Parameter descriptions

The settings of the current controllers should not be too dynamic in order to ensure a sufficient re-

serve range. The control tends to increased oscillations if the reverse range is reduced.

T

he dimensioning of the current controller parameters by calculation of the time constant is to be

done for a switching frequency of 2 kHz. For other switching frequencies, the values are adapted in-

ternally so that the setting can remain un-

c

hanged for all switching frequencies. The dynamic proper-

ties of the current controller improve if the switching and scanning frequency increases.

T

he fixed time interval for the modulation results in the following scanning frequencies of the current

controller via parameter

Switching Frequency 400.

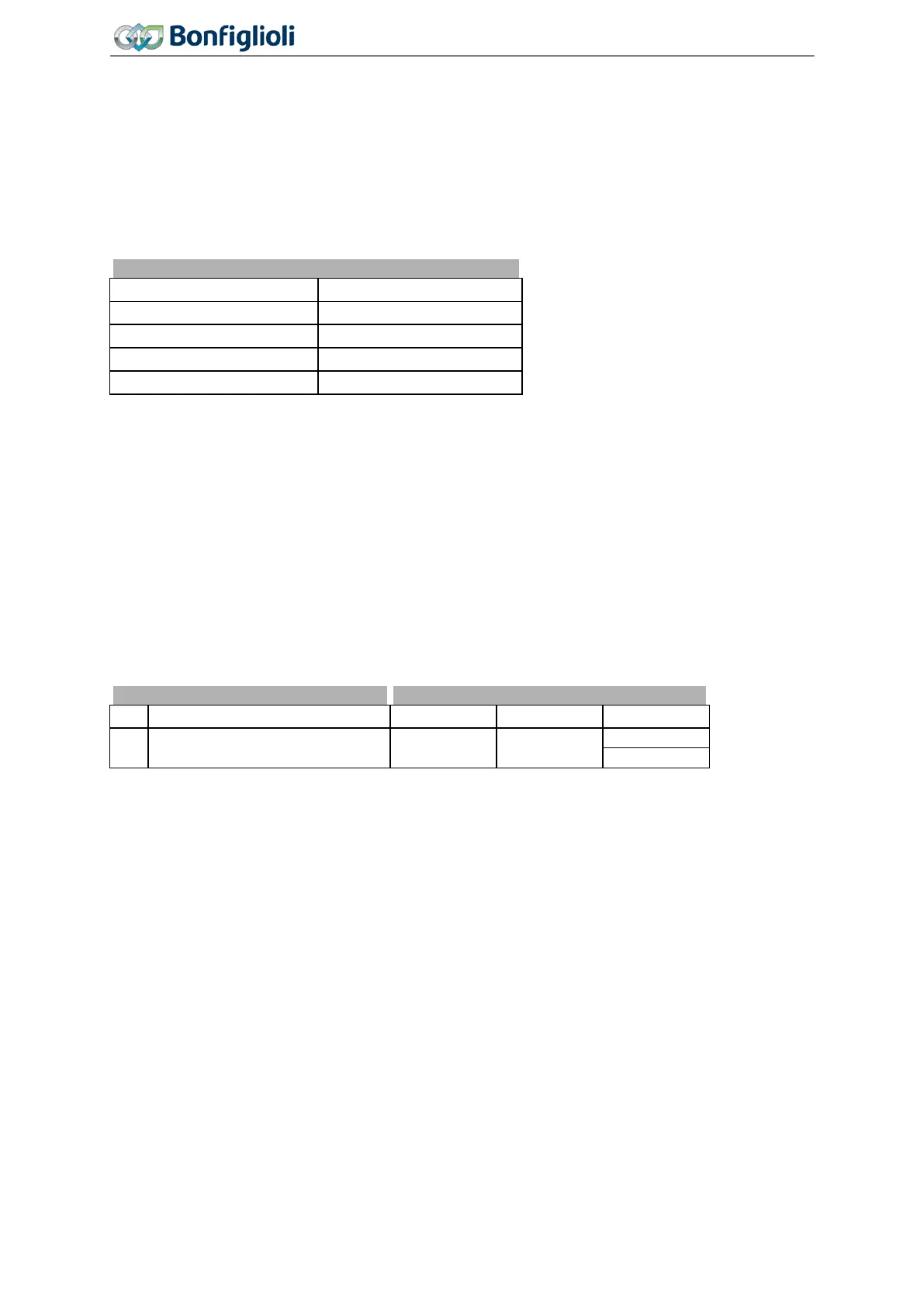

Switching frequency Scanning frequency

2 kHz 2 kHz

4 kHz 4 kHz

8 kHz 8 kHz

16 kHz 8 kHz

746 Cross-Coupling Factor

For an asynchronous motor (

Configuration 30 = 410) and synchronous motor (Configuration 30 =

610), the coupling between the flux-forming current Isd and the torque-forming current Isq can be

undone largely by the activated cross-coupling compensation. In this way, it is possible to impress the

torque-forming current in the machine more quickly and the speed control circuit has a lower tenden-

cy toward vibration.

