Section 07 ELECTRICAL SYSTEM

Subsection 03 (STARTING SYSTEM)

F01H0UA

2

1

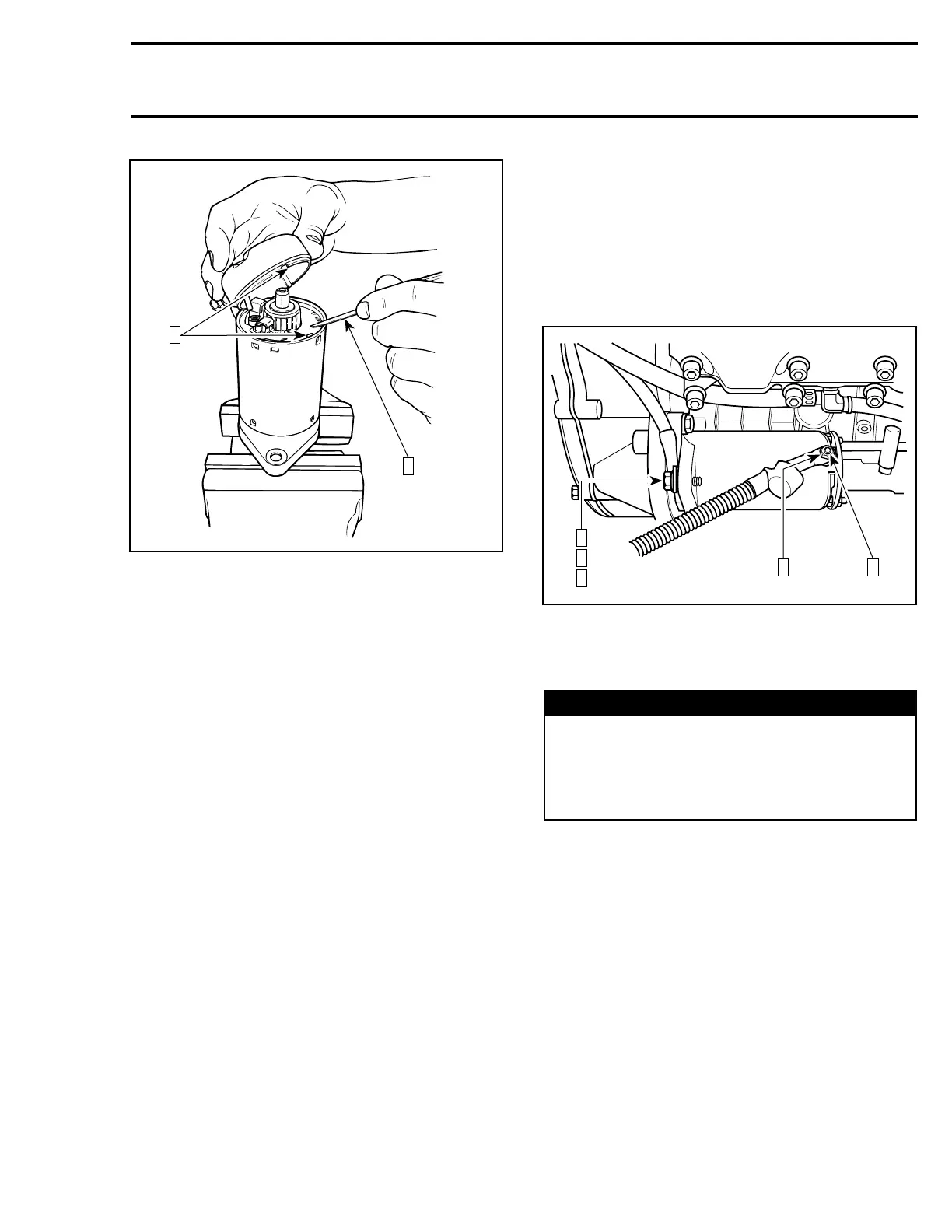

Step 1: Retaining brush holder with a screwdriver

Step 2: Align here

Align end frame notch with brush holder

notch/yoke protrusion.

CAUTION: Make sure end frame fits perfectly

on yoke.

INSTALLATION

Starter

Installation is essentially the reverse of removal

procedure. However, pay particular attention to

the following.

Make sure that starter and engine mating surfaces

are free of debris. Serious trouble may arise if

starter is not properly aligned.

Starter Retaining Screws

Apply service products as per the exploded view

given at the beginning of the section, on threads

and torque starter screws no. 13 and no. 16 to

22 N•m(16lbf•ft).

RED Positive Cable Retaining Nut

Connect the RED positive cable to the starter and

torque nut no. 17 to 6 N•m(53lbf•in). Apply

dielectric grease (P/N 293 550 004) on terminal

and nut.

