G.10

SEL-351A Relay Instruction Manual Date Code 20080213

Setting SELOGIC Control Equations

SEL

OGIC Control Equations

The individual SELOGIC control equation settings explanations (referenced in

SEL

OGIC Control Equation Settings (Serial Port Command SET L) on

page SET.15) discuss whether it makes logical sense to set the given SEL

OGIC

control equation setting to 0 or 1 for certain criteria.

Set SELOGIC Control Equations Directly to 1 or 0—Example

Of special concern are the SELOGIC control equation torque control settings

67P1TC through 51QTC for the overcurrent elements. In the factory settings

the SEL-351A ships with in a standard relay shipment, these are all set

directly to logical 1. See these factory settings in SHO Command (Show/View

Settings) on page 10.25.

If one of these torque control settings is set directly to logical 1, e.g.,

51PTC = 1 (set directly to logical 1)

then the corresponding overcurrent element (e.g., phase time-overcurrent

element 51PT) is subject only to the directional control. See Figure 3.14 for

phase time-overcurrent element 51PT logic.

If the directional control enable setting E32 = N (and 51PTC = 1), then time-

overcurrent element 51PT is enabled (assuming pickup setting 51PP is made)

and nondirectional.

SELOGIC Control

Equation Limitations

Any single SELOGIC control equation setting is limited to 15 Relay Word bits

that can be combined together with the SEL

OGIC control equation operators

listed in Table G.1. If this limit must be exceeded, use a SEL

OGIC control

equation variable (SEL

OGIC control equation settings SV1–SV16) as an

intermediate setting step.

For example, assume that the trip equation (SEL

OGIC control equation trip

setting TR) needs more than 15 Relay Word bits in its equation setting. Instead

of placing all Relay Word bits into TR, program some of them into the

SEL

OGIC control equation setting SV1. Next use the resultant SELOGIC

control equation variable output (Relay Word bit SV1) in the SEL

OGIC control

equation trip setting TR.

Note in Table G.3 that the SEL

OGIC control equation variables (SELOGIC

control equation settings SV1–SV16) are processed after the trip equation

(SEL

OGIC control equation trip setting TR). Thus, any tripping via Relay

Word bits SV1 through SV16 can be delayed as much as 1/4 cycle. For most

applications, this is probably of no consequence.

