4.7 Auto-Tuning

YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual 121

Start-Up Programming

& Operation

4

Auto-Tuning for Permanent Magnet Motors

Automatically sets the V/f pattern and motor parameters E1- and E5- when a PM motor is used. In Closed Loop

Vector Control, the Auto-Tuning process will also set some F1- parameters for speed feed

back detection.

Table 4.23 Types of Auto-Tuning for Permanent Magnet Motors

Table 4.24 lists the data that must be entered for Auto-Tuning. Make sure the data is available before starting

Auto-Tuning.

The information needed is usually listed on

the motor nameplate or in the motor test report provided by the motor

manufacturer. Also refer to Subchart A-3: Operation with Permanent M

agnet Motors on page 112 for details on the

tuning mode selection and

the tuning process.

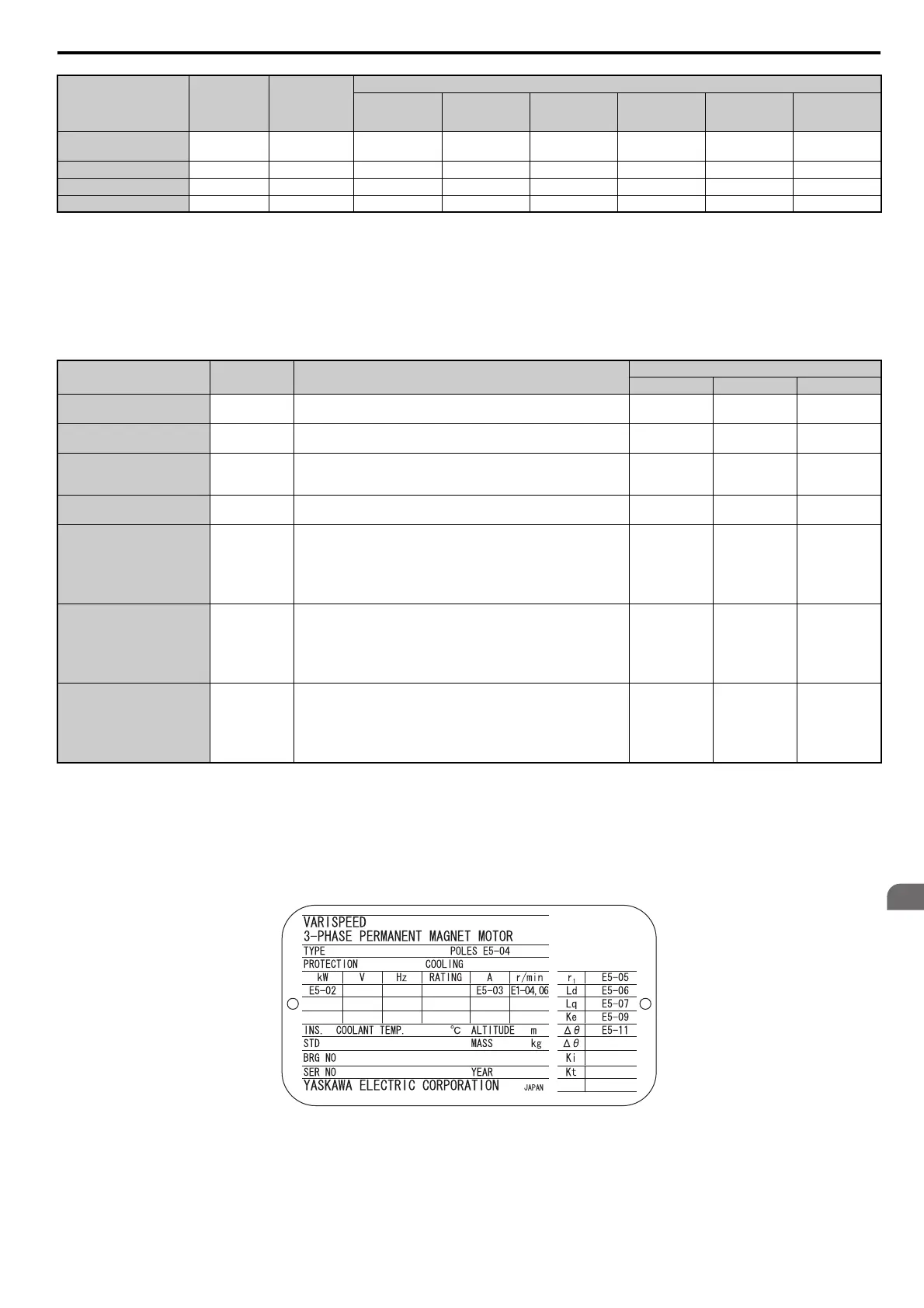

Figure 4.15

Figure 4.16 Example of Motor Nameplate

PG Number of pulses per

revolution

T1-08 – YES

<1> YES <1> N/A N/A YES <1> YES <1>

Motor no-load current T1-09 A N/A YES N/A N/A YES YES

Motor rated Slip T1-10 Hz N/A N/A N/A N/A YES N/A

Motor iron loss T1-11 W N/A N/A N/A YES N/A N/A

<1> Input data is needed for CLV/PM only.

Type Setting Application Conditions and Benefits

Control Mode

OLV/PM AOLV/PM CLV/PM

PM Motor Parameter Settings

T2-01 = 0

• Motor does not rotate during Auto-Tuning

• Motor test report or motor data like listed in Tab le 4.24 are available.

YES YES

YES

PM Stationary Auto-Tuning

T2-01 = 1

• A motor test report listing motor data is

not available. Drive

automatically calculates and sets motor parameters.

YES YES

YES

PM Stationary Auto-Tuning for

Stator Resistance

T2-01 = 2

• Useful to tune the drive when the mot

or data were set up manually or by

motor code and the cable is longer than 50 m. Should also be performed if

the cable has changed after earlier tuning.

YES YES

YES

Z Pulse Offset Tuning

T2-01 = 3

• PG encoder has been replaced. Calculates the Z pulse offset.

• Requires the motor to rotate with no or very low load.

N/A N/A

YES

Back EMF Constant Tuning T2-01 = 11

• Use if a motor test is not available.

• Tunes the motor induction voltage only.

• Should be performed after motor data a

re set and the encoder offset is

adjusted.

• The motor must be uncoupled from t

he mechanical system (remove

loads).

N/A N/A

YES

High Frequency Injection

Parameter Tuning

T2-01 = 13

• The motor rotated in reverse or STo fault

(Motor Step-Out) occurred at

startup in OLV/PM

• Low speed and insufficient or no torque after activating the high

frequency i

njection control (n8-57 = 1) in AOLV/PM.

• Faults, such as the motor rotating in revers

e, occurred when the power

was turned on during initial startup in CLV/PM.

N/A YES

YES

PM Rotational Auto-Tuning T2-01 = 14

• A motor test report listing motor data is not available.

• Motor can be decoupled from the l

oad and rotate freely while

Auto-Tuning is performed. Drive automatically calculates and sets motor

parameters.

• PM Rotational Auto-Tuning gives more ac

curate results than Stationary

Auto-Tuning.

YES YES YES

Input Value

Input

Parameter

Unit

Tuning Type (T1-01)

0

Standard

1

Stationary 1

2

Line-to-Line

Resistance

3

Rotational for

V/f Control

4

Stationary 2

5

Stationary 3

'5,9( 233

(1'

(1'

667

(

6L

Loading...

Loading...