Section09PROPULSION

Subsection 01 (JET PUMP)

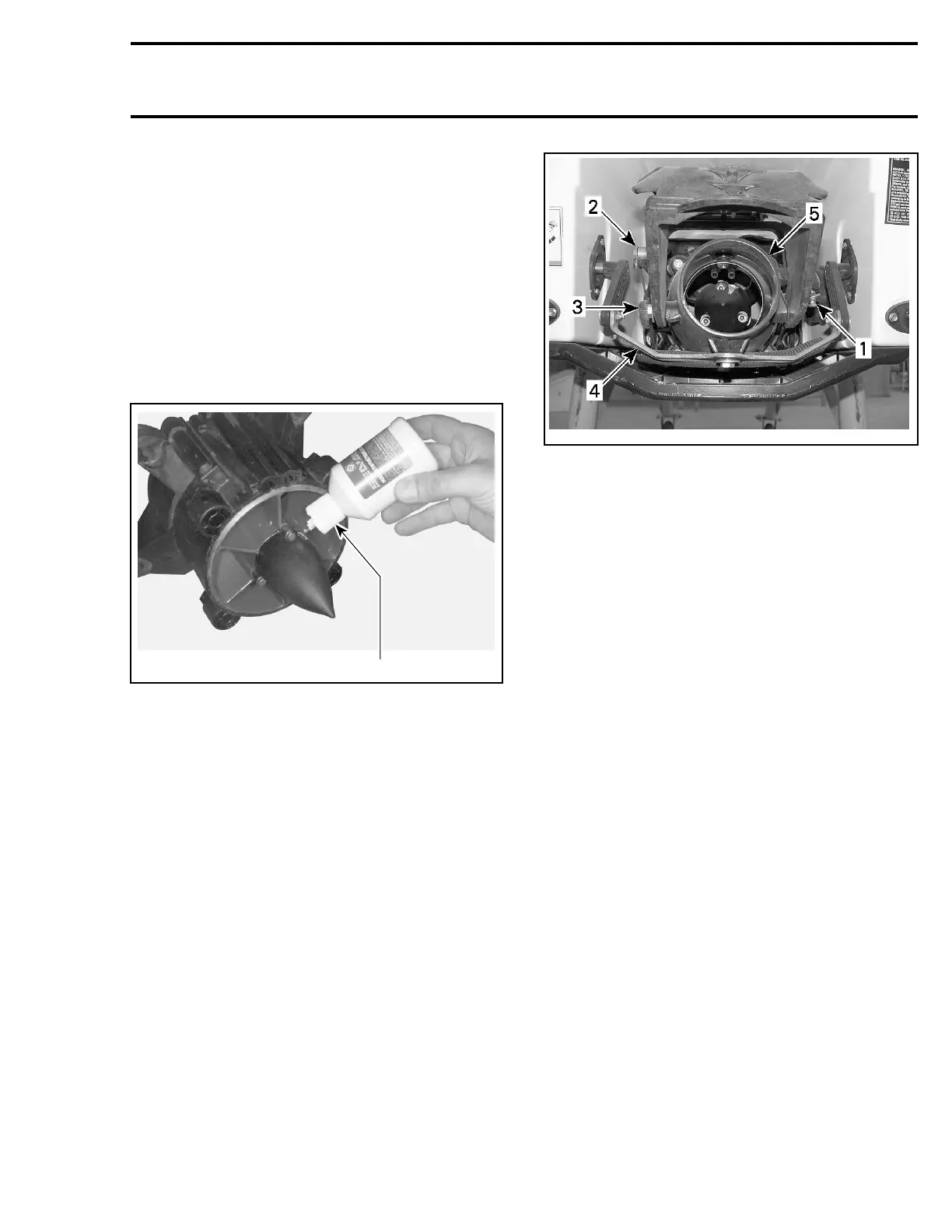

Place housing horizontally with a tilt angle of 15°

with the filler plug located on top. Remove filler

plug no. 5 from cover. Pour jet pump synthetic oil

(P/N 293 600 011) in reservoir until oil comes level

with bottom of hole. Let oil drain into housing and

after a few minutes add more oil until it is level

with bottom of filler hole.

CAUTION: This is a synthetic oil. Do not mix

with mineral based oil. Do not mix oil brands.

NOTE: When filling reservoir, oil must be poured

into cover quite slowly to allow complete housing

fill.

F00J0JA

1

TYPICAL

1. Pour oil slowly until it is level with bottom of filler hole

Apply Loctite 567 (pipe sealant) (P/N 293 800 013)

on filler plug threads and reinstall it on cover.

Properly reinstall removed parts.

