APPENDIX B – TORQUES 445

General Torque Guidelines

CAUTION: To prevent engine damage, do not

substitute fasteners. Original equipment standard

hardware is defined as Class 10.9 metric or Grade 8

standard coarse thread bolts (Rockwell "C" 33-39),

all phosphate coated.

CAUTION: To prevent engine damage, do not use this

standard torque chart with other International brand

engines or engines made by other manufacturers.

The standard torque chart provides the tightening

values for general purpose applications using original

equipment standard hardware as listed in the Parts

Catalog for the application involved.

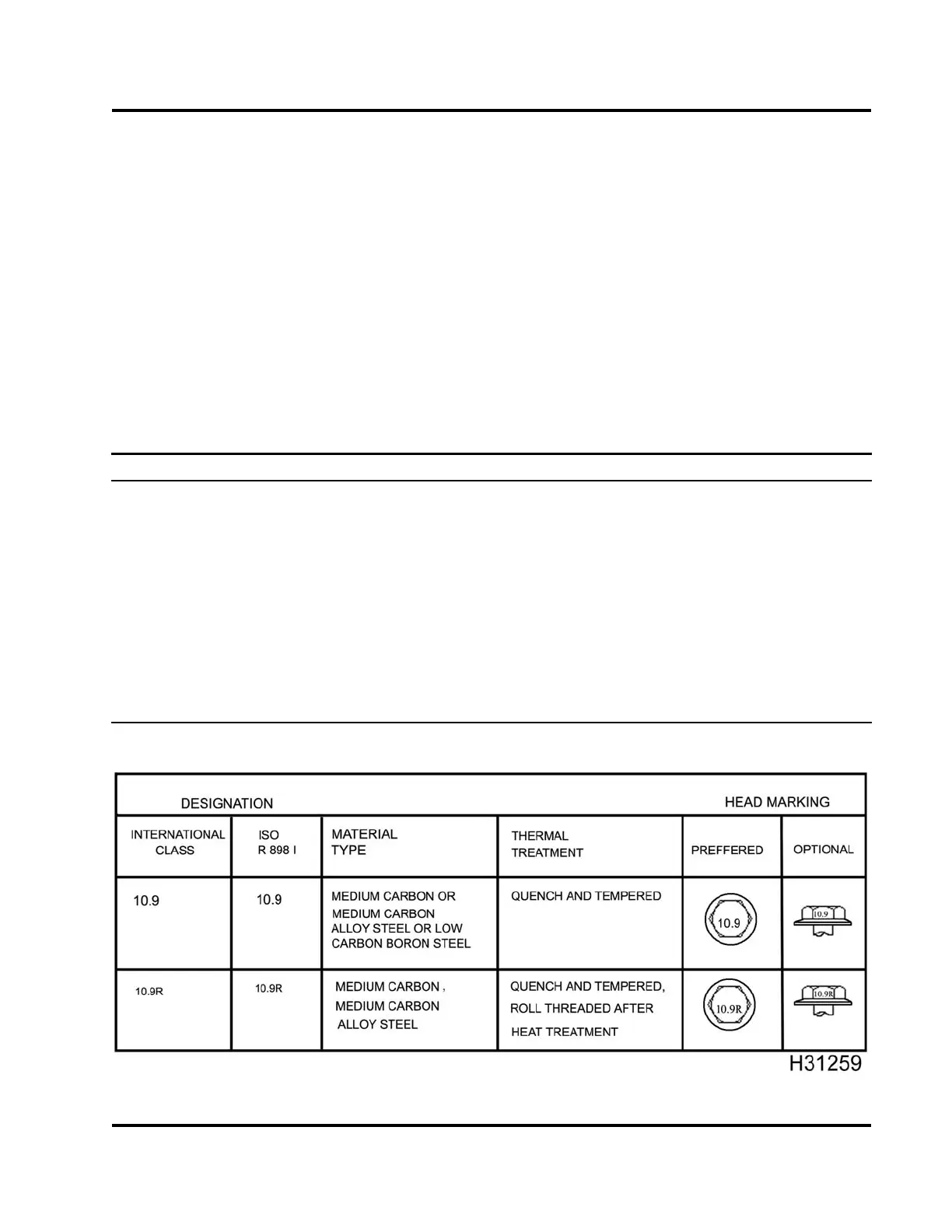

Table 76 S tandard Torque Values – Class 10.9 Metric Flange Head Bolts and Studs

Thread Diameter (mm) Thread Pitch (mm)

Torque

1

61

13 N·m (115 lbf·in)

81.25

31 N·m (23 lbf·ft)

10 1.5

62 N·m (45 lbf·ft)

12 1.75

107 N·m (79 lbf·ft)

14 2

172 N·m (127 lbf·ft)

15 2

216 N·m (159 lbf·ft)

16 2

266 N·m (196 lbf·ft)

18 2.5

368 N·m (272 lbf·ft)

20 2.5

520 N·m (384 lbf·ft)

1

Values listed are 80% of proof load.

