WEILER E2850 REMIXING TRANSFER VEHICLE

5-21

Maintenance

5

Maintenance Procedures

Discharge Conveyor Chain Tension - Check/Adjust Uneven Sag

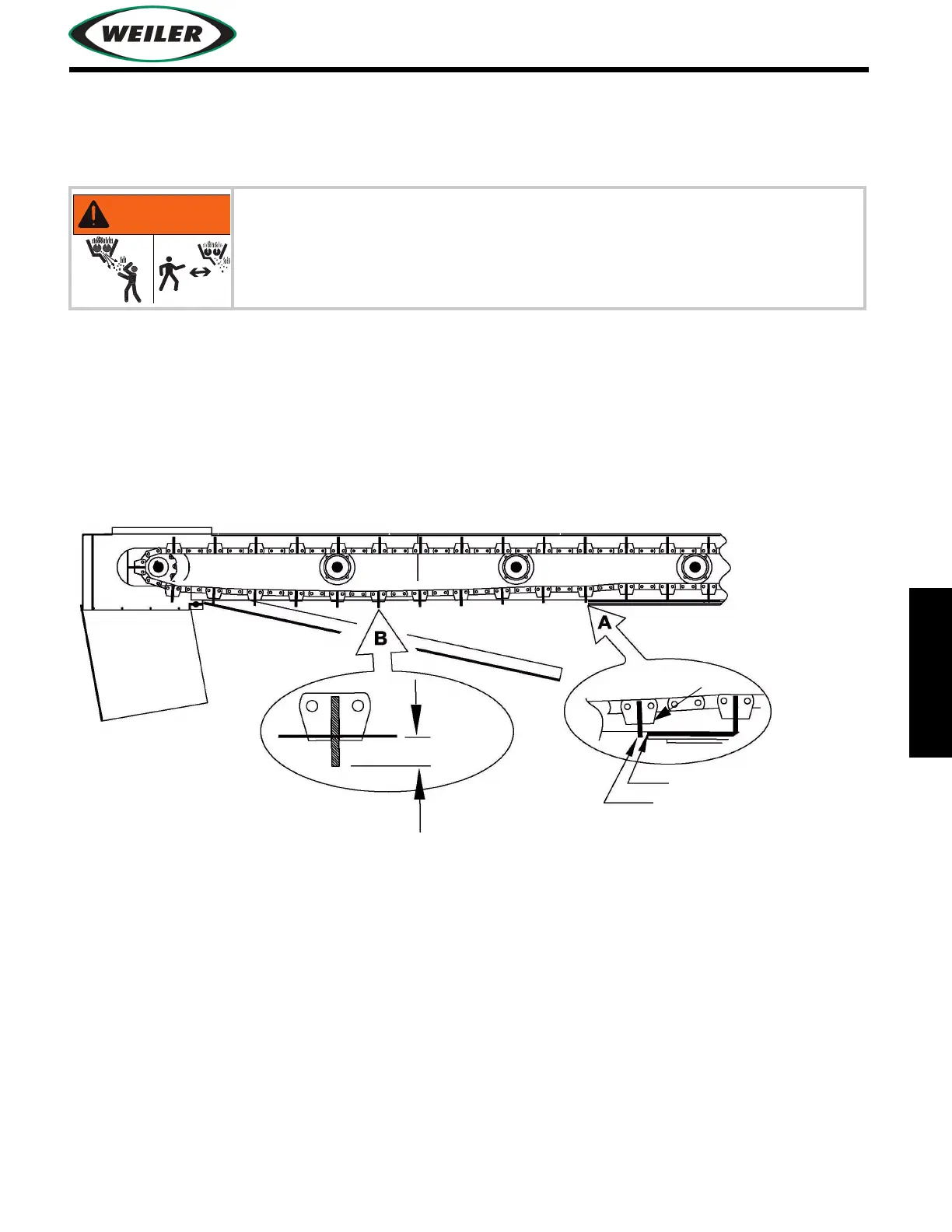

Discharge conveyor chain is automatically tensioned. Check chain sag monthly or every 150 service

hours to verify proper function of tensioner. Inspect chain for wear. Maintain chain sag at 4-9"

(102-229 mm) at measurement point shown in detail view B.

1. Start engine and run 2-3 minutes. Open discharge conveyor cleanout door. Refer to

"Discharge

Conveyor Cleanout", page 3-55.

2. Lower conveyor. Run conveyor chain for 2-3 minutes.

3. Run chain forward until a chain slat is just off edge of floor plate as shown in detail view A.

4. Bump chain forward/reverse until chain sag is no longer increasing. The final chain bump must

be in reverse for maximum chain sag to occur. Do not allow a chain slat to ride up onto floor

plate.

5. Turn engine off and remove ignition key.

6. At midpoint of cleanout door, measure chain sag from bottom of frame flange to bottom of slat as

shown in detail view B. Measure both sides of chain to ensure chain sag is even from side to side,

+/- 1/4" (6 mm).

• If chain sag is out of range, manually run an auto-adjust tensioning cycle. Refer to

"Manually

Starting an Auto-Adjust Cycle"

, page 5-16.

• If chain sags unevenly from left to right, refer to

"Discharge Conveyor Chain - Adjust Uneven

Sag", page 5-22.

Contact a Weiler dealer if chain sag remains out of range or uneven after adjustment.

7. Check chain for wear. Refer to

"Chain Checklist", page 5-22. Contact a Weiler dealer if chain

shows significant wear or stretch.

Contact with hot asphalt can cause severe burns.

Stay clear when opening cleanout door.

4–9" (102–229 mm)

chain side bar

Chain slat just off

edge of floor pan

and not catching on

hi id b

Chain slat just off edge

of floor plate and not

catching on chain side bar

Edge of floor plate

Loading...

Loading...