Image 6.11: Mechanical system axis correction (① = slack in gearing)

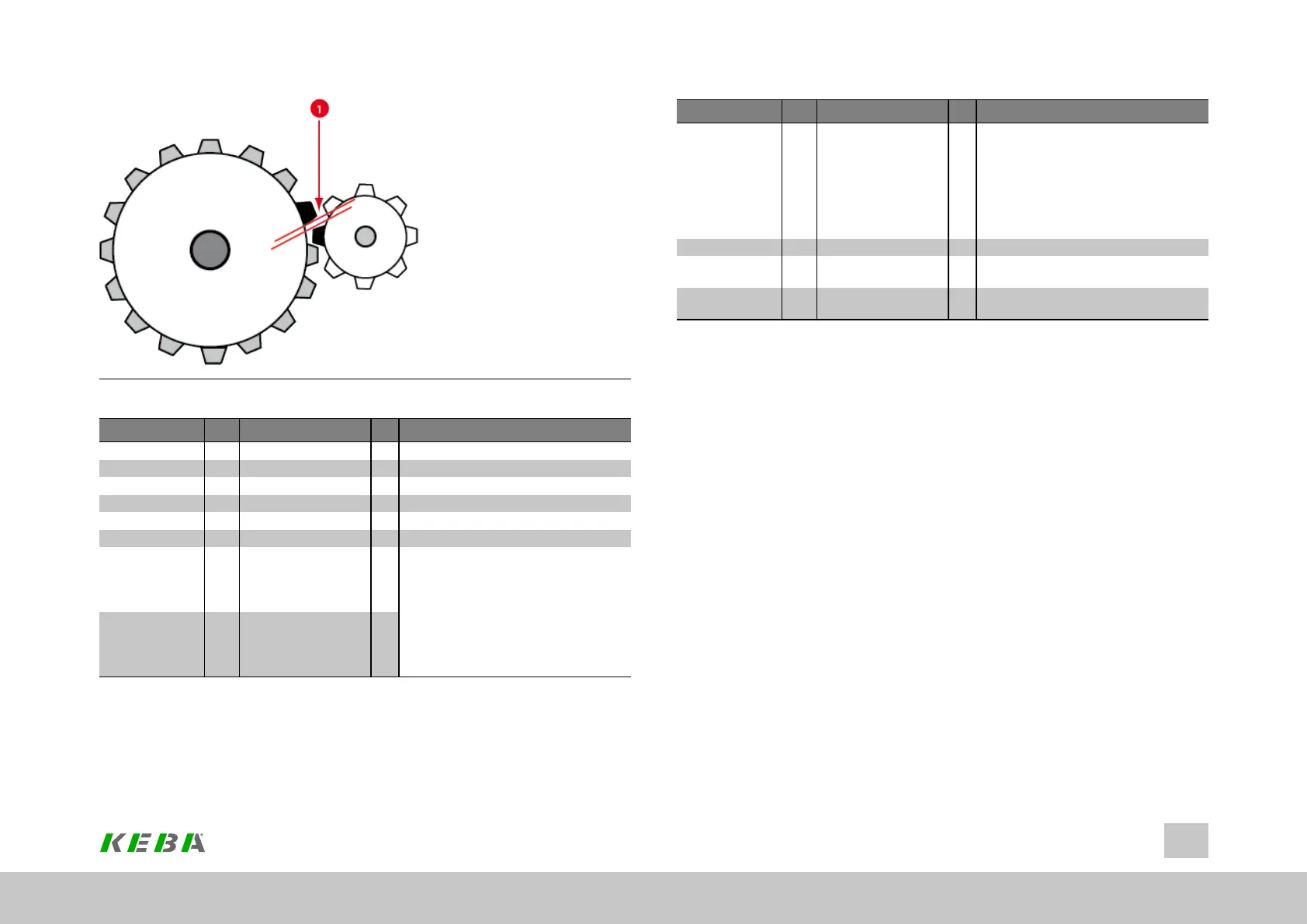

P No. Index Name / Setting Unit Description

530 0 ENC_Encoder1Sel Channelselectionforthe1stencoderused

531 0 ENC_Encoder2Sel Channelselectionforthe2ndencoderused

590 0 ENC_ACOR_Sel

0(=OFF) Noencoderselected

1(=1stEncoder) 1.encoderselected

2(=2ndEncoder) 2.encoderselected

591 0 ENC_ACOR_PosStart Definitionofcorrectionrange:Therangeis

definedbyparametersP 0591 ENC_ACOR_

PosStartStartpositionand

P 0592 ENC_ACOR_PosEndendposition.

Thestartpositionisuser-specified;theend

positionisdeterminedonthedevicesidefrom

themaximumvalueofcorrectiontable

interpolationpointsusedandtheinterpolation

pointpitch.

592 0 ENC_ACOR_PosEnd

Table 6.36: Axis correction parameters

ID No.: 0842.26B.5-01Date: 09.2020

ServoOne- Device Help

103

6 Encoder

P No. Index Name / Setting Unit Description

593 0 ENC_ACOR_PosDelta Interpolationpointpitch:Thepositionsatwhich

thecorrectioninterpolationpointsareplottedare

definedviaparametersP 0593 ENC_ACOR_

PosDeltaInterpolationpointpitchandP 0591

ENC_ACOR_PosStartStartposition.Between

thecorrectioninterpolationpoints,the

correctionvaluesarecalculatedbycubicspline

interpolation.

594 0 ENC_ACOR_Val Actualposition

595 0-250 ENC_ACOR_VnegTab Valuesofthecorrectiontablefornegative

directionofrotationinuserunits.

596 0-250 ENC_ACOR_VposTab Valuesofthecorrectiontableforpositive

directionofrotationinuserunits.

Table 6.36: Axis correction parameters (continue)

Loading...

Loading...