Section07ELECTRICALSYSTEM

Subsection 01 (IGNITION SYSTEM)

Repeat armature plate positioning procedure if

timing mark position is not adequate.

TESTING PROCEDURES

When dealing with ignition problems, the follow-

ing items should be verified in this order:

1. Spark occurrence/spark plug condition.

2. Electrical connections.

3. Magneto output.

4. Multi-Purpose Electronic Module (MPEM).

5. Ignition coil output.

CAUTION: Whenever replacing a component in

ignition system, check ignition timing.

NOTE: To perform verifications, a good quality

multimeter such as Fluke 111 (P/N 529 035 868)

should be used.

529 035 868

SPARK PLUGS

Refer to TESTING PROCEDURES of the 787 RFI

engine further in this section.

GENERATING COIL

Static Test

Disconnect magneto wiring harness connector.

Install the 4-pin magneto harness adapter (P/N 295

000 131).

F01B28A

TYPICAL

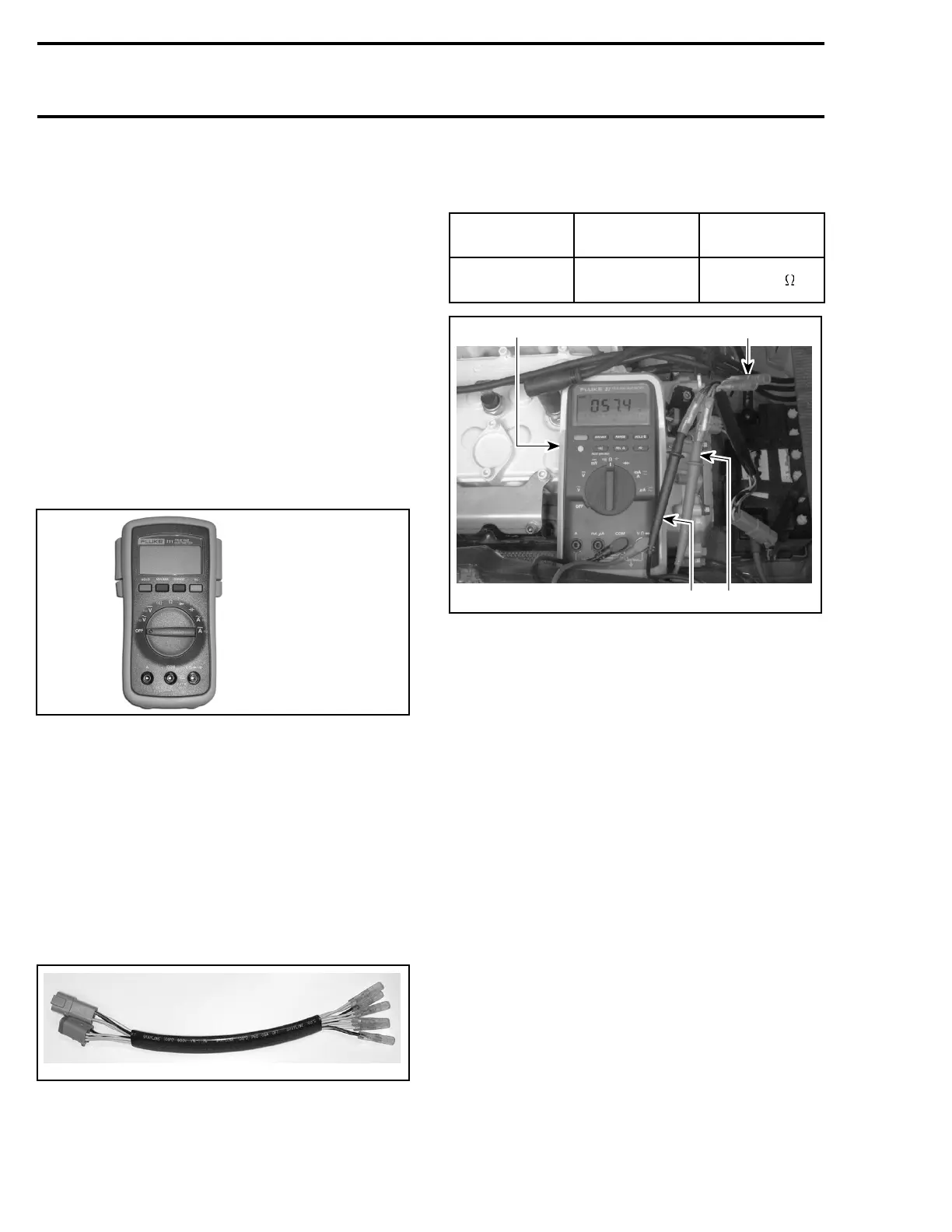

Check resistance with a multimeter. Refer to the

following table for values and wire colors.

PART NAME

ADAPTER

WIRE

RESISTANCE

Generating coil

BLACK with

RED/BLACK

40 - 76

F01H5WA

21

3

4

1. Multimeter

2. 4-pin magneto harness adapter

3. RED/BLACK wire

4. BLACK wire

Dynamic Test

1. Connect spark plug cables to grounding de-

vice.

2. Disconnect magneto wiring harness connec-

tor.

3. Install the 4-pin magneto harness adapter

(P/N 295 000 131).

4. Connect positive test probe of the multimeter

to the RED/BLACK wire of the 4-pin magneto

harness adapter.

5. Connect negative test probe of the multimeter

to BLACK wire of the 4-pin magneto harness

adapter.

6. Set multimeter to Vac scale.

7. Crank engine and note result. The obtained

valueshouldbebetween18and25Vac.

8. If the generating coil is out of specification,

replace it.

150 smr2005-057

Loading...

Loading...