Field Service Ver. 1.0 Aug. 2005 21. Image quality problem

251

bizhub 200/250/350

Troubleshooting

21. Image quality problem

21.1 How to identify problematic part

• This chapter is divided into two parts: “Initial Check Items” and “Troubleshooting Proce-

dure by a Particular Image Quality Problem.”

• When an image quality problem occurs, first go through the “Initial Check Items” and, if

the cause is yet to be identified, go to “Troubleshooting Procedure by a Particular Image

Quality Problem.”

21.2 Initial Check Items

21.2.1 Initial Check Items 1

• Determine if the failure is attributable to a basic cause or causes.

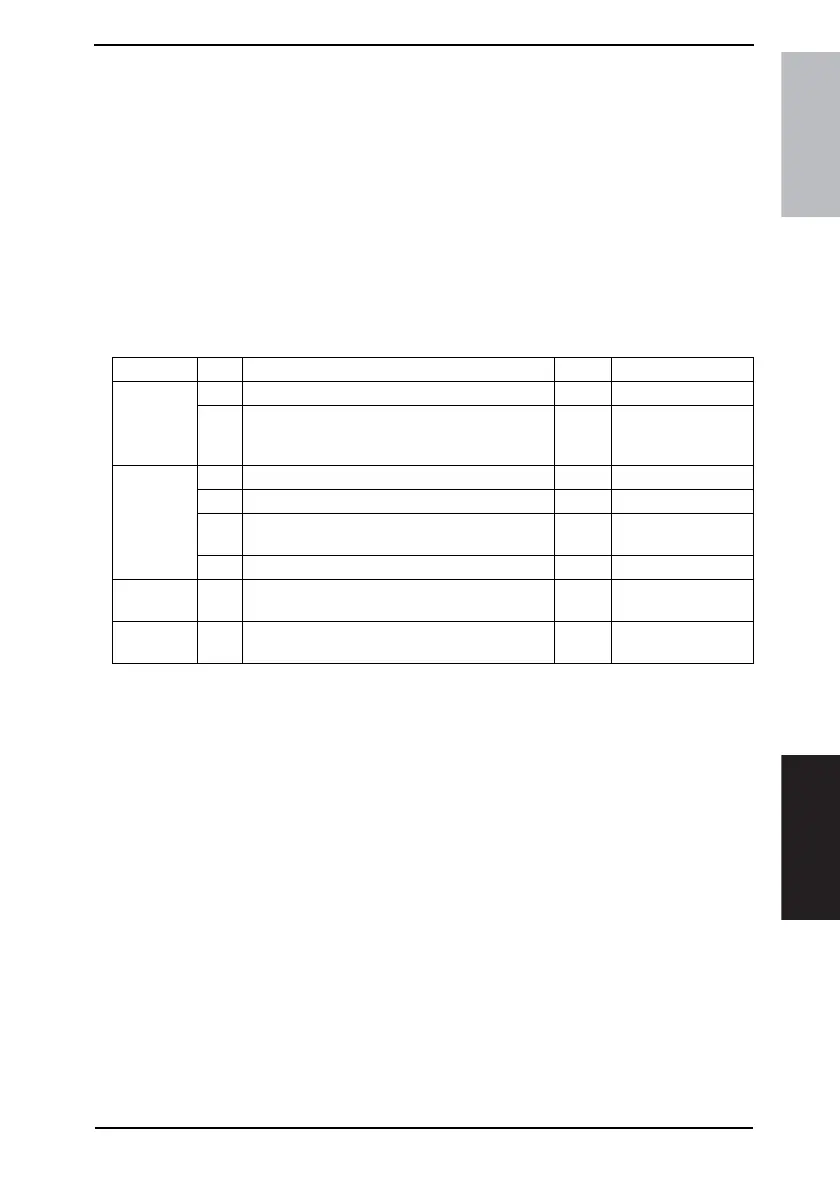

