Section09PROPULSION

Subsection 02 (DRIVE SYSTEM)

REMOVAL

PTO Flywheel Guard

Remove seats.

Remove seat support.

Remove plastic wing nuts no. 4 retaining PTO fly-

wheel guard no. 5 to engine support.

Detach PTO flywheel guard from engine and with-

draw from bilge.

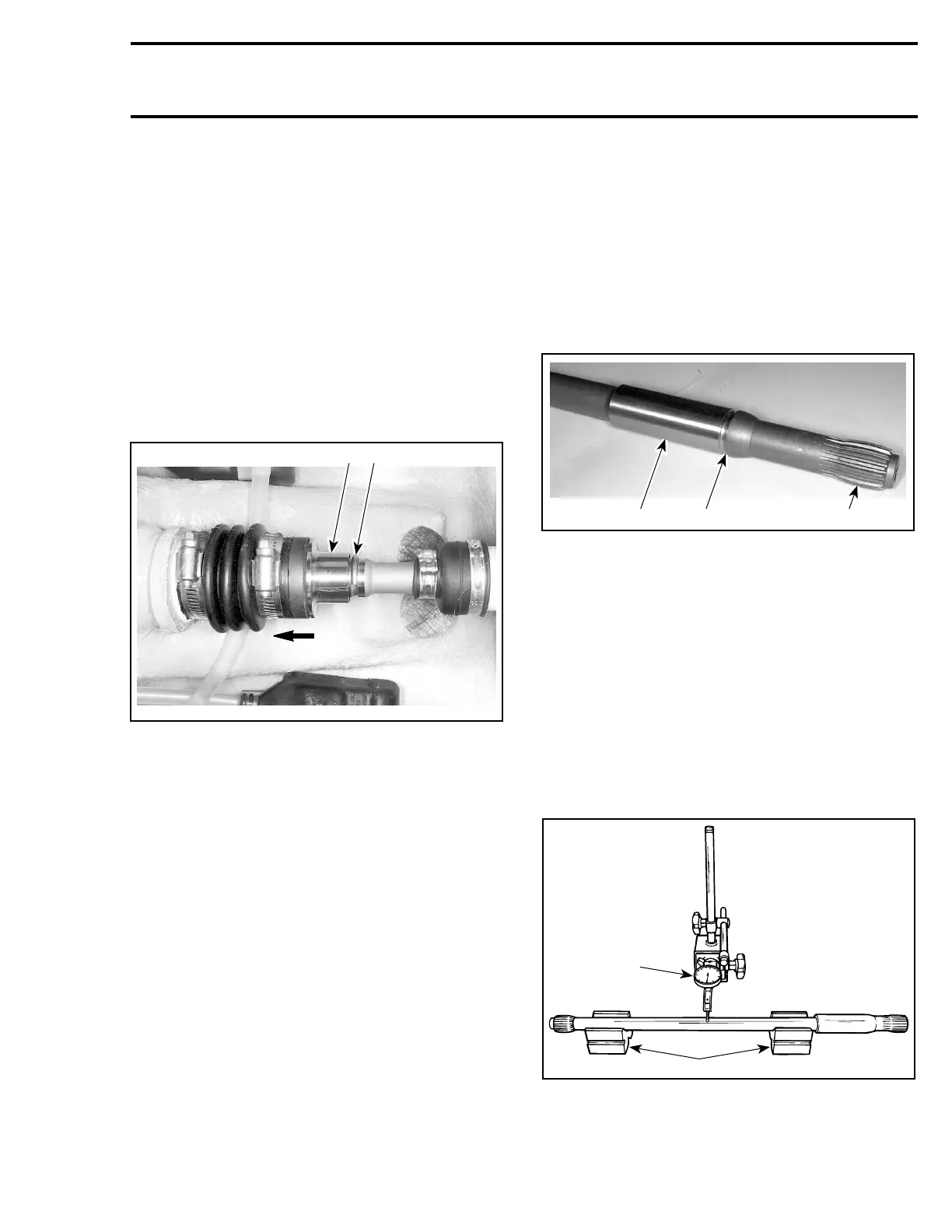

Circlip and Floating Ring

Hold floating ring no. 6 and compress boot no. 7;

then, pull out circlip no. 8 from drive shaft groove.

F06I06A

1 2

TYPICAL

1. Push floating ring

2. Remove circlip

Drive Shaft

Pull out drive shaft no. 9.

NOTE: If the drive shaft is jammed into PTO fly-

wheel, it may be necessary to remove PTO fly-

wheel from engine to then remove drive shaft.

Boot

Loosen gear clamp no. 10 holding boot no. 7,then

carefully pull boot and carbon ring no. 11 from hull

insert.

