5.4 d: Reference Settings

YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual 207

Setting the Torque Reference, Speed Limit, and Torque Compensation Values

Torque Control Reference Sources

Input values for Torque Control can be set like explained in Table 5.19.

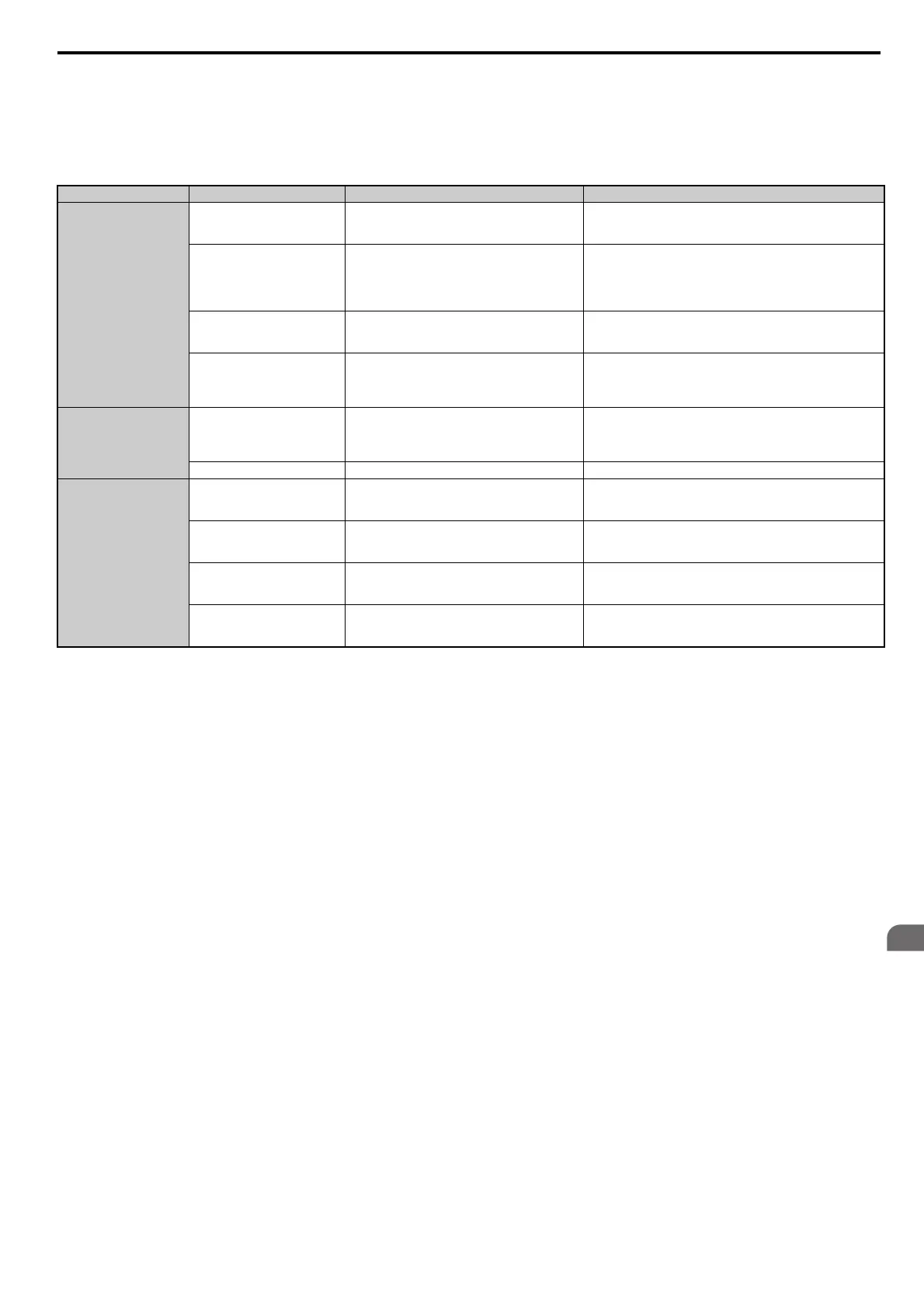

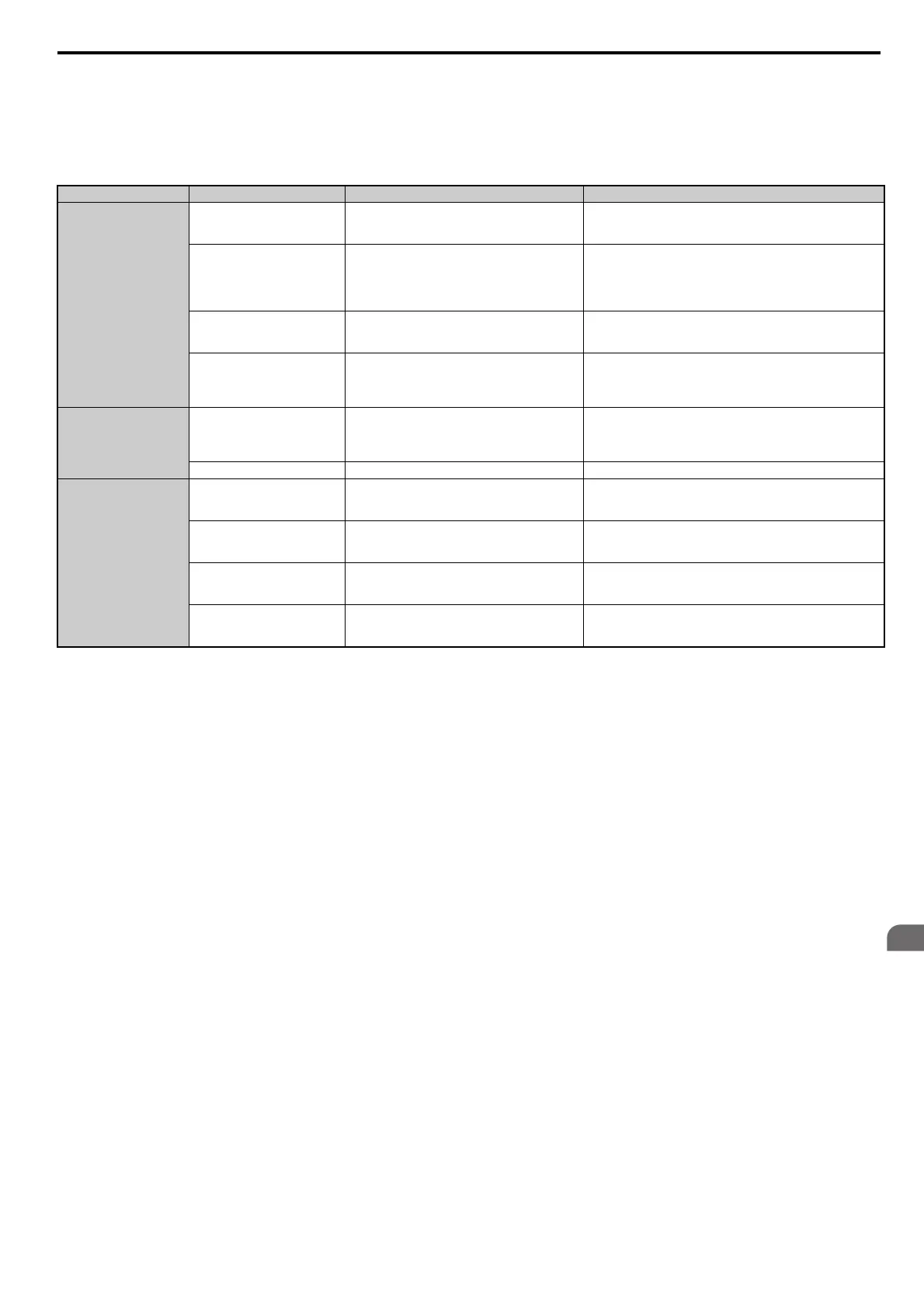

Table 5.19 Torque Control Input Value Selection

Input Value Polarity

The direction of the input values described above depends on the polarity of the Run command and the input value.

• With a Forward run command and a positive torque reference

signal the internal torque reference will be positive, i.e.,

in the forward direction.

• With a Forward run command and a negative torque reference signal the internal torque reference will be negative, i.e.,

in the reverse direction.

When analog inputs are used, negative input

values can be generated by

• applying negative voltage input signals.

• using positive analog input signals but setting the analog input bias

to negative values so that the input value can be

negative.

• applying positive voltage input signals and using a digital i

nput that is programmed for H1- = 78.

When MEMOBUS/Modbus communication or a communicati

on option card is used, only positive input values can be

set.

Input Value

<1> Sets analog input terminals A1, A2, and A3 to supply the speed limit, torque reference, or torque compensation. An oPE07 error

(Multi-Function Analog Input Selection Error) will occur if two analog inputs are set for the same function.

Signal Source Settings Remarks

Torque Reference

Analog inputs A1/A2/A3 H3-02, H3-10, or H3-06 = 13 <1>

Make sure the signal level settings for the input terminal selected

match the signal used. Refer to H3: Multi-Function Analog Inputs

