Section05FUELSYSTEM

Subsection 01 (CARBURETOR)

CAUTION: Heavy duty carburetor cleaner may

be harmful to the rubber parts, O-rings, etc.

Therefore, it is recommended to remove these

parts prior to cleaning.

INSPECTION

Inspect parts for corrosion damage (shaft, throttle

plate, spring, screw, check valve housing, etc.).

Inspect O-rings, diaphragms and gaskets.

Needle Valve

Inspect the tip of needle valve no. 3 for a grooved

condition. If worn, needle and seat must be re-

placed as a matched set.

Diaphragm

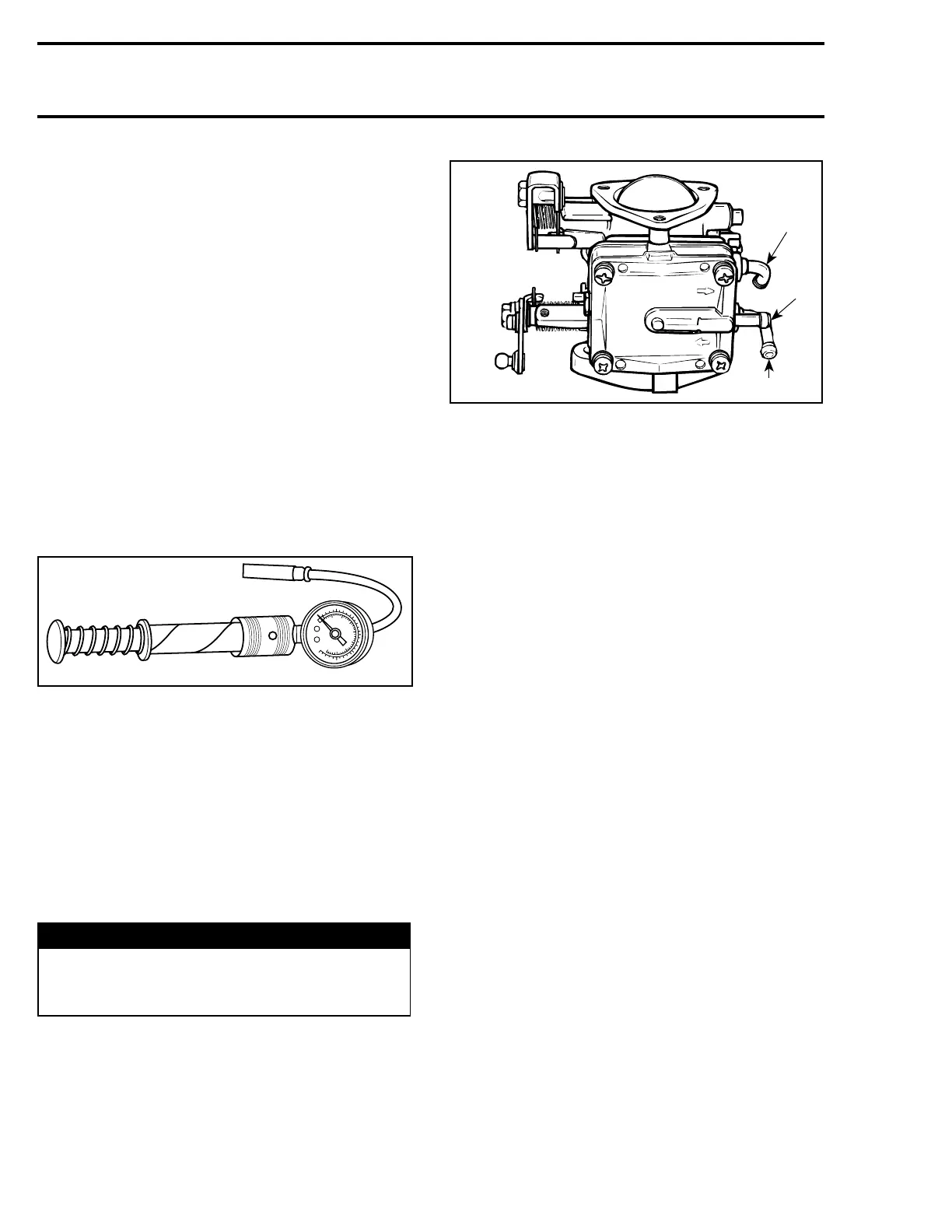

Using the pump gauge tester (P/N 295 000 114),

perform the following test proceeding as follows:

– Install pump gauge tester on pulse nipple.

35

4

3

25

2

15

1

5

60

50

40

30

20

10

295000114

– Pump tester until it reaches 28 kPa (4 PSI).

Diaphragm no. 4 must stand pressure for 10 sec-

onds. If pressure drops, replace diaphragm.