Carbon Ring

Loosen gear clamp no. 12 then pull carbon ring

no. 11 from boot no. 7.

INSPECTION

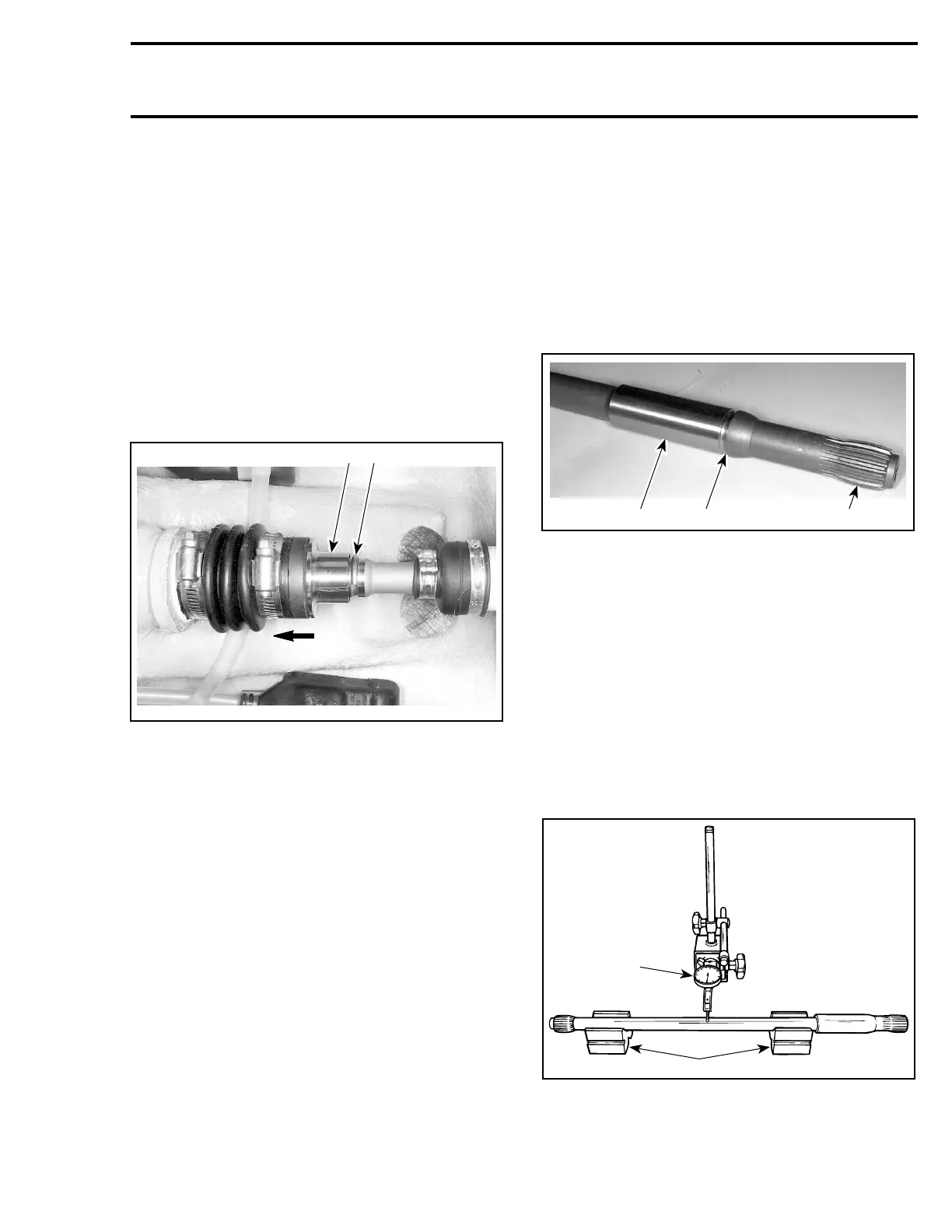

Drive Shaft

Inspect condition of drive shaft and PTO flywheel

splines.

Inspect condition of groove.

With your finger nail, feel machined surface of

drive shaft. If any irregular surface is found, re-

new drive shaft.

F01I0FA

321

1. Surface condition

2. Groove condition

3. Splines condition

Excessive deflection could cause vibration and

damage to drive shaft splines, impeller, flywheel

or floating ring (seal carrier depending upon the

model).

Place drive shaft on V-blocks and set-up a dial

gauge in center of shaft. Slowly rotate shaft; dif-

ference between highest and lowest dial gauge

reading is deflection. Refer to the following illus-

tration.

Maximum permissible deflection is 0.5 mm

(.020 in).

1

2

F01J15A

MEASURING DRIVE SHAFT DEFLECTION

1. Dial gauge

2. V-blocks

smr2005-063 255

Loading...

Loading...