Starting production

108 ProtoMat

®

S62

Adjusting the milling depth/width

If you activated the Stop after change option when setting up the tools,

the "Stop for depth adjustment ?" message will appear after a milling

tool has been picked up.

1. In order to adjust the milling depth on the basis of a sample milling:

Click on Yes.

Note: If you click on No, the production will continue with the current depth

adjustment.

2. Using the current tool, create a milling track approximately 10 mm

in length on a section of the base material you do not need (see

chapter ‚ "Creating a milling track", on page 75).

3. Check the milling track with a measuring microscope:

– Is the copper completely milled out?

– For conical cut mills (Universal Cutter, Micro Cutter): Does the mill-

ing width match the value displayed in BoardMaster?

4. To correct the milling depth/width:

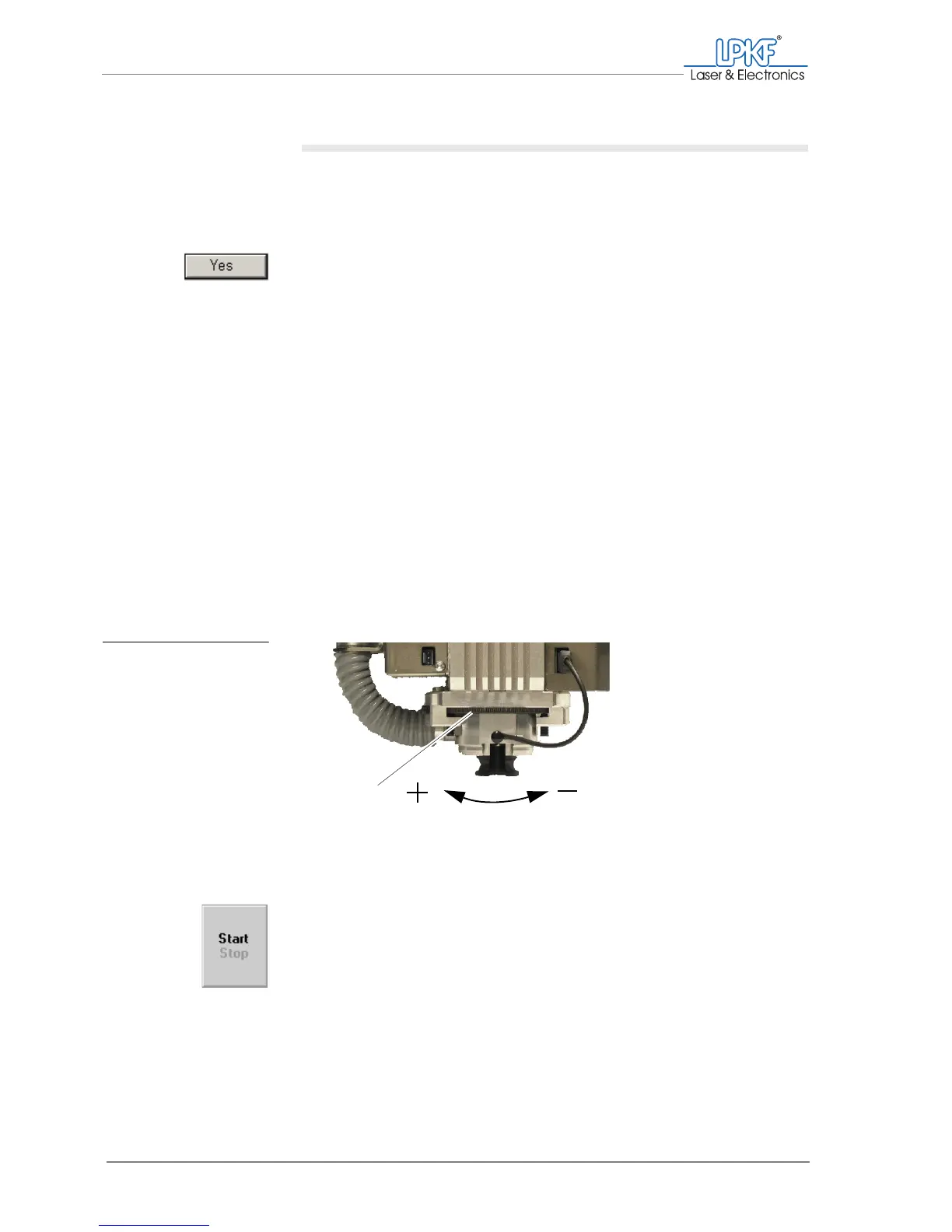

– Turn the adjusting wheel on the milling/drilling head to the left to

mill deeper/wider.

– Turn the adjusting wheel on the milling drilling head to the right

to remove less material/mill a narrower track.

Note: The milling width will change per raster step by approximately 4 µm

(Universal Cutter) or approximately 2.3 µm (Micro Cutter).

– Create a further test track to check the new milling depth/width.

5. Click on Start.

[ ] The production will be continued

Fig. 48: Adjusting the mill-

ing width

1 Setting wheel for milling depth limiter

1

Loading...

Loading...