Section05FUELSYSTEM

Subsection 01 (CARBURETOR)

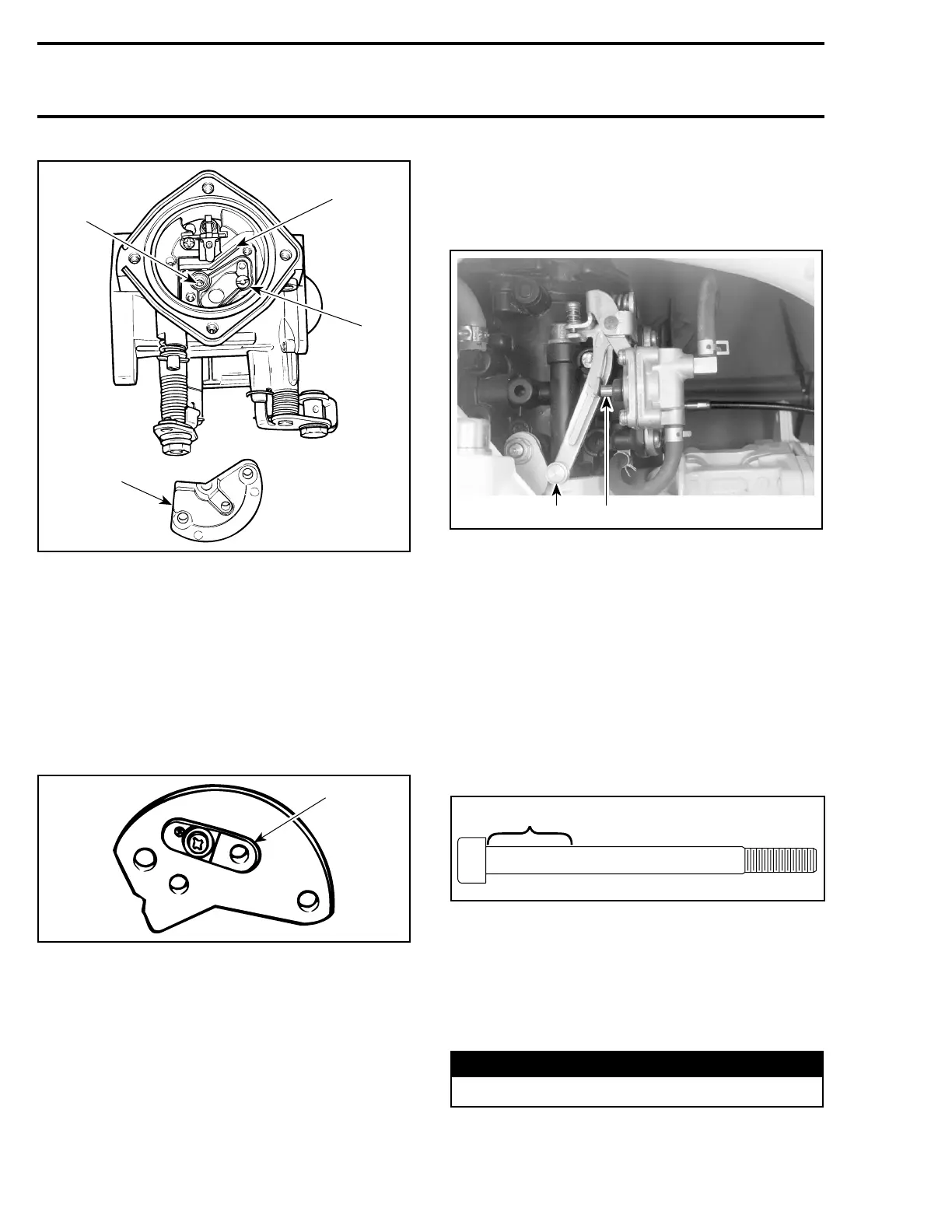

1

F01F11A

2

3

4

TYPICAL

1. Pilot jet

2. Gasket

3. Main jet

4. Check valve housing removed

Check Valve Assembly

The check valve is needed if a back pressure oc-

curs into carburetor. It will prevent fuel from flow-

ing back into carburetor lower portion.

Inspect check valve no. 17. Itshouldbefreeof

holes, tears or imperfections. Replace as needed.