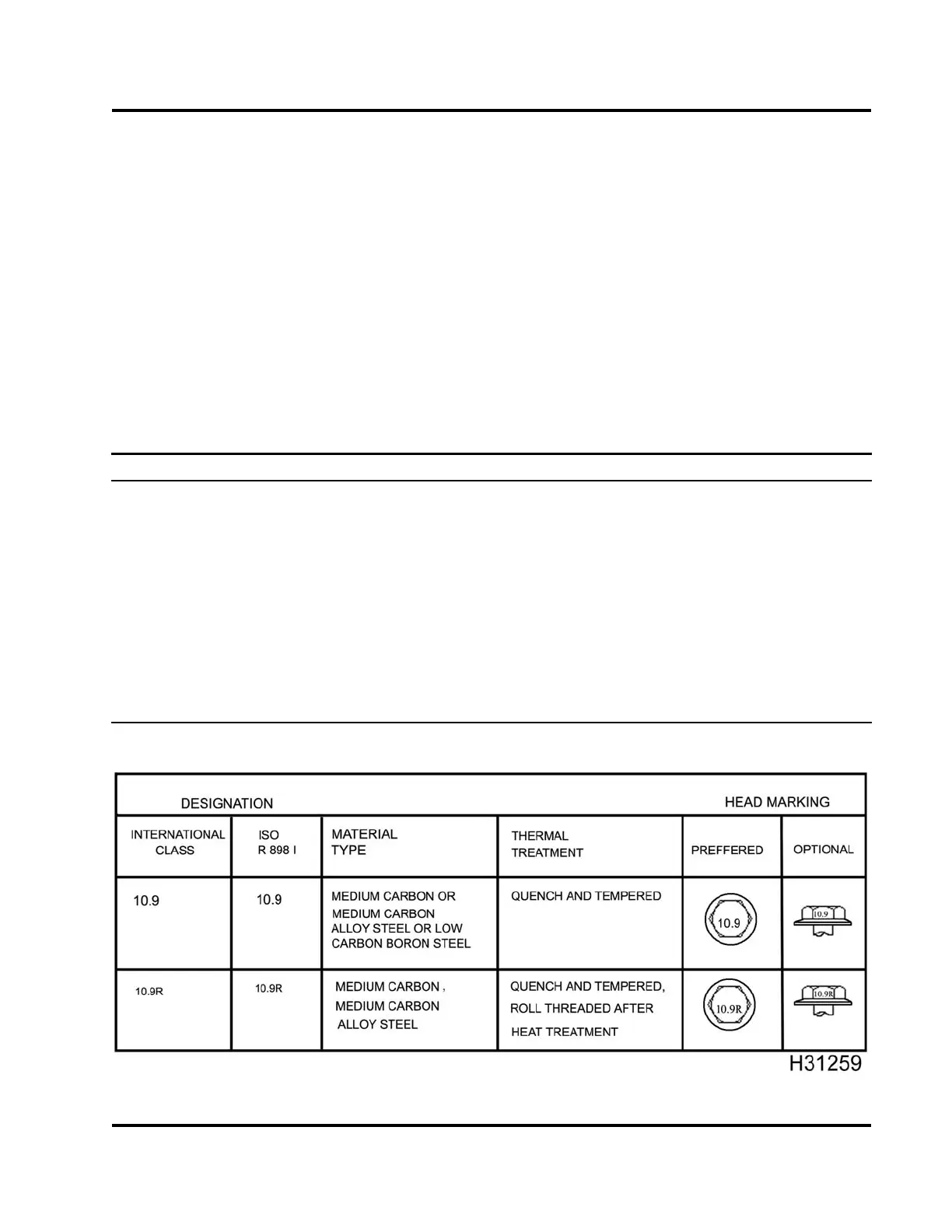

Figure 655 Classification and Identification – Metric and Special Use Fasteners

EGES-265-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© 2009 Navistar, Inc.

Loading...

Loading...