Section 04 LUBRICATION SYSTEM

Subsection 02 (OIL INJECTION PUMP)

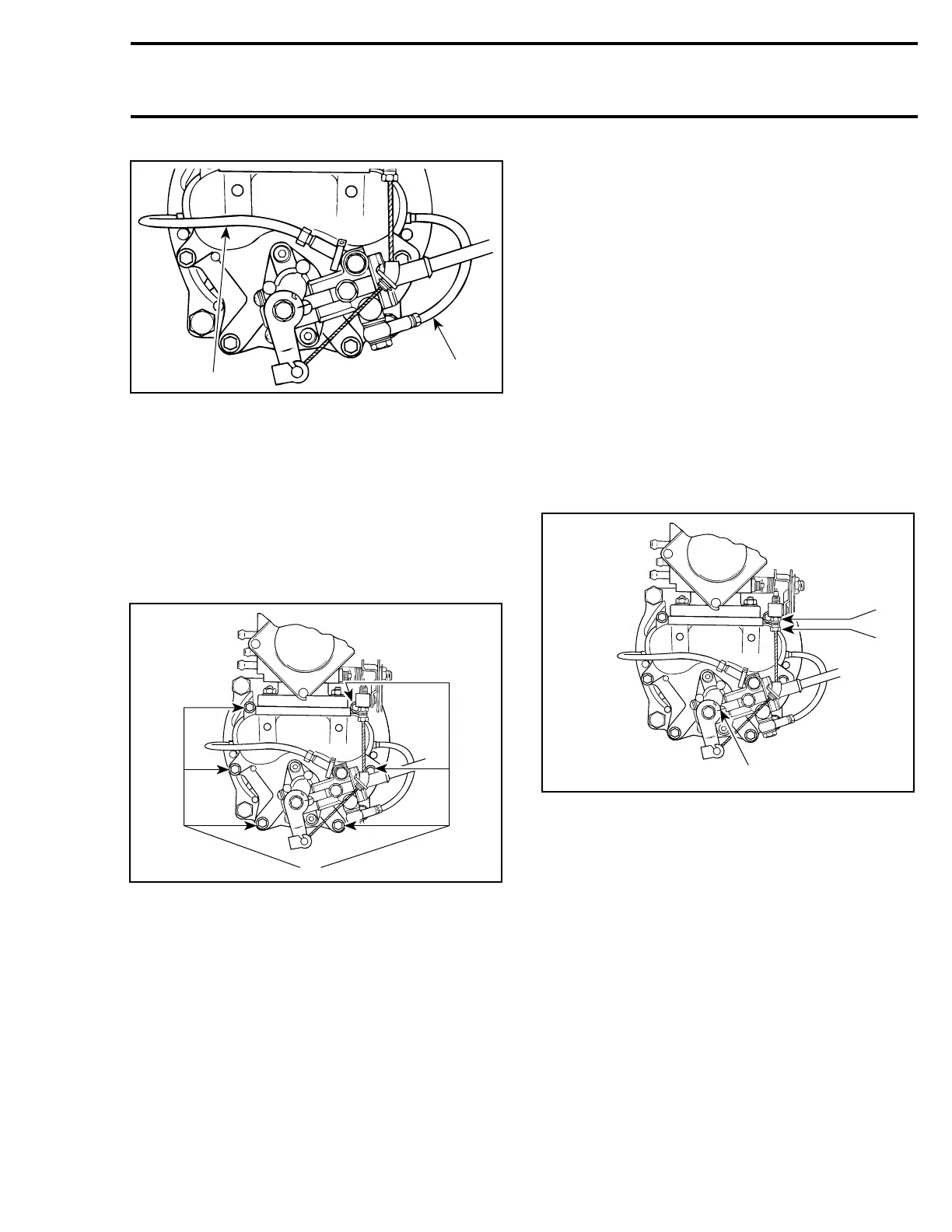

F01D4SA

1

1

TYPICAL

1. Small oil line

Oil Pump Gear

Install gear no. 3 to oil injection pump shaft.

Torque lock nut no. 4 to 4.5 N•m(40lbf•in).

NOTE: Make sure 1 washer is installed on each

side of gear.

Install intake manifold no. 2 to rotary valve cover

and torque screws no. 5 to 10 N•m(89lbf•in).

F01D4RC

A

TYPICAL

A. 10 N•m(89lbf•in)

787 RFI Engines

Oil Injection Pump and Shaft

Make sure shaft no. 8 is installed in crankshaft

end. Apply Loctite anti-seize lubricant (P/N 293

800 070) on the end of shaft.