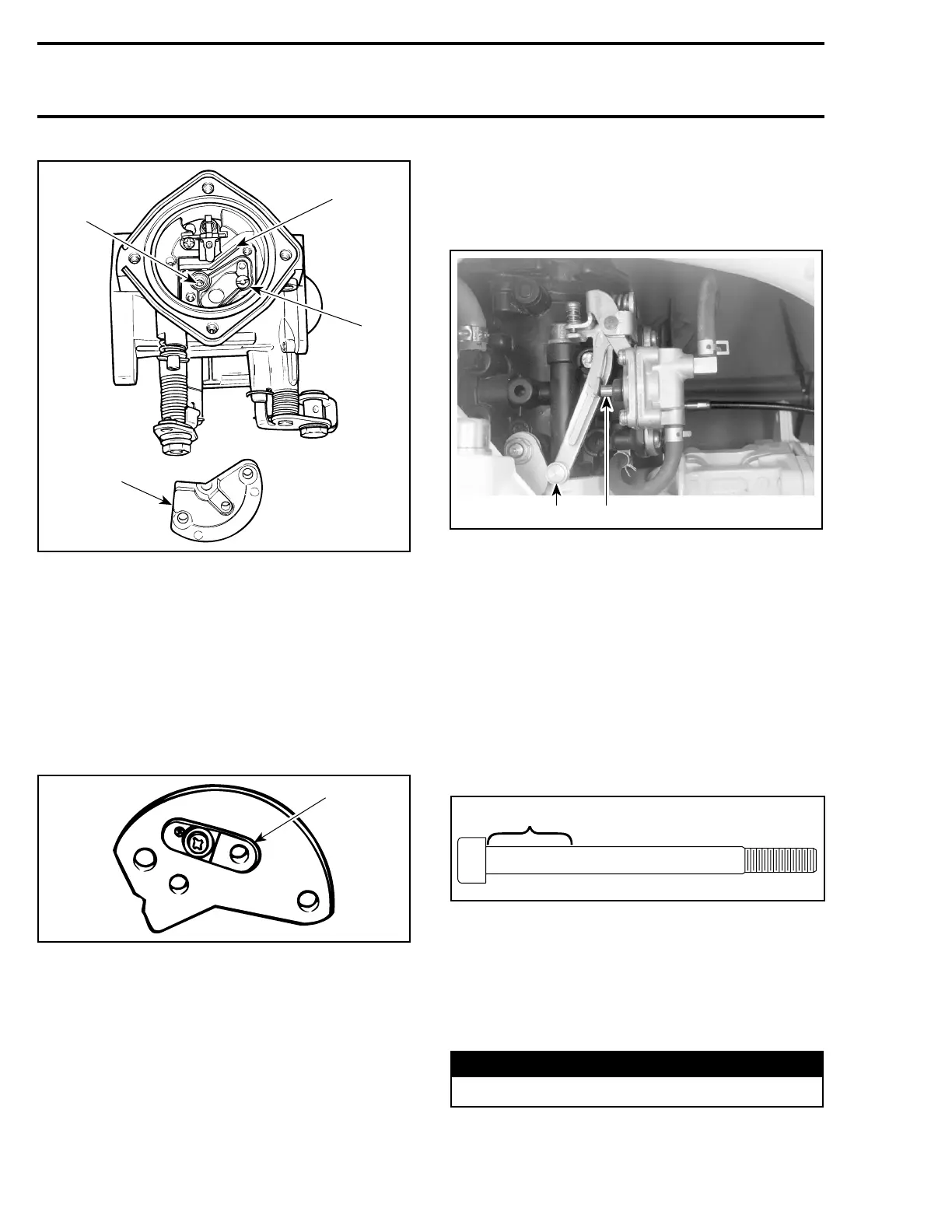

F01F12A

1

1. Check valve

NOTE: Prior to check valve assembly installation,

remember to set gasket no. 18.

Diaphragm and Cover

Install diaphragm no. 10 with its integrated O-ring

into carburetor groove. Make sure that the tab of

cover no. 19 is inserted into carburetor notch.

Fuel Accelerator Pump

Lubricate pump plunger, roller and cam with syn-

thetic grease (P/N 293 550 010) and roller shaft

with Bombardier Lube (P/N 293 600 016).

F06F06B

12

TYPICAL

1. Apply synthetic grease to plunger

2. Apply Bombardier Lube on roller shaft

INSTALLATION

Carburetor

At installation, pay attention to the following:

Install carburetor with gasket to intake manifold

(rotary valve cover).

Apply synthetic grease (P/N 293 550 010) on

screws no. 1. Then, install screws with lock

washers no. 2 andtorqueto20N•m(15lbf•ft).

1

smr2005-052-002_a

1. Apply synthetic grease here

Fuel Lines and Hose Clamps

If fuel line ends are damaged, cut damaged end

before reinstallation.

Properly install clamps.

WARNING

Make sure there is no leak in fuel system.

92 smr2005-052

Loading...

Loading...