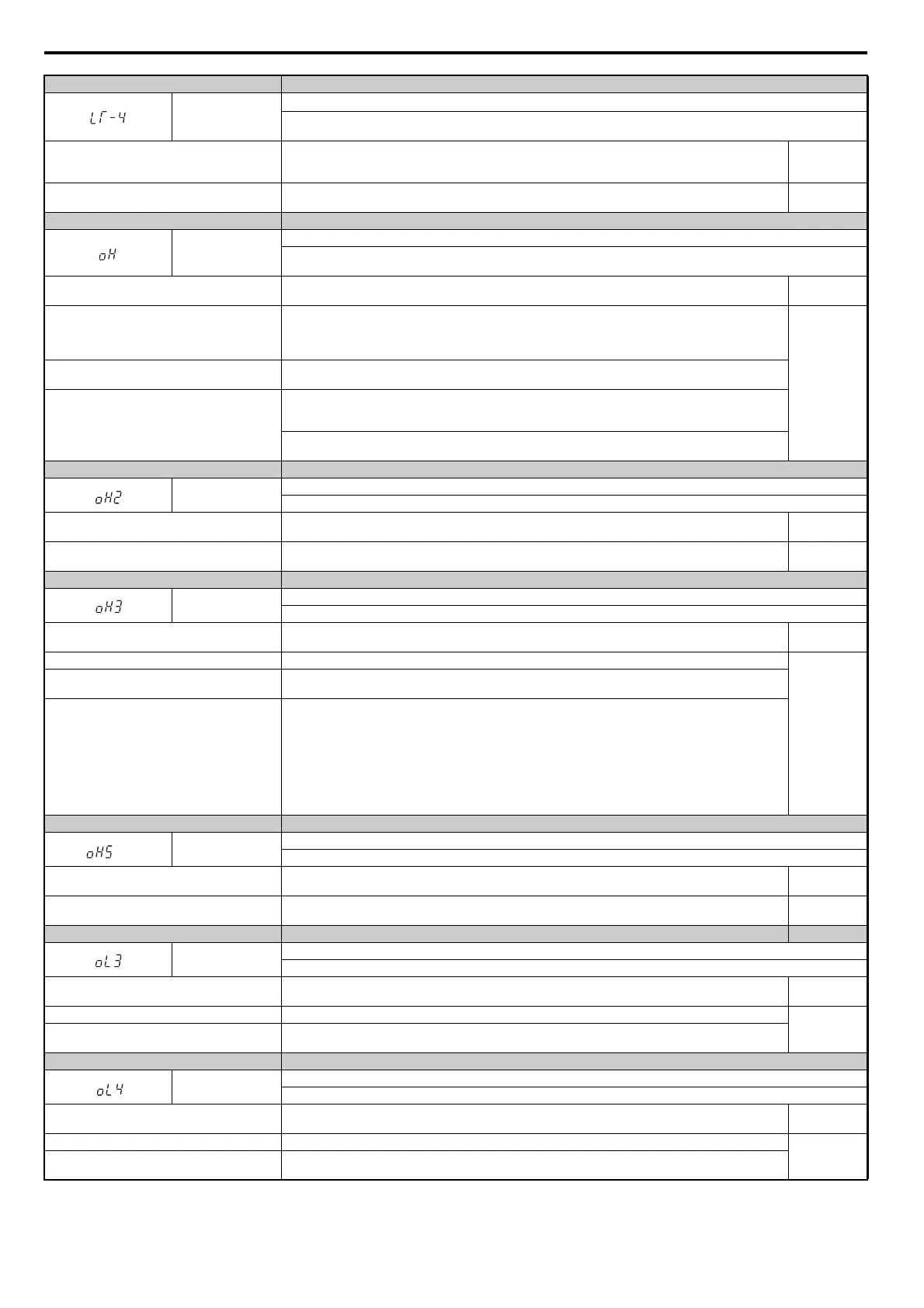

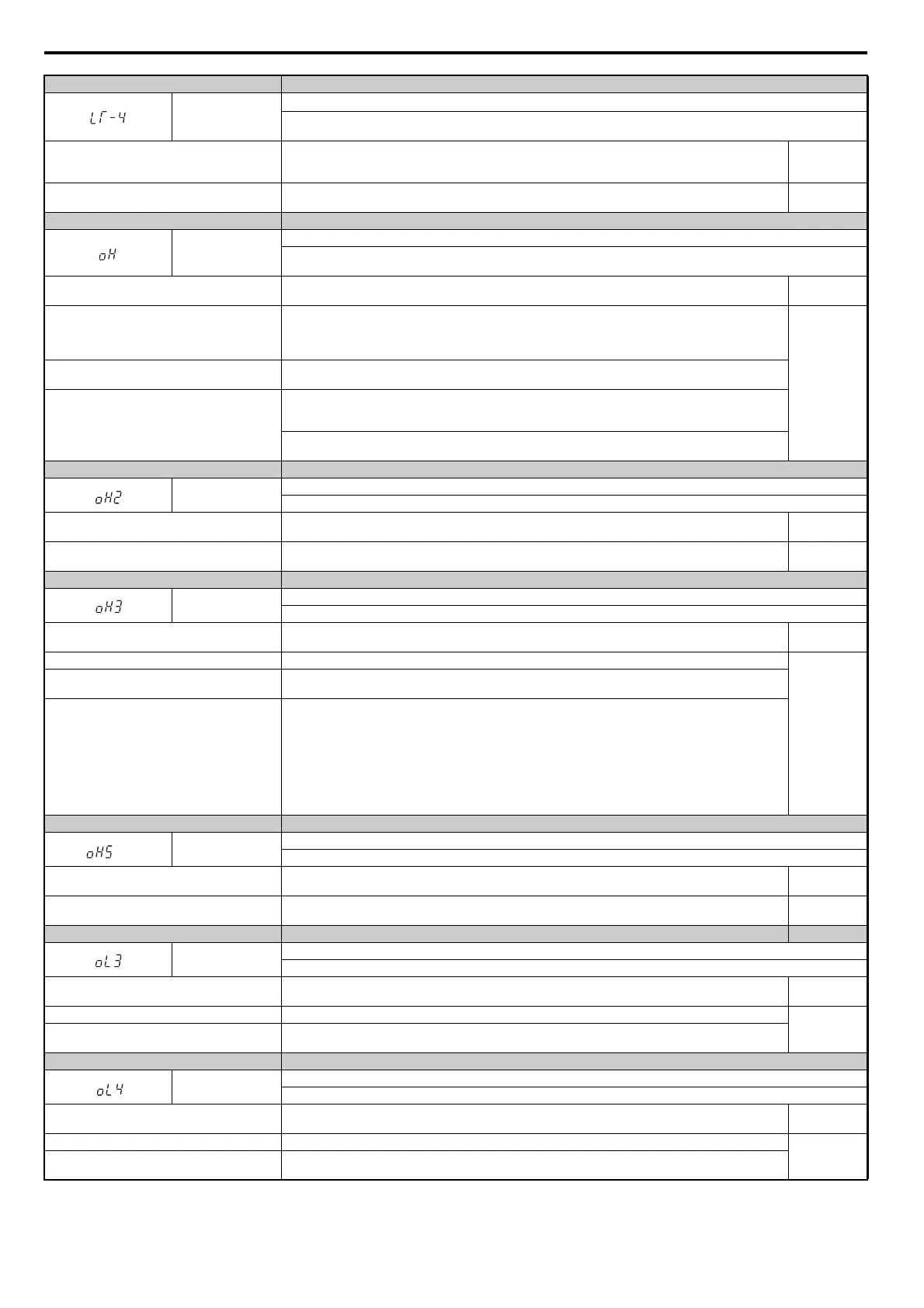

6.5 Alarm Detection

354 YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual

Digital Operator Display Minor Fault Name

LT-4

IGBT Maintenance Time (50%)

IGBT

s have reached 50% of their expected performance life.

Note: If H2- = 2F, the signal will close at the maintenance period. The signal will not close if H2- = 10.