on page 257 for details on adjusting analog input signals.

Analog Option Card

• F2-01 = 0

• H3-02, H3-10, or H3-06 = 13

<1>

The H3- settings become effective for the option board input

terminals. Make sure the signal level settings for the input terminal

selected match the signal used. Refer to H3: Multi-Function

Analog Inputs on page 257 for details on adjusting analog input

signals.

MEMOBUS Register 0004H

• b1-01 = 2

• Set Register 000FH, Bit 2 = 1 to enable Torque

reference f

rom register 0004H

–

Communication Option Card

• b1-01 = 3

• F6-06 = 1

Refer to the option card manual for details about

se

tting the torque reference.

–

Speed Limit

Signal selected as frequency

reference source

d5-03 = 1

The speed limit is taken from the input selected as

frequency reference source in parameter b1-01 or

b1-15.

<1>

The settings in C1- for accel/decel times and in C2- for

S-curves are applied to the speed limit value.

Parameter d5-04 d5-03 = 2

–

Torque Compensation

Analog inputs A1/A2/A3 H3-02, H3-10, or H3-06 = 14

<1>

Make sure the signal level settings for the input terminal selected

match the signal used. Refer to H3: Multi-Function Analog Inputs

on page 257 for details on adjusting analog input signals.

Analog Option Card

• F2-01 = 0

• H3-02, H3-10, or H3-06 = 14

<1>

The H3- settings become effective for the option card input

terminals. Make sure the signal level settings for the input terminal

selected match the signal used.

MEMOBUS Register 0005H

• b1-01 = 2

• Set Register 000FH, bit 3 = 1 to enable the torque

com

pensation setting by register 0005H

–

Communication Option Card

• b1-01 = 3

• Refer to the option card manu

al for details about

setting the torque compensation value.

–

Loading...

Loading...