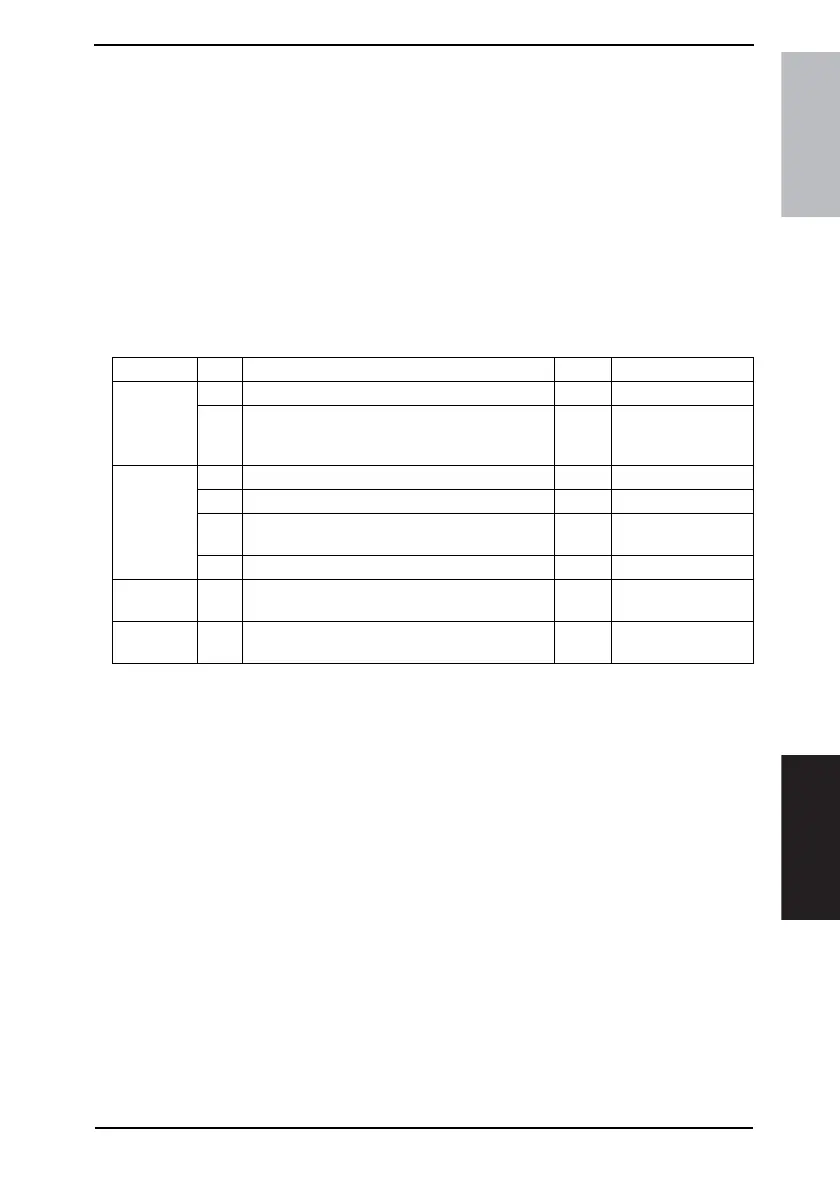

Section Step Check Item Result Action

Paper

1 Recommended paper is used. NO Instruct user.

2 Paper is damp. YES

Replace paper.

Instruct user on

proper paper storage.

Original

3 Original not flat. YES Correct

4 Faint original (light pencil, etc.) YES Instruct user.

5

Highly transparent original (OHP transparencies,

etc.)

YES Instruct user.

6 Dirty or scratched Original Glass. YES Clean or Replace.

PM parts 7

PM parts relating to image formation have

reached the end of cleaning/replacement cycles.

YES Clean or Replace.

Adjustment

items

8

There are settings that can be readjusted to rem-

edy the image failure.

YES Readjust.

Loading...

Loading...