Fuel Pump Valve

Check fuel pump valve operation as follows:

Connect a clean plastic tubing to the inlet nipple

of the fuel pump body no. 5 and alternately apply

pressure and vacuum with the mouth. The inlet

valve should release with pressure and hold under

vacuum.

WARNING

Some fuel may be present in fuel pump. Be

careful not to swallow fuel when under vacu-

um.

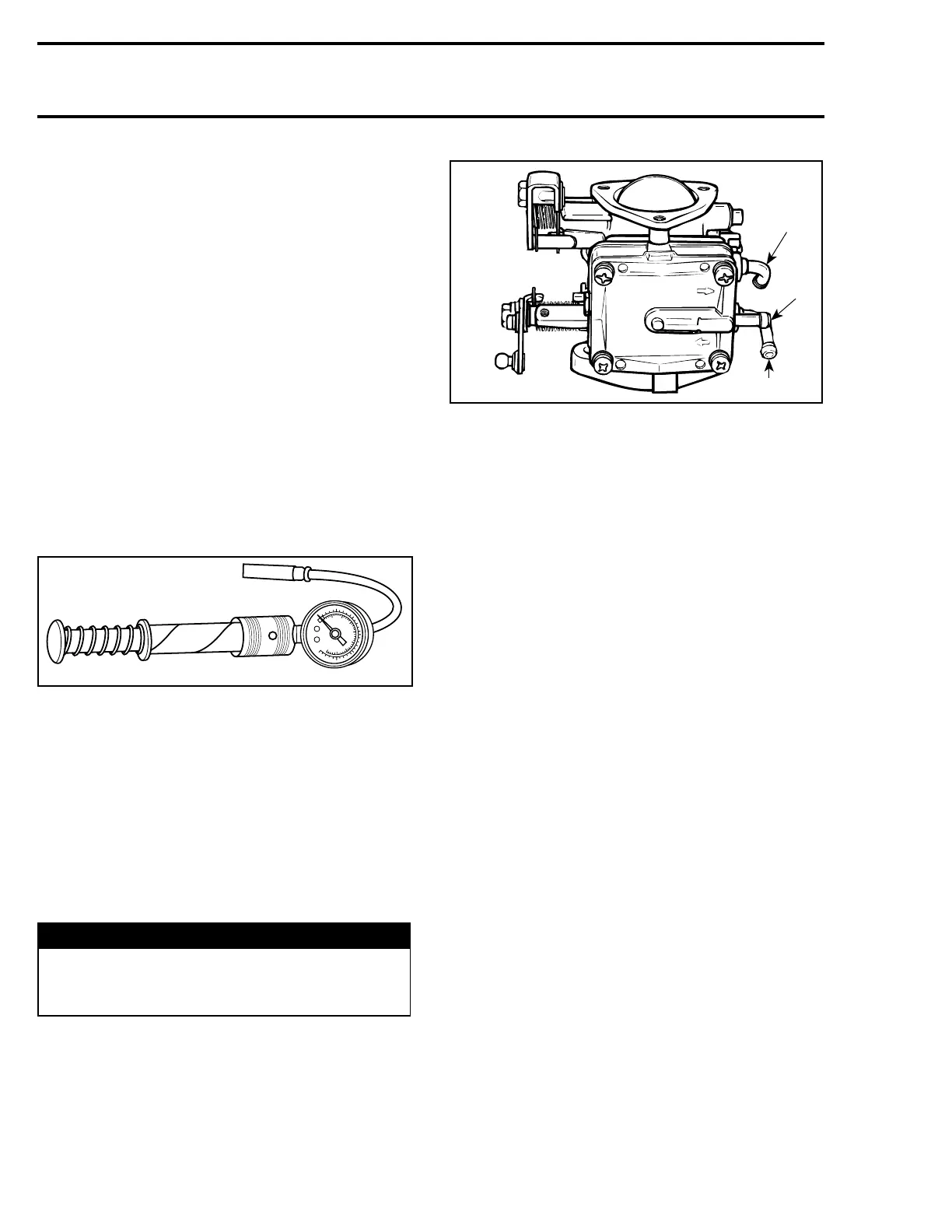

F01F0WA

1

2

3

TYPICAL

1. Fuel outlet nipple

2. Pulse nipple

3. Inlet nipple

Repeat the same procedure at the outlet nipple

of the fuel pump body. This time the outlet valve

should hold with pressure and release under vac-

uum.

Inspect valves. The pumping area should be free

of holes, tears or imperfections. Replace as need-

ed.

Internal Fuel Filter

To verify condition of filter no. 6, proceed as fol-

lows:

Remove pump cover no. 7, gasket no. 8,di-

aphragm no. 4 andthenpumpbodyno. 5 and

diaphragm no. 9.

Remove filter no. 6 from carburetor body then

clean filter and blow carefully with compressed air

(low pressure).

88 smr2005-052

Loading...

Loading...