Section05FUELSYSTEM

Subsection 01 (CARBURETOR)

For fuel system pressurization, refer to FUEL CIR-

CUIT.

ADJUSTMENTS

Carburetor Adjustment

There is no mixture adjustment to be performed

by the dealer.

IMPORTANT: Trying to bypass the anti-tamper

screws could damage the carburetor. It could

also change the engine emission level and lead

the engine not to meet the emission control reg-

ulations.

Throttle Cable Adjustment

NOTE: Do not activate throttle lever unnecessar-

ily. Carburetor is equipped with fuel accelerator

pump. This pump is injecting fuel into carburetors

each time throttle lever is depressed.

Lubricate cable with Bombardier Lube (P/N 293

600 016).

Throttle lever must reach handlebar grip without

causing strain to cable or carburetor cable bracket.

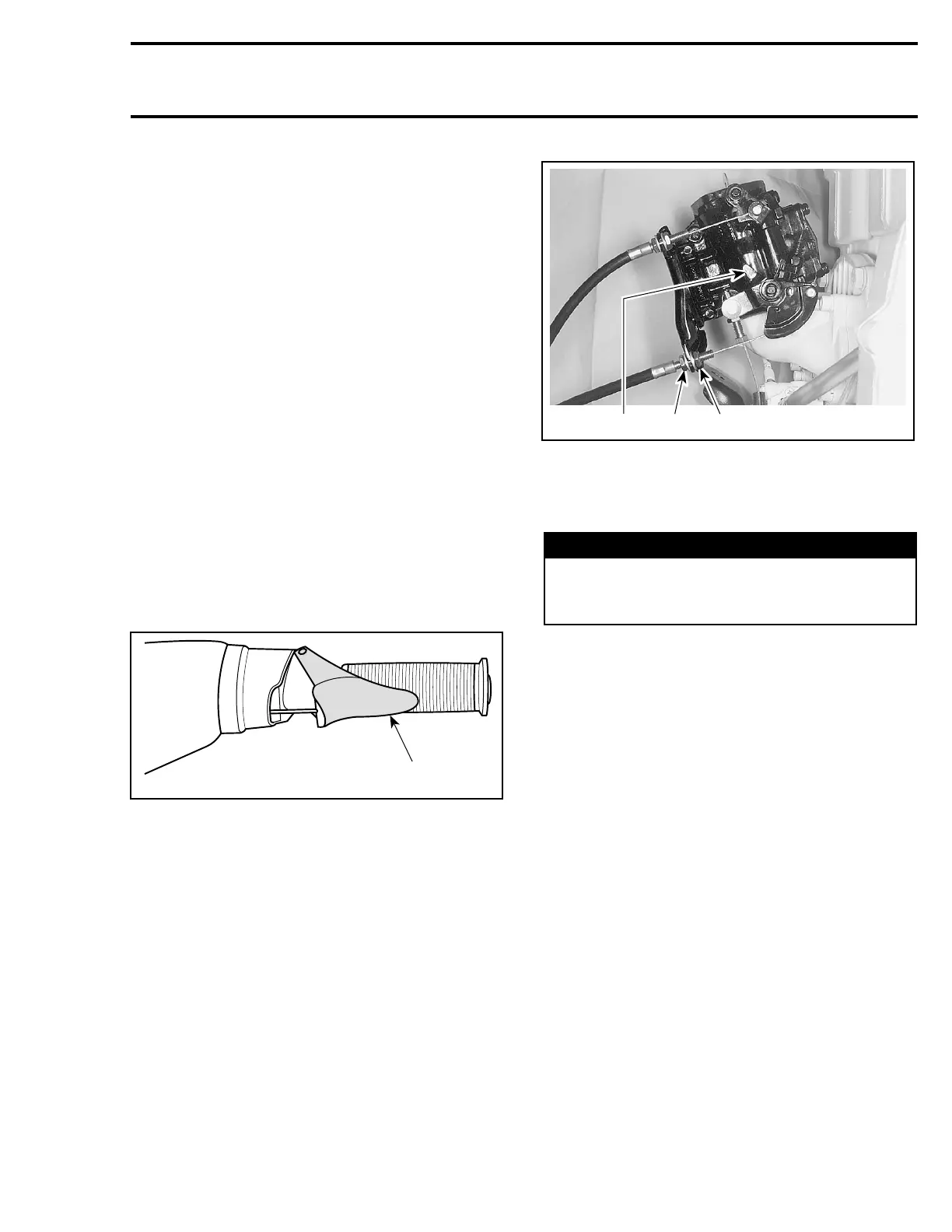

F01K08A

1

1. Must touch handlebar grip

Ensure carburetor throttle plate is fully open at

full throttle position. At this position, throttle lever

stopper is almost in contact (0.5 mm (1/64 in)) with

carburetor body.

