Chapter 2 Installation 2.3 How to Install

77

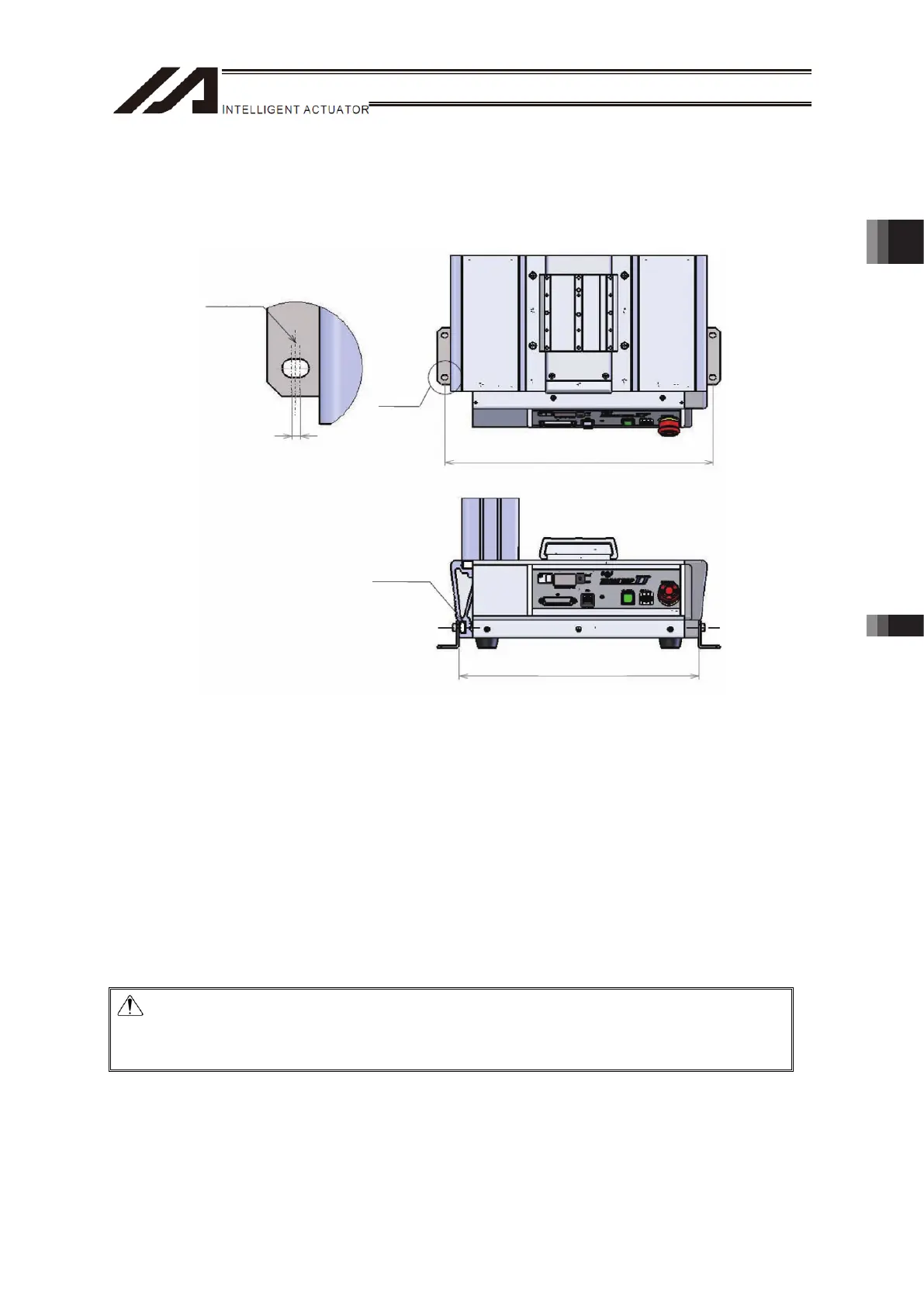

To affix the unit, purchase the unit fixing bracket in option or prepare a bracket separately.

When you make your own bracket, have oblong holes to secure margin to the pitch between holes

in the direction of the product width, and make sure the straight portion on the oblong holes is 3mm

or more.