The cross-coupling exists between the flux-forming current Isd and the torque-forming current Isq

and is caused by the voltage drop at the stator inductivity and the stator leakage inductivity. For this

reason, the cross-coupling increases with the stator frequency. The cross-coupling becomes particular-

ly apparent in the case of high stator frequencies at relatively small switching frequencies (e.g. 300 Hz

stator frequency at 4 kHz switching frequency), as with small switching frequencies, the current con-

troller slows down.

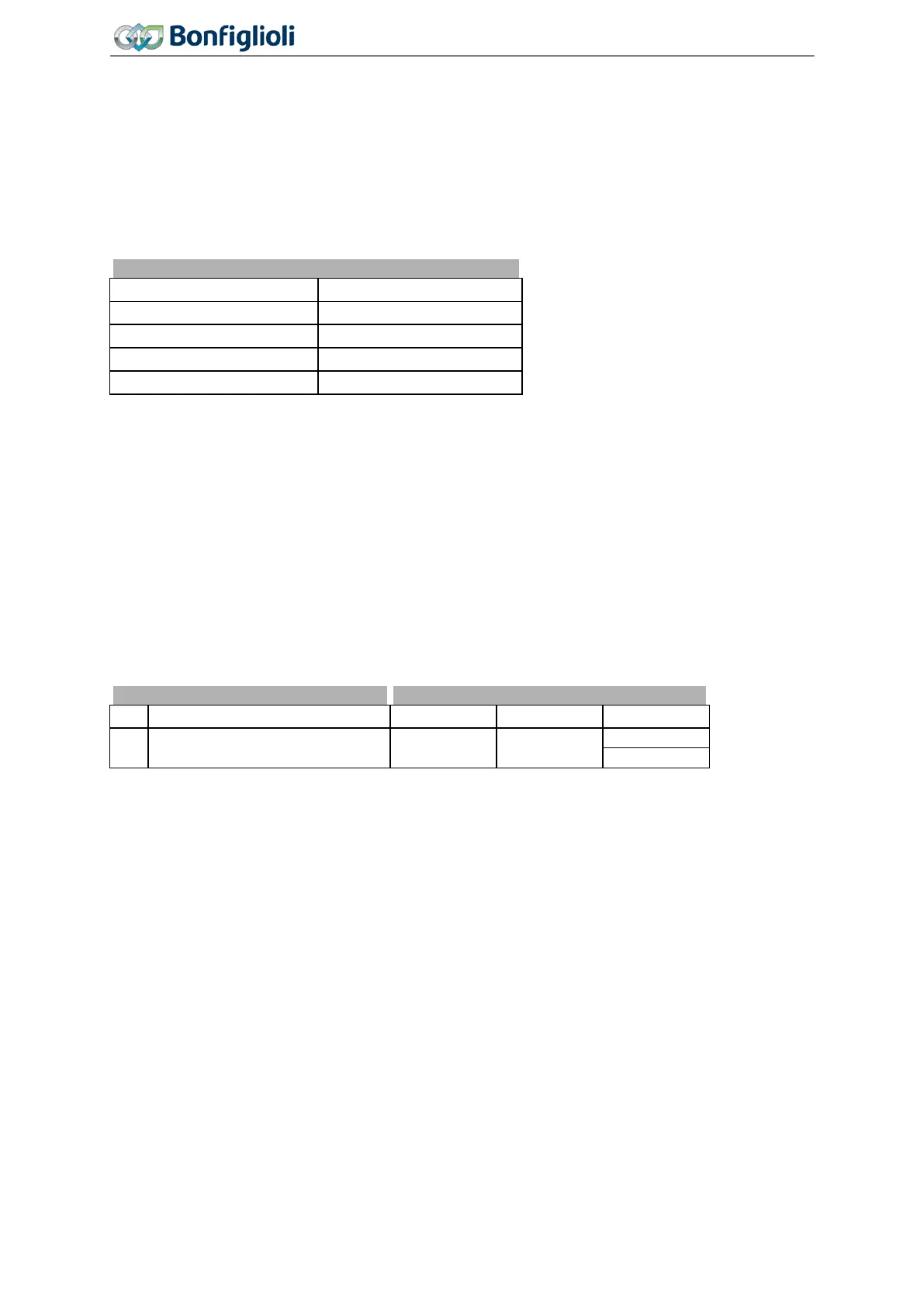

746 Cross-Coupling Factor 0.00% 300.00%

1)

Configuration 30 = 410

2)

Configuration 30 = 610

Cross-coupling compensation can be optimized as follows:

• First, set the speed controller. To that end, define reference speed jumps at small rotary frequen-

cies. See chapter 7.9.5.3 "Speed controller".

• Set a speed of approx.

2

3

of the rated speed.

• Define reference speed jumps again. During the accelerations, currents Isq of approx. 50% of the

rated current should occur.

• Starting from 0%, increase the value of

Cross-Coupling Factor 746 in steps of 25%, for exam-

ple.

• The influence by Isq on Isd during the reference speed jumps should decrease with increasing

values of

Cross-Coupling Factor 746. For checking, signal sources Isd and Isq can be os-

cilographed using the scope function of the PC user software. A minimum influence should be

reached at 100%.

• Set the

Cross-Coupling Factor 746 to a value slightly below the determined optimum value.

Very high values for

Cross-Coupling Factor 746 (e.g. 125%) may result in an overcurrent circuit

break.

230

Operating Instructions

Agile

06/2013 Control functions

Loading...

Loading...