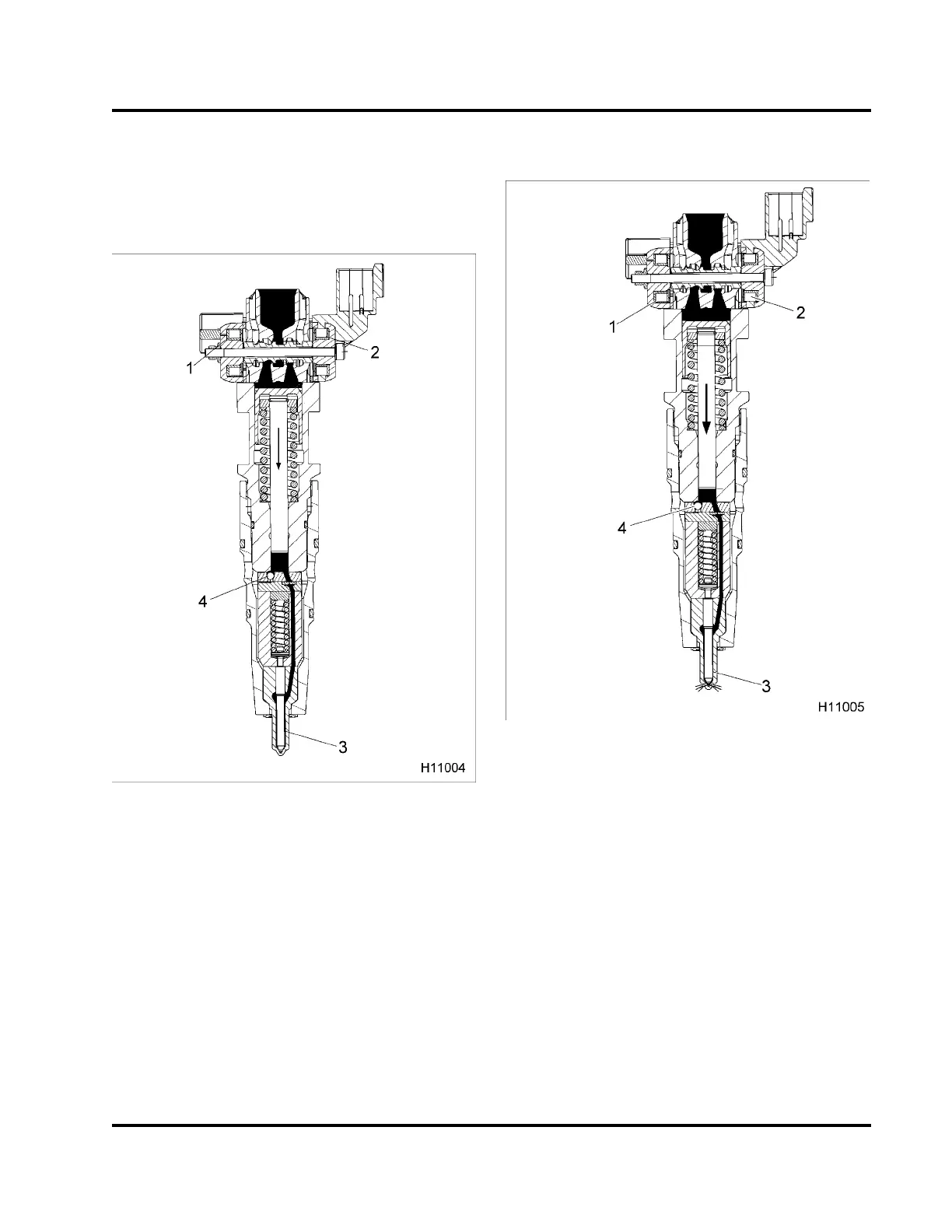

Main injection (Step 2)

Figure 26 Main injection (Step 2)

1. CLOSE coil (off)

2. OPEN coil (off)

3. Needle (unseated – VOP)

4. Fuel inlet check ball (seated)

The pulse-width controlled current to the OPEN coil

is shut off, but the spool valve remains open. High

pressure oil from high pressure oil rail continues to

flow past the spool valve. The intensifier piston and

plunger continue to move and fuel pressure increases

in the barrel. When fuel pressure rises above the VOP

- about 28 MPa (4,075 psi) - the needle lifts of its seat

and injection begins.

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...