6241A/6242 DC Voltage Current Source/Monitor Operation Manual

A-2

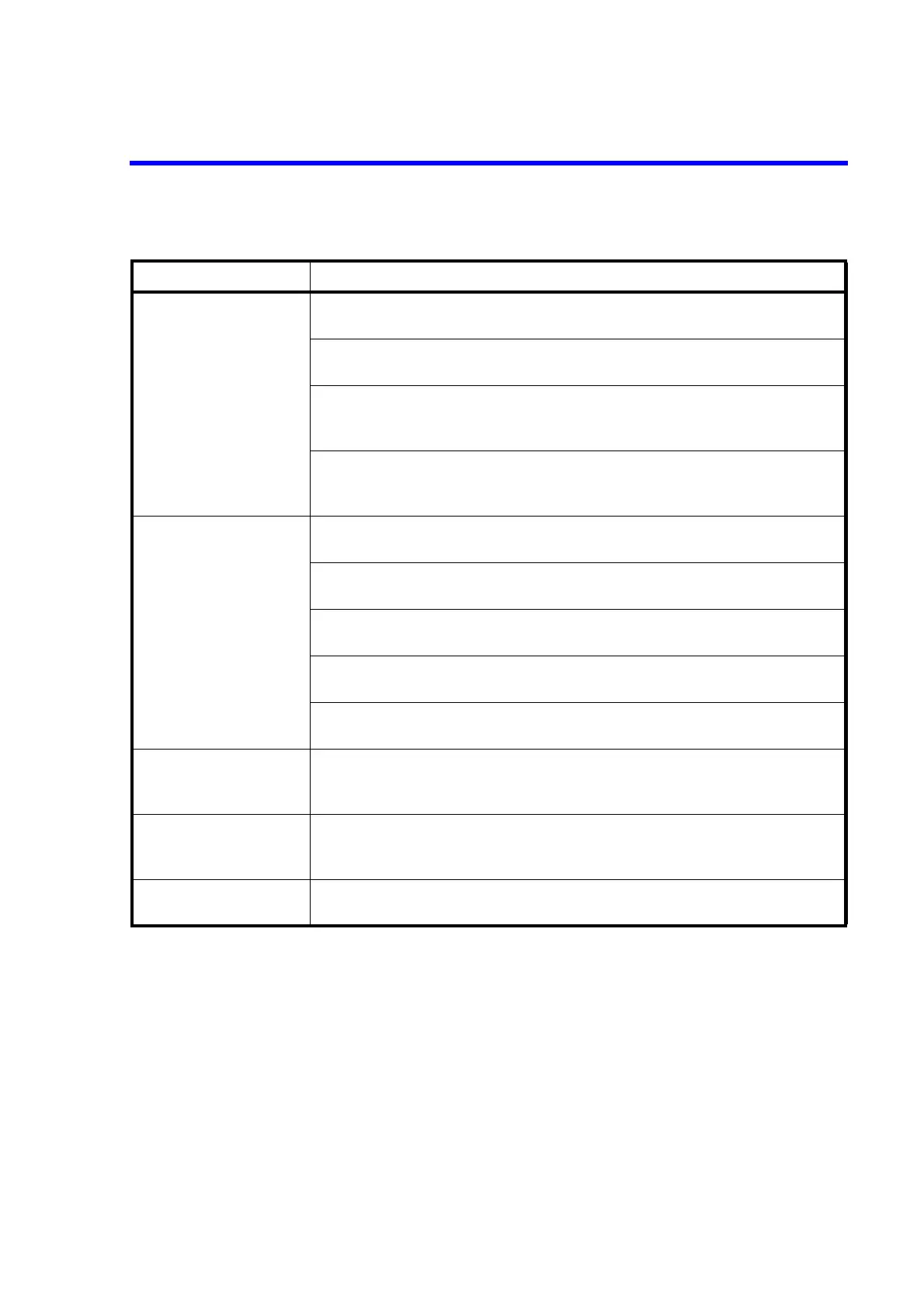

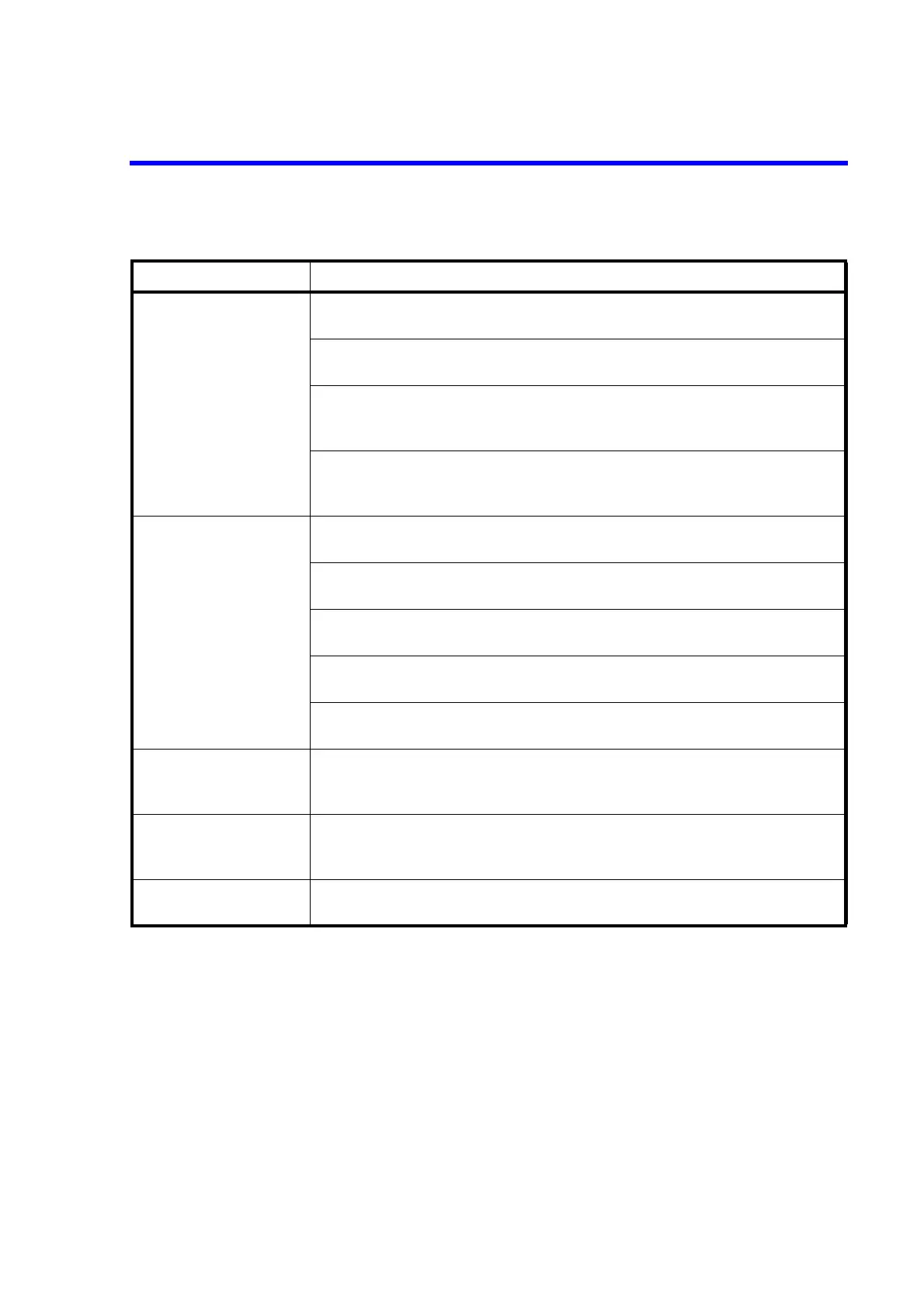

3. Measurement value is

not being output.

Cause:

Solution:

Unit in Standby or Suspended status.

Set to Operate and verify that the OPR indicator is ON.

Cause:

Solution:

Measurement is not ON.

Verify measurement ON/OFF setting.

Cause:

Solution:

When measuring in auto range, the value is unstable and the range

unconfirmed, therefore measurement data is not output.

Change to a fixed range and measure.

Cause:

Solution:

A trigger signal is not input even when the trigger signal cable is con-

nected to the external trigger.

Verify TRIG INPUT connection cable and the signal.

4. A source value or

measurement value

indication is unstable

or is in error.

Cause:

Solution:

Function or range settings have an error.

Verify the setting again.

Cause:

Solution:

Cable connection is wrong.

Verify cable connections again.

Cause:

Solution:

The cable is disconnected.

Verify the cables with the tester. If in error, replace it.

Cause:

Solution:

The cable is connected to a wrong terminal.

Verify cable connections again.

Cause:

Solution:

The induction noise scatters the measurement value.

Set the integration time to 1 PLC or over.

5. The measurement

value is over range.

Cause:

Solution:

When the NULL calculation value becomes twice or more of the value

of full-scale.

Raise the source value or limiter range.

6. Unable to input set-

tings with the mea-

surement control key.

Cause:

Solution:

While inputting with direct mode, the set value is at half-brightness and

only the green keys on the panel are enabled.

Press 123... key to complete the direct input mode.

7. A relay life error

occurred.

Cause:

Solution:

The Operate relay operated more than one million time.

In this case, contact an ADC CORPORATION sales representative.

Table A-1 Items to be Inspected before Requesting the Repair (2/2)

Q (Symptom) A (Cause and Solution)

Loading...

Loading...