What you should know

Operating Manual 7.1 Rev.: 18.06.2008 33

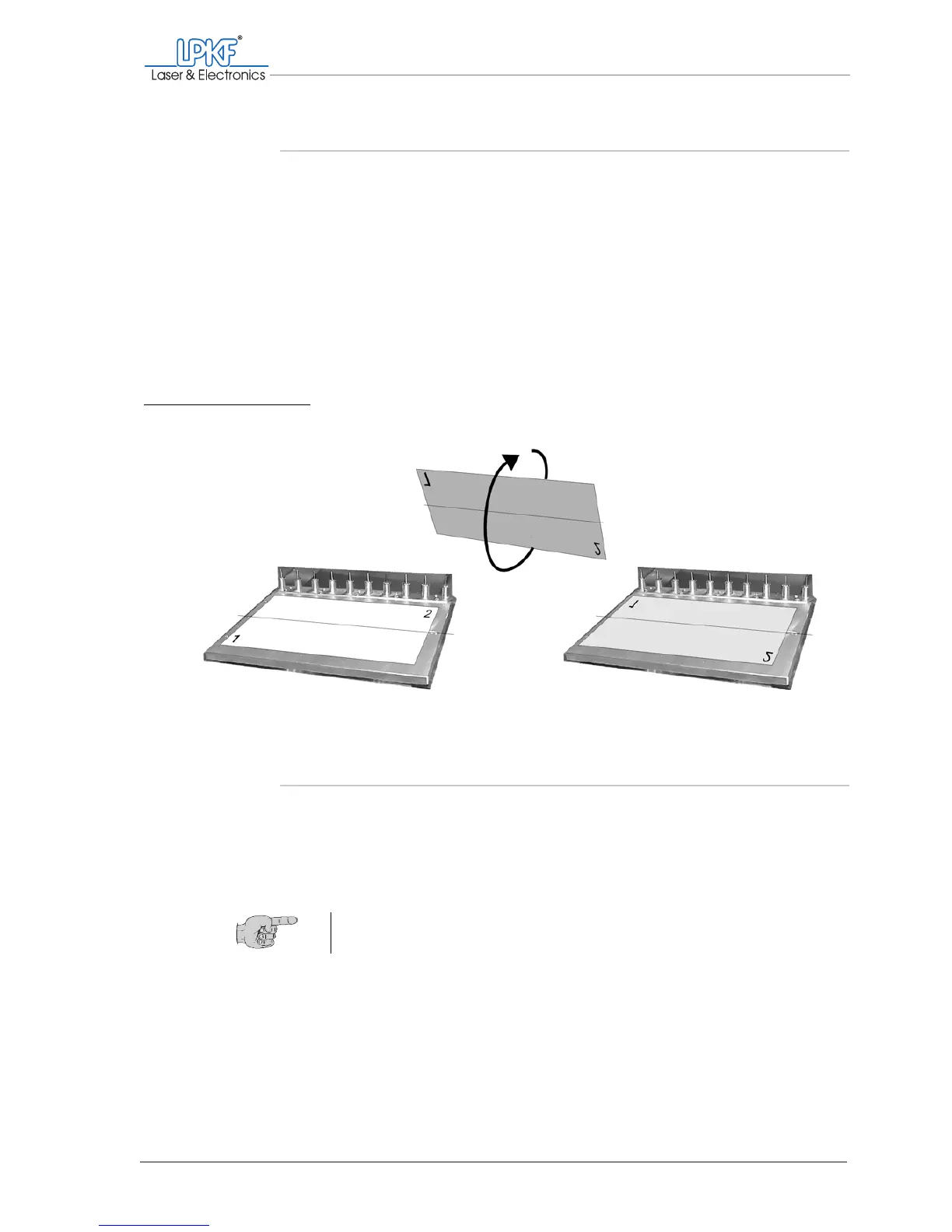

3.2.1 The pass hole system

The ProtoMat

®

S62 is delivered from the factory with a pass hole system

for base material in standard size 9" x 12". It comprises two pass hole

pins mounted in exchangeable plastic strips. The plastic strips can be

used more than once and moved individually in the X direction. Accord-

ingly, multiple pass hole positions can be set up for different base mate-

rial sizes.

The pass hole pins mounted on the traversing table are positioned

exactly on the mirror axis of the co-ordinate system. If the base material

is turned through this (longitudinal) axis to process the second side, the

production data is automatically executed precisely to fit on the base

material.

3.2.2 Material fastening

The material must lie flat on the drilling underlay to ensure the desired

material removal rate across all areas when milling. Fasten it at the

edges using adhesive tape which will not leave any traces of residue

when removed.

Fig. 14: Turning the material through the mirror axis

Tip: For flexible materials use the optional vacuum table to fasten the

material in a perfectly flat position.

Loading...

Loading...