Install pump. Secure with flat washers and

screws no. 6. Torque to 6 N•m(53lbf•in).

Install oil injection pump cable.

ADJUSTMENT

CAUTION: As oil injection pump adjustment

is dependent on throttle cable position, make

sure to perform throttle cable adjustment first

except if otherwise specified.

Preliminary Synchronization

NOTE: To check synchronization of pump as a

routine maintenance, see FINAL SYNCHRONIZA-

TION.

Adjust throttle cable. Refer to CARBURETOR

(717 engines) or ENGINE MANAGEMENT (787

RFI engines).

Turn oil pump cable adjustment nut to align refer-

ence marks on pump.

NOTE: A mirror may be used to facilitate this ver-

ification.

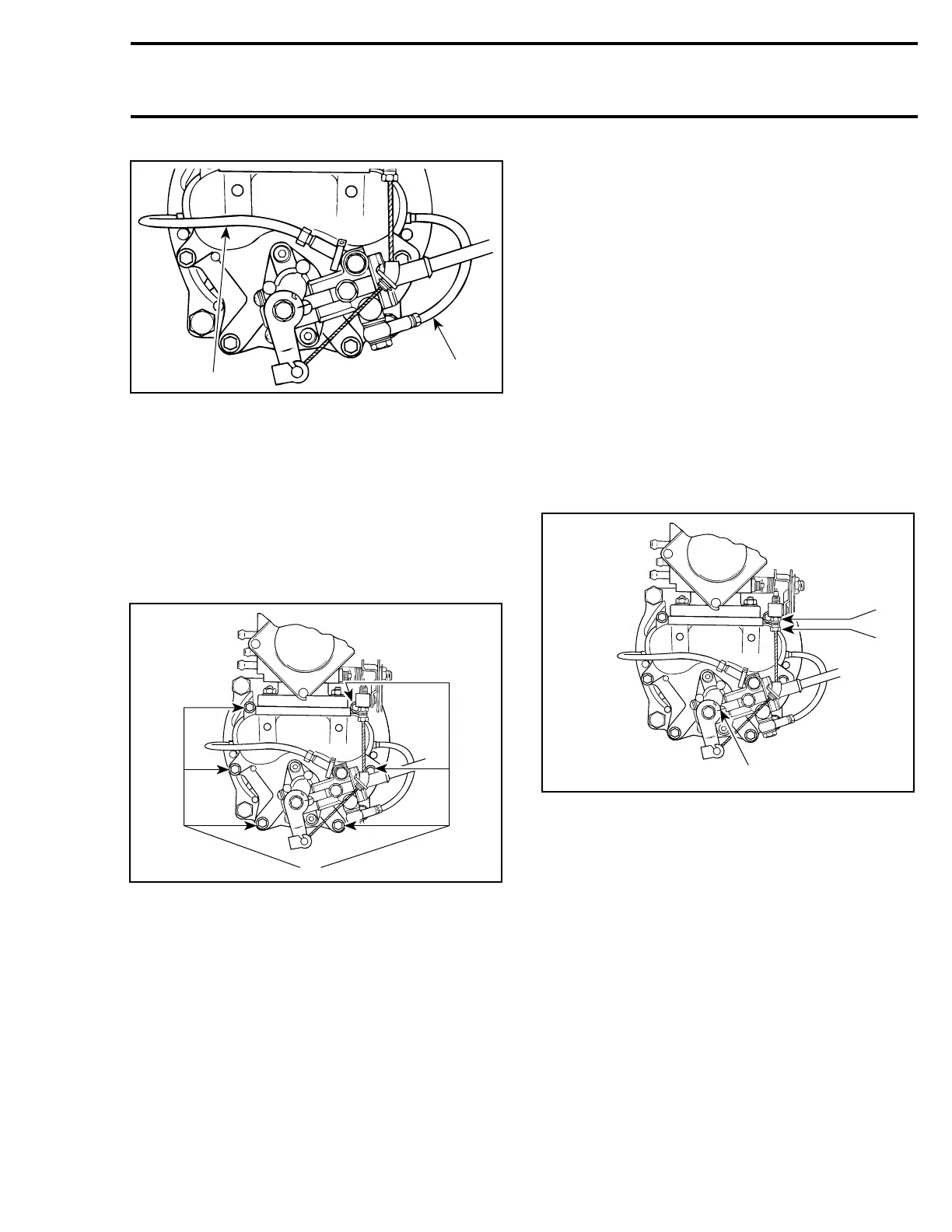

F01D4RE

2

3

1

TYPICAL — 717 ENGINES

1. Jam nut

2. Adjustment nut

3. Aligned marks

smr2005-051 81

Loading...

Loading...