9. Jam Display Field Service Ver. 1.0 Aug. 2005

28

SD-502

Troubleshooting

9.3 Solution

9.3.1 Initial Check Items

• When a paper misfeed occurs, first make checks of the following initial check items

9.3.2 Creasing Section Misfeed

A. Detection Timing

B. Action

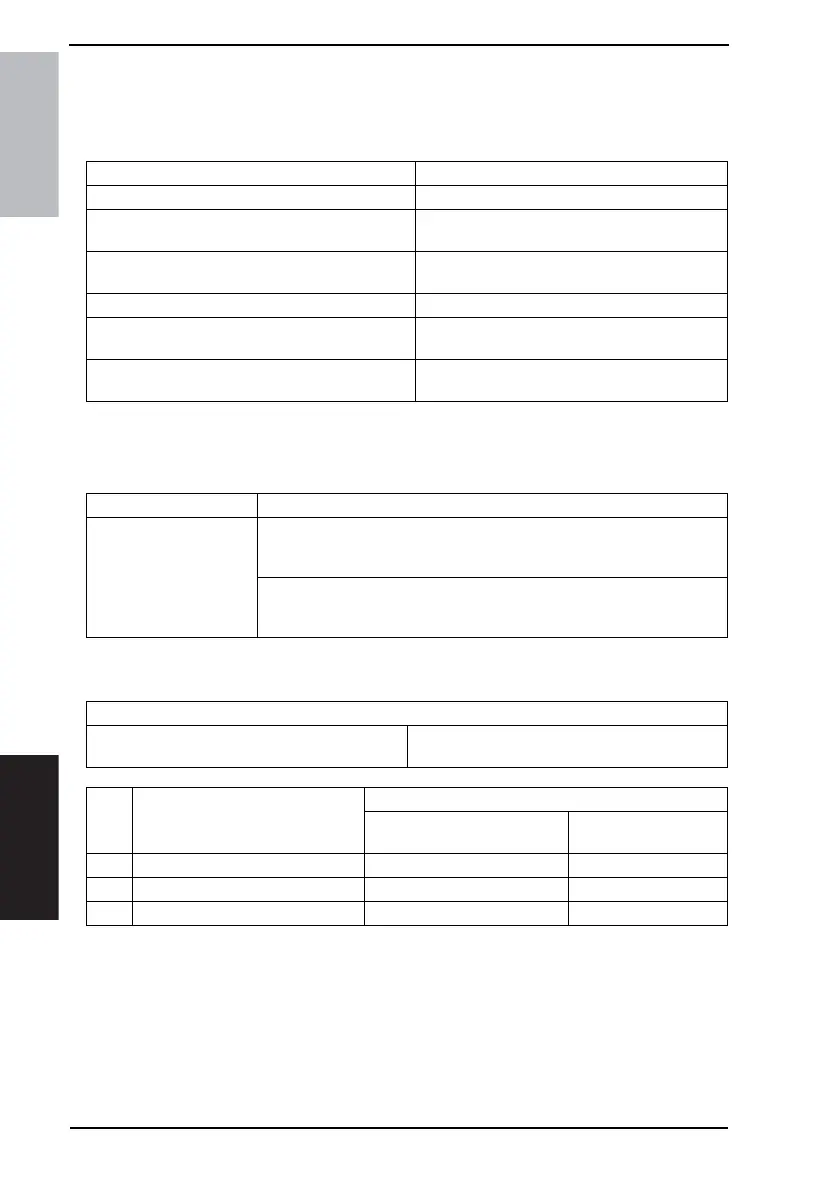

Check Item Action

Does paper meet product specifications? Change paper.

Is paper curled, wavy, or damp.

Change paper.

Instruct user in correct paper storage.

Is a foreign object present along the paper path, or

is the paper path deformed or worn?

Clean or change the paper path.

Are rolls/rollers dirty, deformed, or worn? Clean or change the defective roll/roller.

Are the Edge Guide and Trailing Edge Stop at cor-

rect position to accommodate paper?

Set as necessary.

Are actuators found operational as checked for cor-

rect operation?

Correct or change the defective actuator.

