What you should know

Operating Manual 7.1 Rev.: 18.06.2008 39

3.5 The 2.5 D function

With its software-controlled 2.5 D function, the ProtoMat

®

S62 is perfect

for milling contours and cut-outs in thickwalled housing materials that

make high material removals necessary. The material is removed in sev-

eral cycles to protect the tool.

You can also mill stepped crevices, for example component pockets for

SMD loading, with the 2.5 D function.

Required accessories You will need the vacuum table (which can be purchased as an acces-

sory) to guarantee an exactly flat position when performing 2.5 D surface

milling. Contour/cut-out milling can also be performed with the basic

equipment in 2.5 D mode.

For optimum dust extraction, the milling depth limiter base must be

replaced with the LPKF brush head (which is available as an accessory)

when processing in 2.5 D mode (see chapter ‚ "Dismounting the plastic

base/brush head", on page 62).

Usable tools It is only possible to use the End Mill long 1/8" and the Contour Router in

2.5 D processing. The End Mill (RF) 1/8" is not suitable for the

2.5 D function.

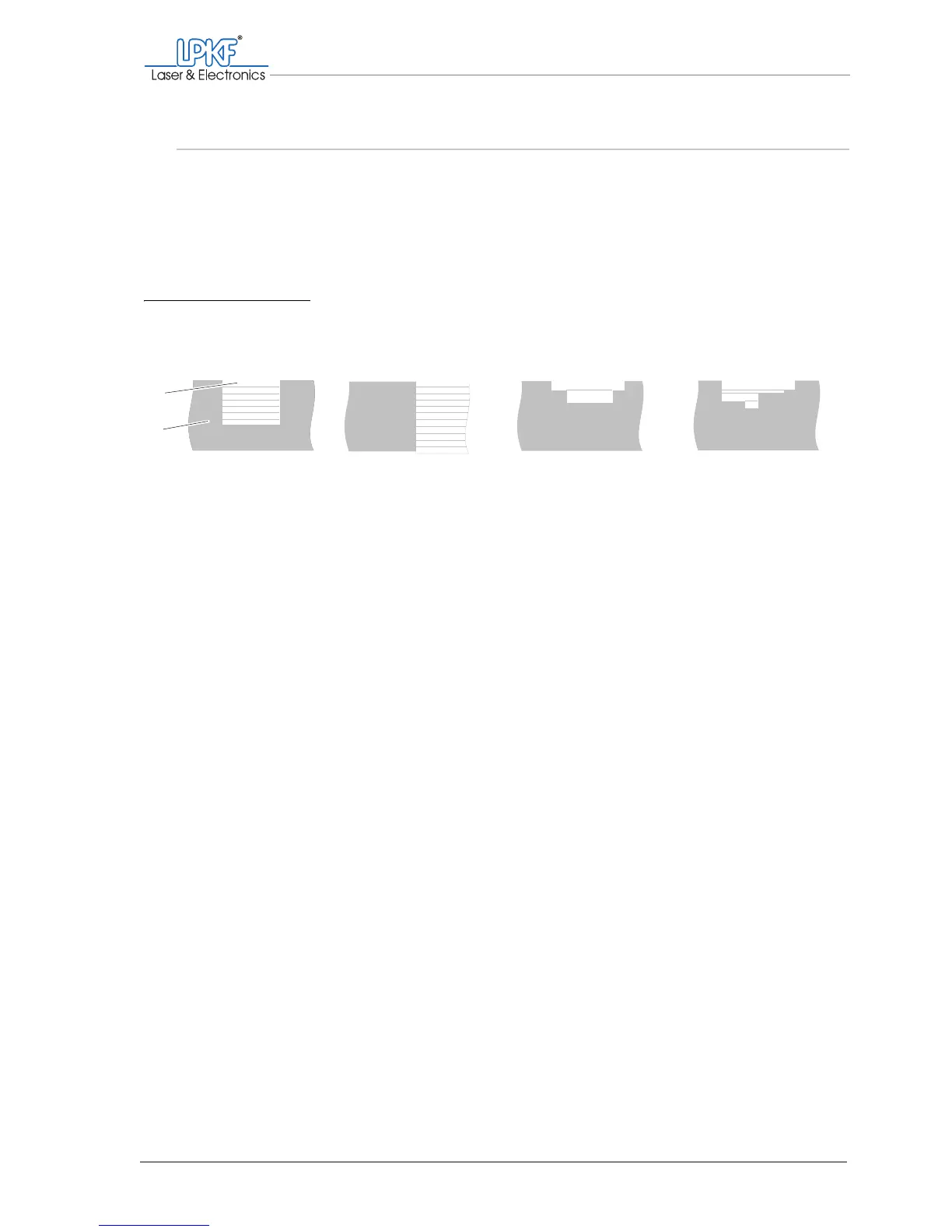

Fig. 16: 2,5 D processing (application examples))

1 Deep milling in multiple

cycles

2 Contour milling in multiple

cycles

3 Stage milling in two cycles 4 Multi-stage milling with different

tool diameters

a - Milling cycle, b - Material

12 34

a

b

Loading...

Loading...