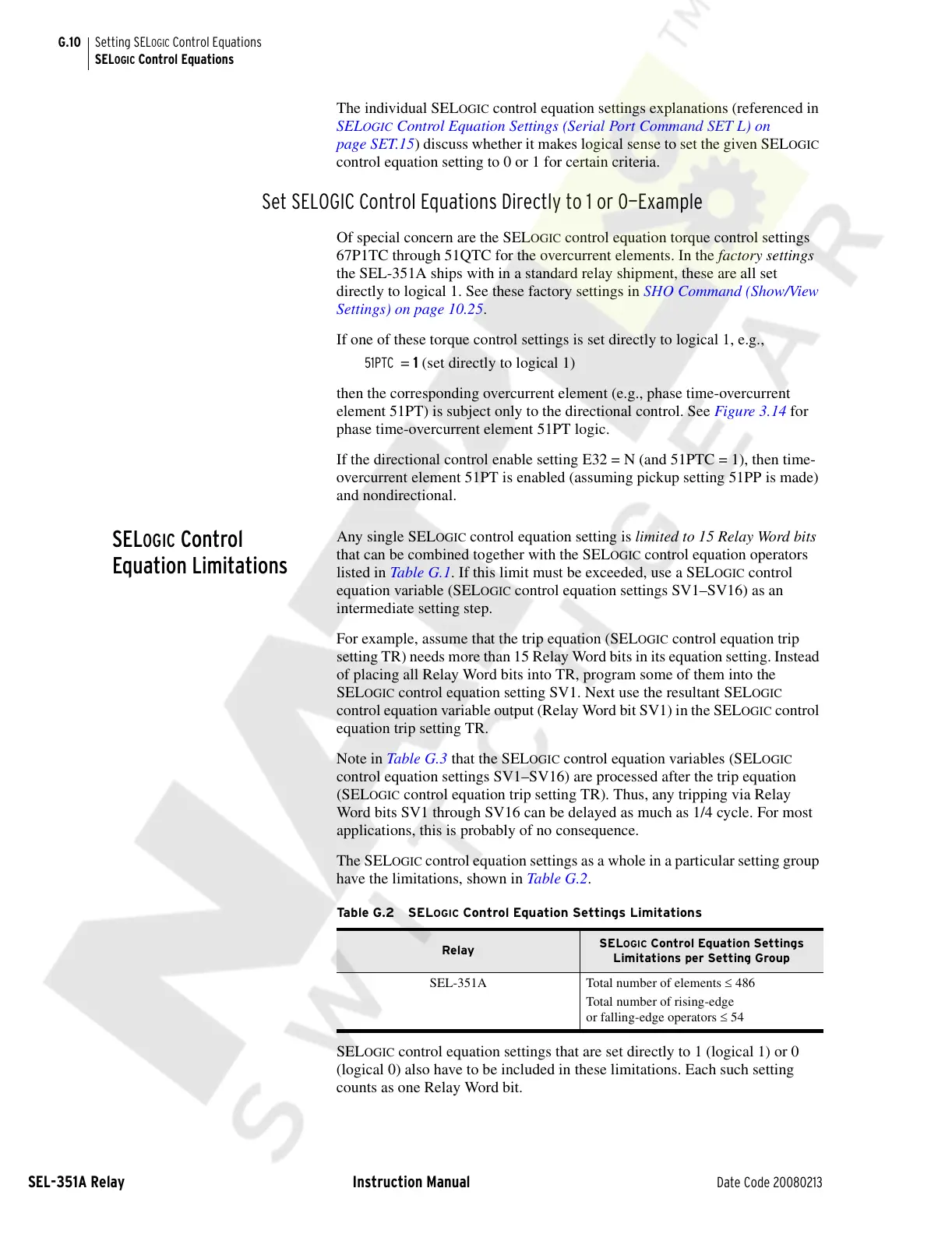

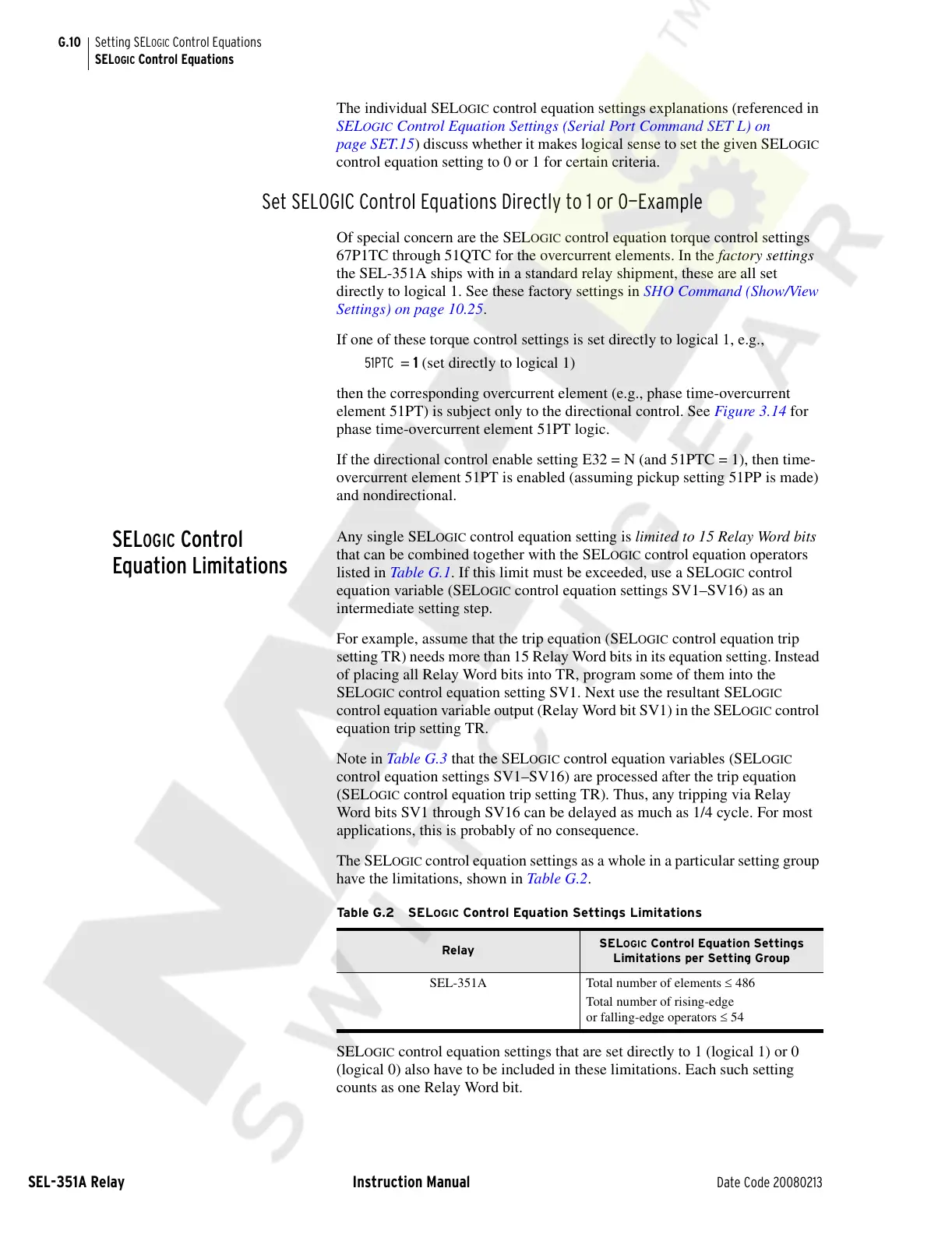

The SEL

OGIC control equation settings as a whole in a particular setting group

have the limitations, shown in Table G.2.

SEL

OGIC control equation settings that are set directly to 1 (logical 1) or 0

(logical 0) also have to be included in these limitations. Each such setting

counts as one Relay Word bit.

Ta b le G . 2 S E L OGIC Control Equation Settings Limitations

Relay

SELOGIC Control Equation Settings

Limitations per Setting Group

SEL-351A Total number of elements ≤ 486

Total number of rising-edge

or falling-edge operators ≤ 54

Courtesy of NationalSwitchgear.com

Loading...

Loading...