NOTE: Apply a light pressure on the throttle plate,

a slight play should be obtained.

CAUTION: Improper cable adjustment will

cause strain on cable and/or damage cable

bracket or throttle lever at handlebar.

To adjust, loosen jam nut then turn adjustment nut

as necessary.

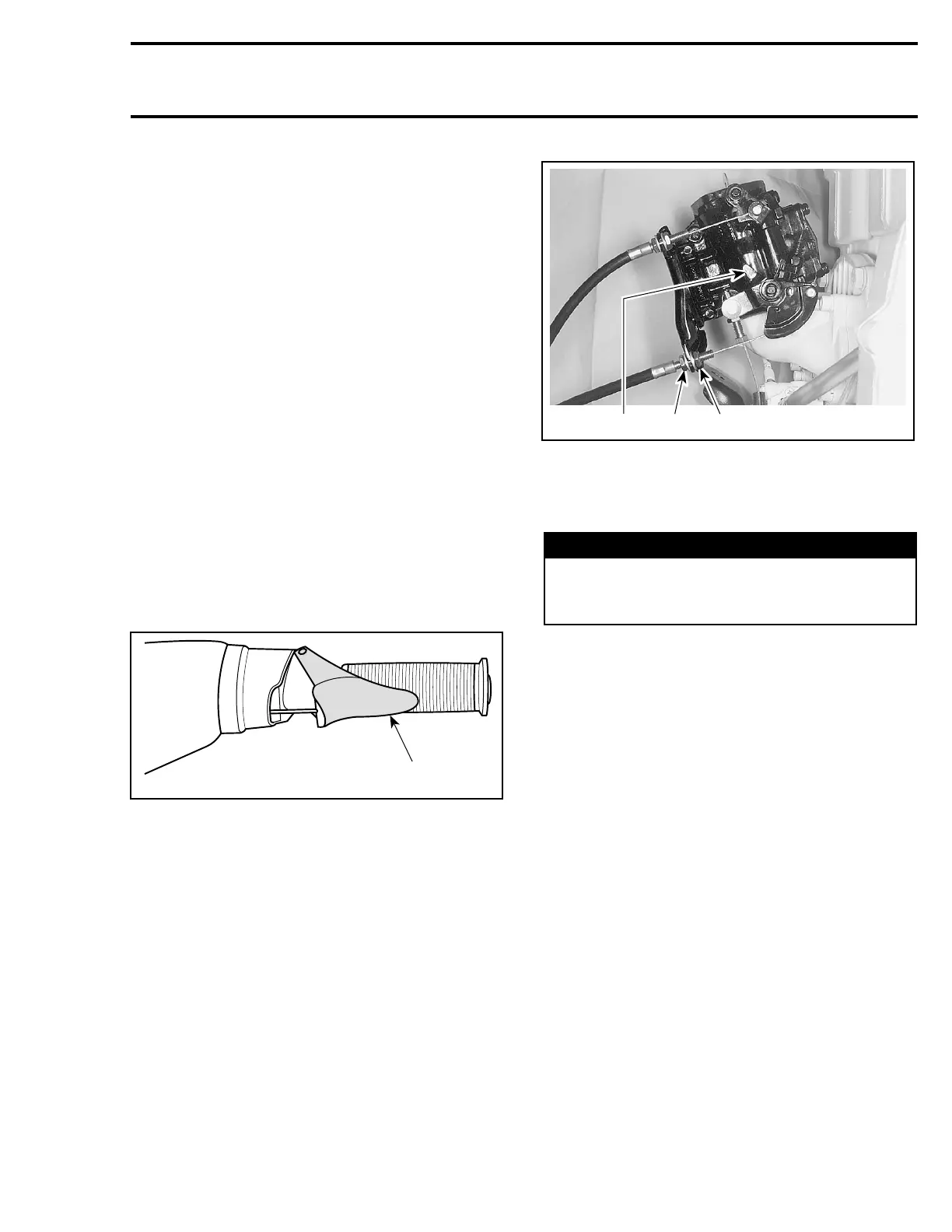

F01G0YC

1 23

1. Adjustment nut

2. Jam nut

3. Throttle lever stopper

Tighten jam nut and recheck adjustment.

WARNING

Make sure idle speed screw contacts stopper

when throttle lever is fully released at handle-

bar.

After throttle cable adjustment, always proceed

with the oil injection pump cable adjustment. Re-

fer to OIL INJECTION PUMP.

CAUTION: Improper oil injection pump syn-

chronization with carburetor can cause serious

engine damage.

Idle Speed Screw

Turning screw no. 20 clockwise increases engine

idle speed and turning screw counterclockwise

decreases engine idle speed.

smr2005-052 93

Loading...

Loading...