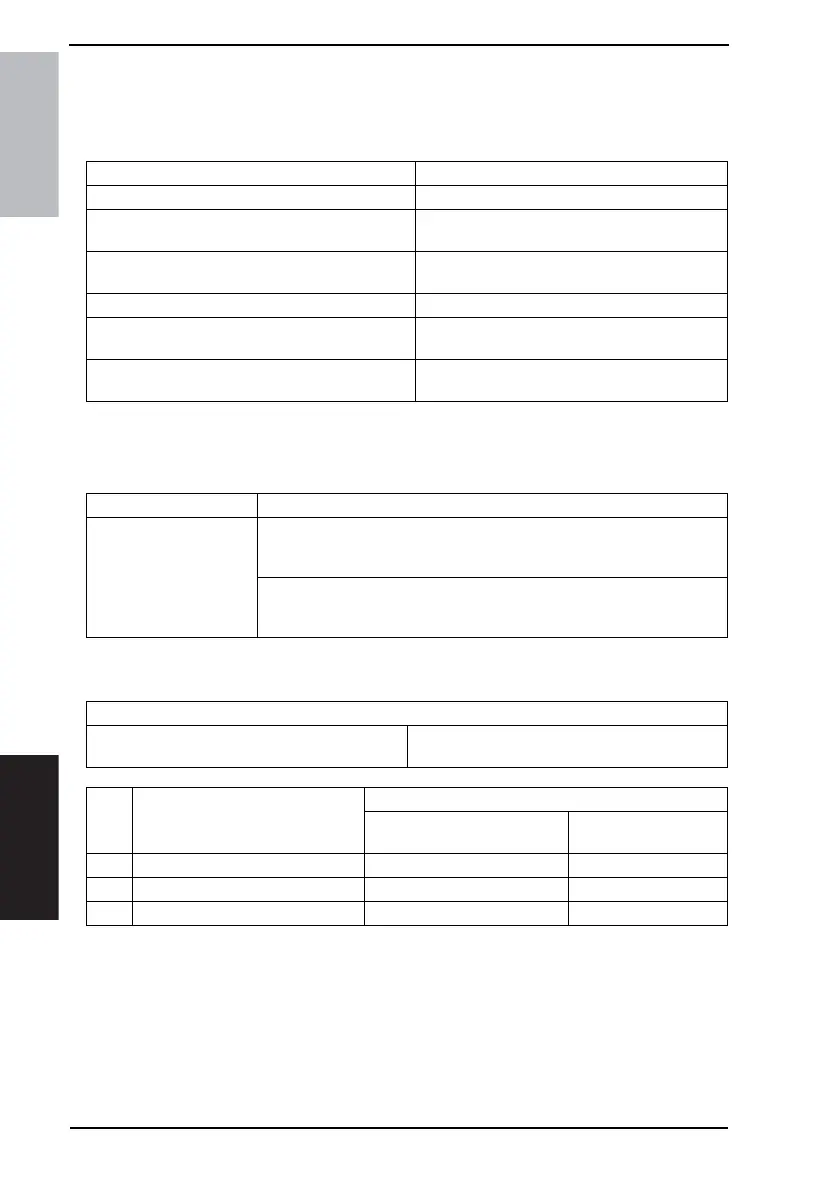

Type Description

Creasing Section

misfeed detection

The Entrance Sensor (PC4-FN) is not blocked even after the set period of

time has elapsed after the Entrance Motor (M3-FN) is energized (beginning

of backward rotation operation).

The Entrance Sensor (PC4-FN) is not unblocked even after the set period

of time has elapsed after the Entrance Motor (M3-FN) is energized (begin-

ning of forward rotation operation).

Relevant Electrical Parts

Entrance Motor (M3-FN)

Entrance Sensor (PC4-FN)

Main Control Board (PWB-C SK)

Step Action

WIRING DIAGRAM

Control Signal

Location

(Electrical Component)

1 Initial check items - -

2 PC4-FN I/O check PWB-A FN PJ25A FN-4 (ON) FS-508 B-6

3 Change PWB-C SK - -

Loading...

Loading...