Nominal

Dimension

Detail of Oblong Hole

Slotted

Hole

Nominal Dimension for Hole Pitch

Product Width: 340

+2

-1

T-Groove

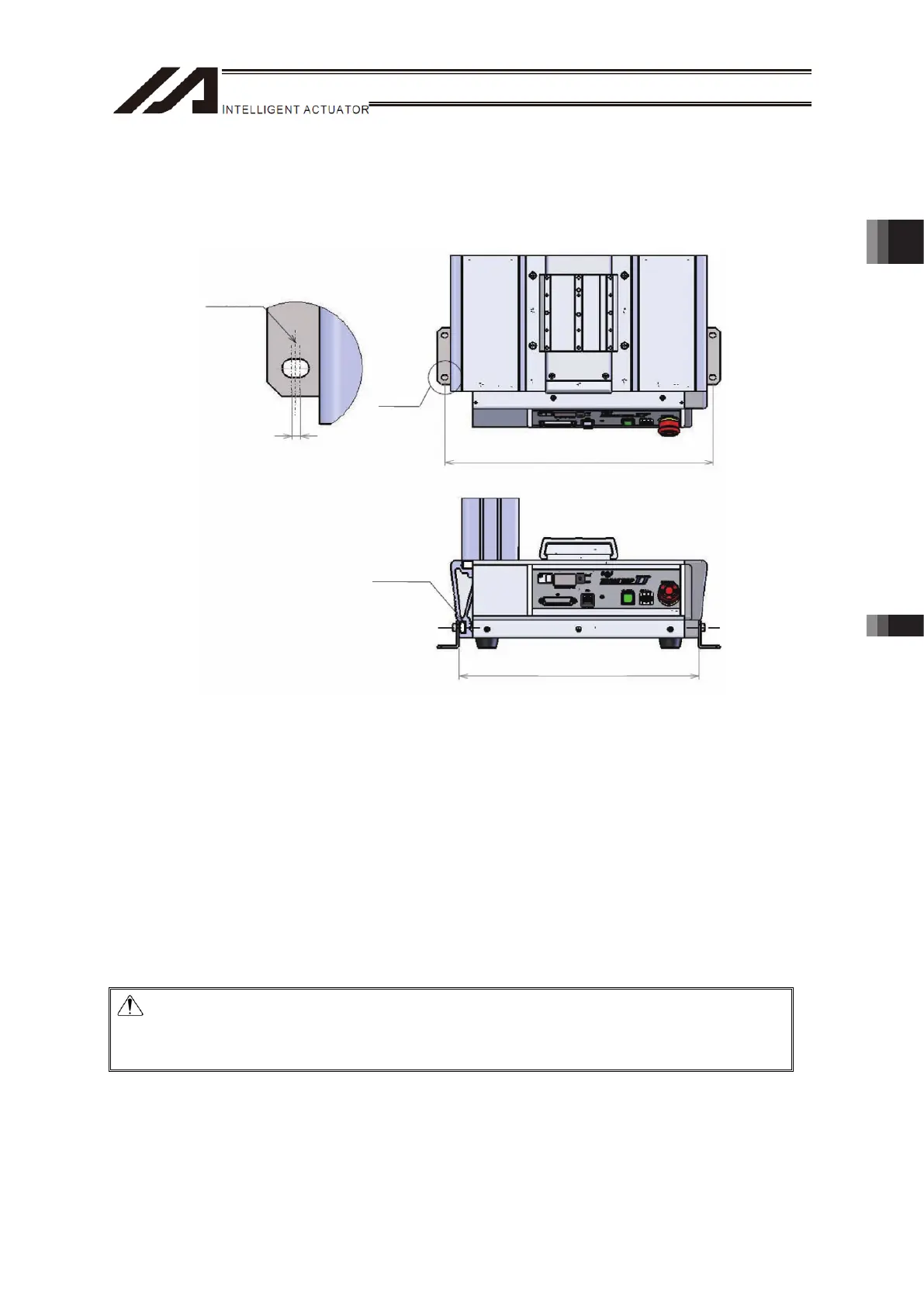

2.3.3 Attachment of the Transported Object

There are screw holes and reamed holes equipped on the slider surface of each axis in order to affix

transported objects.

For more details refer to the [Chapter 8 External Dimensions].

Tightening screws

• Use hexagonal socket head bolts for the male threads for installing the attachment.

• It is recommended to use high-tensile bolts with ISO-10.9 or more.

• Make sure to have the effective length of screw engagement described below or more for the

tightening of a bolt and a female screw.

When female screw is on steel → thread length same as nominal diameter

When female screw is on aluminum → thread length 1.8 times longer than nominal diameter

Caution: Pay special attention when selecting the bolt length. In case that an inappropriate

length of a bolt is applied, it may cause a drop in the operation accuracy or an

unexpected accident due to a damage to the tapped holes, insufficient strength

of actuator attachment or an interference with the operating area.

Loading...

Loading...