Cause Possible Solutions

Maintenance

Ti

me

(H2- = 2F)

IGBTs have reached 50% of their expected

perf

ormance life.

Check the load, carrier frequency, and output frequency. YES

Digital Operator Display Minor Fault Name

oH

Heatsink Overheat

The t

emperature of the heatsink exceeded the overheat pre-alarm level set to L8-02 (90-100C). Default value for L8-02 is

determined by drive capacity (o2-04).

Cause Possible Solutions

Minor Fault

(H2- = 10)

Surrounding temperature is too high

• Check the surrounding temperature.

• Improve the air circulation within the enclosure panel.

• Install a fan or air conditioner to cool surrounding area.

• Remove anything near drive that may cause extra heat.

YES

Internal cooling fan has stopped.

• Replace the cooling fan. Refer to Cooling Fan Co

mponent Names on page 384.

• After replacing the drive, reset the cooling fan mai

ntenance parameter to (o4-03 = “0”).

Airflow around the drive is restricted.

• Provide proper installation space around t

he drive as indicated in the manual. Refer to Installation Orientation

and Spacing on page 46.

• Allow for the specified space and ensure that there is

sufficient circulation around the control panel.

• Check for dust or foreign materials clogging cooling fan.

• Clear debris caught in the fan that restricts air circulation.

Digital Operator Display Minor Fault Name

oH2

Drive Overheat Warning

“D

rive Overheat Warning” was input to a multi-function input terminal, S1 through S8 (H1-= B)

Cause Possible Solutions

Minor Fault

(H2- = 10)

An external device triggered an overheat warning in

th

e drive.

• Search for the device that tripped the overheat warning.

• Solving the problem will clear the warning.

YES

Digital Operator Display Minor Fault Name

oH3

Motor Overheat

The m

otor overheat signal entered to a multi-function analog input terminal exceeded the alarm level (H3-02, H3-06 or H3-10 = E).

Cause Possible Solutions

Minor Fault

(H2- = 10)

Motor thermostat wiring is fault (PTC input). Repair the PTC input wiring.

YES

There is a fault on the machine side (e.g., the

ma

chine is locked up).

• Check the status of the machine.

• Remove the cause of the fault.

Motor has overheated.

• Check the load size, accel/de

cel times, and cycle times.

• Decrease the load.

• Increase accel and decel times (C1-01 to C1-08).

• Adjust the preset V/f pattern (E1-04 through E1-10). This

will mainly involve reducing E1-08 and E1-10.

Note: Do

not lower E1-08 and E1-10 excessively, because this reduces load tolerance at low speeds.

• Check the motor-

rated current.

• Enter motor-rated current on motor nameplate (E2-01).

• Ensure the motor cooling syst

em is operating normally.

• Repair or replace the motor cooling system.

Digital Operator Display Minor Fault Name

<1>

oH5

Motor Overheat (NTC Input)

The mot

or temperature exceeded the level set in L1-16 (or L1-18 for motor 2).

Cause Possible Solution

Minor Fault

(H2- = 10)

Motor has overheated.

• Reduce the load.

• Check the ambient temperature.

YES

Digital Operator Display Minor Fault Name

oL3

Overtorque 1

Drive output current (or torque in OLV, CLV, AOLV/PM, CLV/PM) was greater than L6-02 for longer than the time set in L6-03.

Cause Possible Solutions

Minor Fault

(H2- = 10)

Inappropriate parameter settings. Check parameters L6-02 and L6-03.

YES

There is a fault on the machine side (e.g., the

ma

chine is locked up).

• Check the status of the machine.

• Remove the cause of the fault.

Digital Operator Display Minor Fault Name

oL4

Overtorque 2

Dri

ve output current (or torque in OLV, CLV, AOLV/PM, CLV/PM) was greater than L6-05 for longer than the time set in L6-06.

Cause Possible Solutions

Minor Fault

(H2- = 10)

Parameter settings are not appropriate. Check parameters L6-05 and L6-06.

YES

There is a fault on the machine side (e.g., the

ma

chine is locked up).

• Check the status of the machine being used.

• Remove the cause of the fault.

Loading...

Loading...