REMOVAL

Venturi/Nozzle

GTI Series

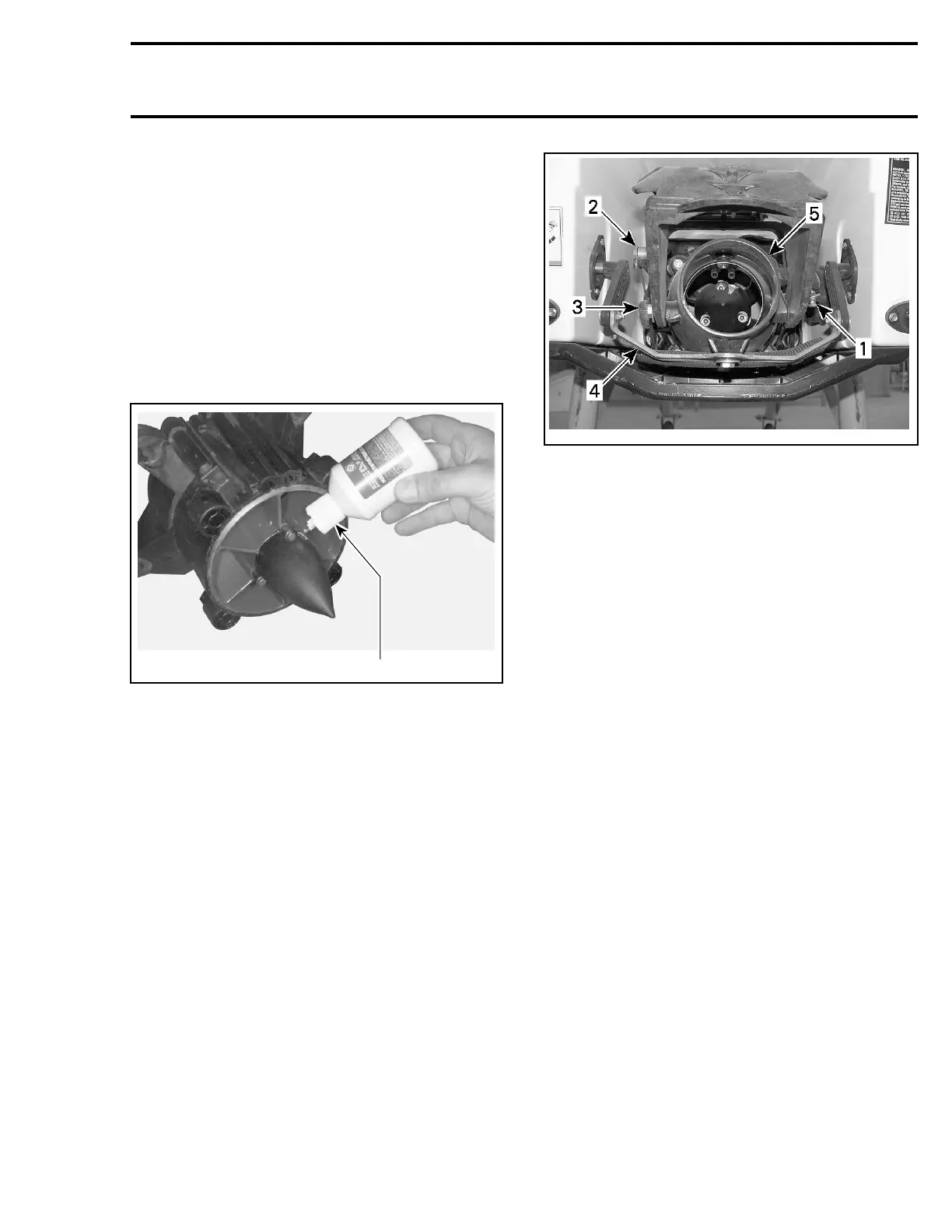

When the venturi is removed to check or replace

jet pump oil, the reverse gate removal is not nec-

essary. Remove steering and reverse cables, re-

verse spring and screw retaining “U” lever on noz-

zle.

smr2005-062-005_A

1. Steering cable

2. Reverse cable

3. Reverse spring

4. U lever

5. Nozzle

All Models

In all other situations, use the following procedure.

Remove reverse gate (GTI Series), refer to RE-

VERSE SYSTEM.

Remove retaining screws no. 10 and withdraw

venturi no. 4 with nozzle.

Jet Pump Housing

Remove venturi with nozzle.

Loosen 4 hexagonal bolts and remove flat wash-

ers from jet pump housing no. 11.

Removejetpumpwithawigglemovement.

NOTE: If jet pump can not be removed easily,

drive shaft may be sized in impeller. If so, remove

drive shaft with jet pump. Refer to DRIVE SYS-

TEM for drive shaft removal procedure.

DISASSEMBLY

NOTE: Whenever removing a part, visually check

for damage such as: corrosion, crack, split, break,

porosity, cavitation, deformation, distortion, heat-

ing discoloration, wear pattern, missing plating,

missing or broken needles in needle bearing, wa-

ter damage diagnosed by black-colored spots on

metal parts, etc. Renew any damaged part. As a

quick check, manually feel clearance and end play,

where applicable, to detect excessive wear.

smr2005-062 237

Loading...

Loading...