WEILER E2850 REMIXING TRANSFER VEHICLE

5-55

Maintenance

5

Maintenance Procedures

Sprockets - Elevator/Discharge Conveyor - Inspect

Check sprockets for:

•Hooked Teeth - Worn teeth will over-stress chain and cause chain to snap in and out of

sprocket and possibly hang up when exiting.

•Build-Up in Pockets - Material packed in the pockets will cause chain to stretch.

•Teeth Scrubbed On Sides - Indicates misalignment of sprockets and shafts. Chain could also

be worn to the point it won’t track properly.

•Chain Rides High On Teeth - Chain is elongated and close to needing replacement.

•Chain Too Tight - Indicates material packed in pockets or chain over-tensioned.

•Noise - Chain should make a clicking sound (metal on metal) as it engages the sprocket. If it is

snapping or popping, check for hooked teeth or stretched chain.

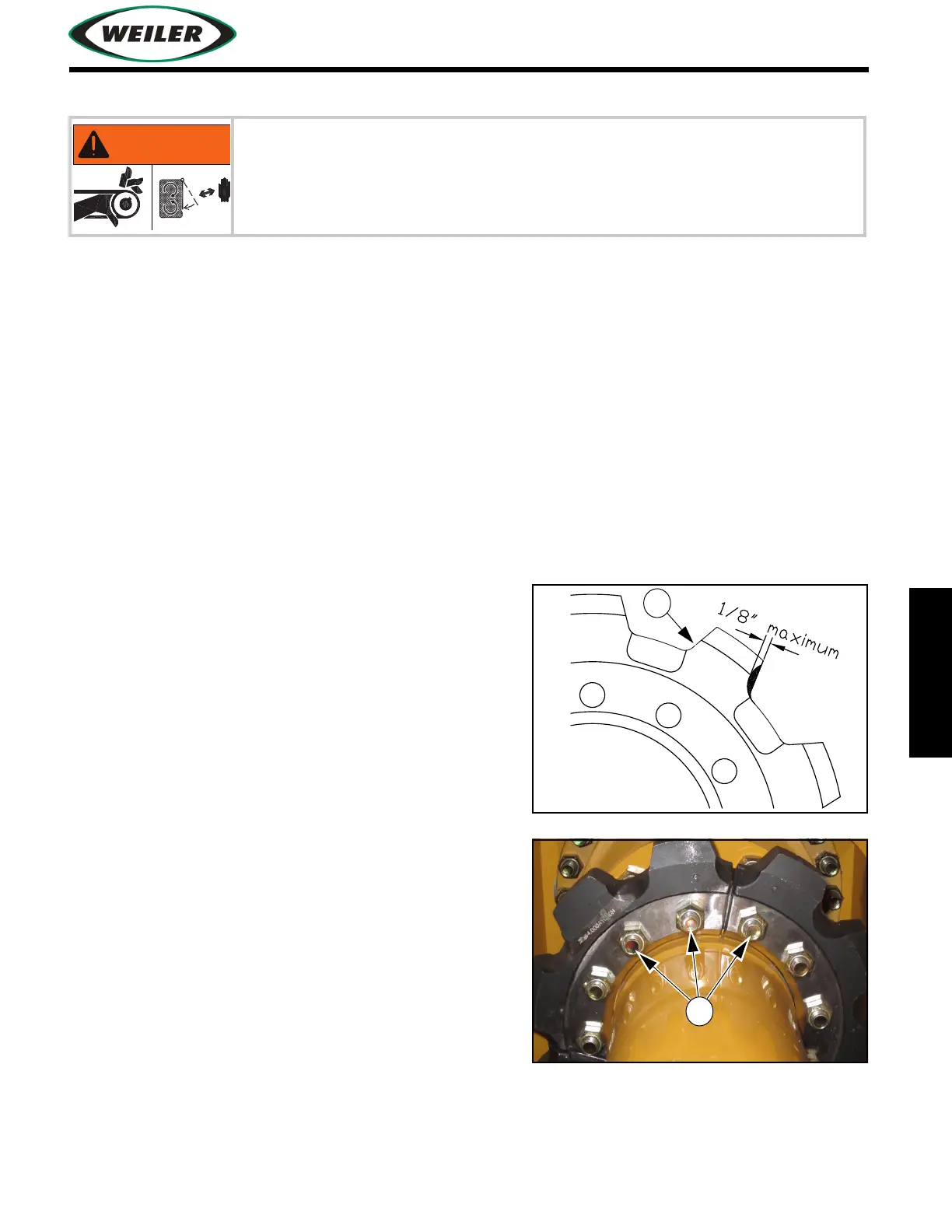

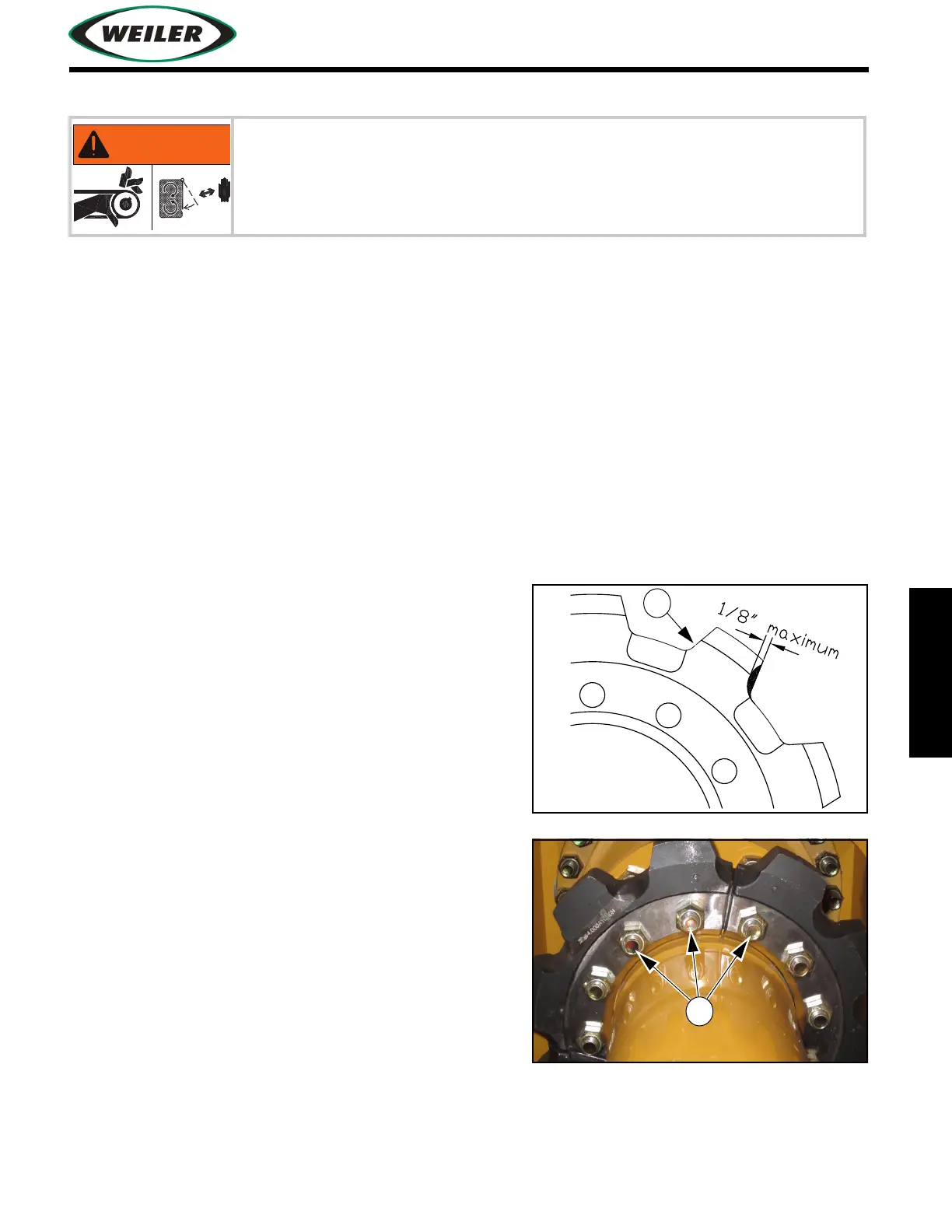

1. Inspect sprocket teeth (1) for wear.

NOTICE: Replace both sprockets as a pair when wear

exceeds 0.13" (3 mm). Failure to replace excessively worn

sprockets may result in premature chain wear or

damage. If chain is worn, replace chain to prevent

premature wear of new sprockets.

2. Check for loose or missing sprocket mounting bolts

(2). Tighten or replace any loose or missing bolts.

Contact with moving conveyor belt and rollers can crush or cut.

Stay away from moving conveyor. Turn conveyor and engine off before

inspecting, adjusting, cleaning, unplugging, or servicing conveyor.

Loading...

Loading...