BLACK Negative Cable Retaining Screw

and Teeth Washer

Apply Loctite 271 (P/N 293 800 005) to screw.

Connect BLACK negative cable to starter using

flat washer, teeth washer no. 15 and screw

no. 14. Torque screw to 22 N•m(16lbf•ft). Ap-

ply dielectric grease (P/N 293 550 004) on terminal

and screw.

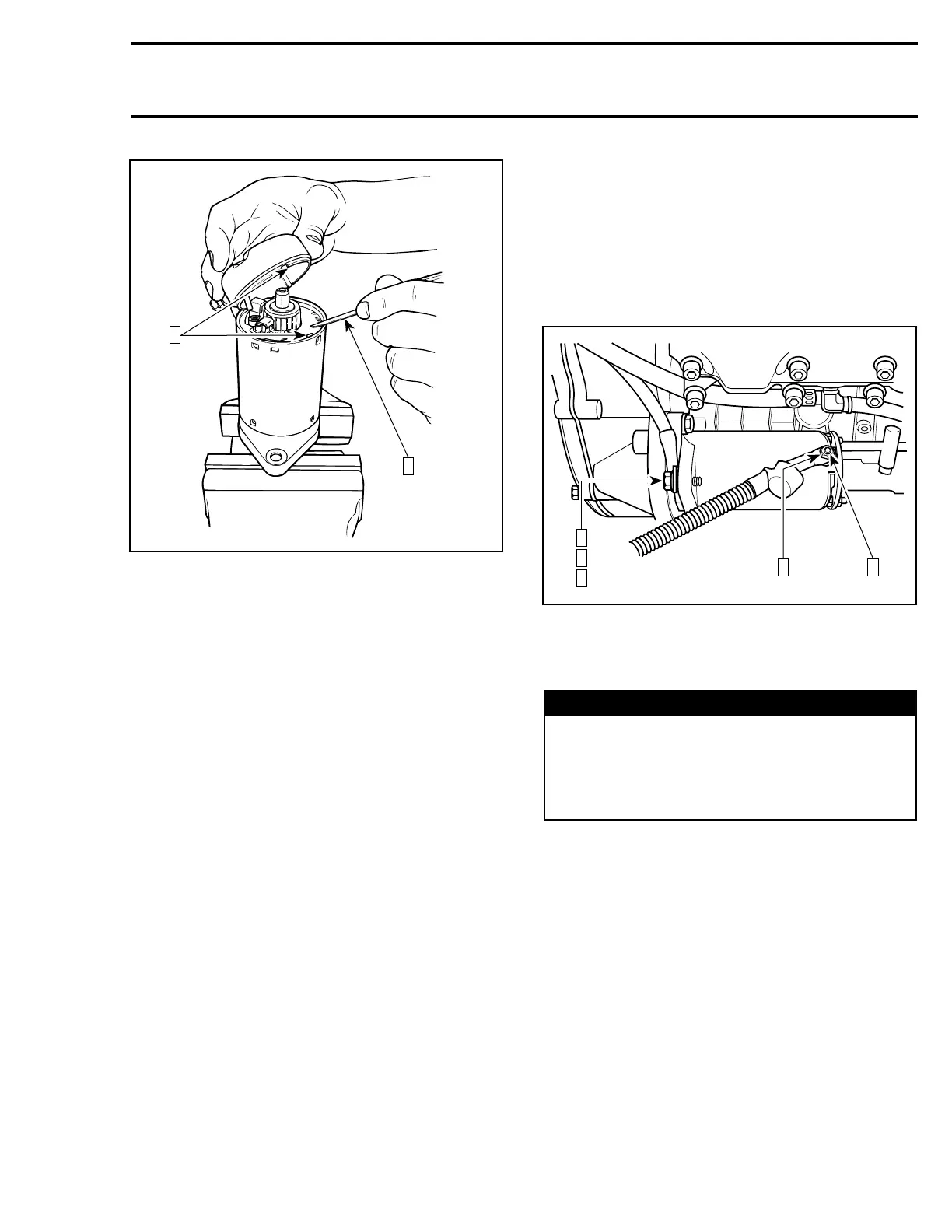

F01H1JC

1 4

2

3

4

717 ENGINE SHOWN

Step 1: Torque nut to 6 N•m(53lbf•in)

Step 2: Apply Loctite 271 on screw

Step 3: Torque screw to 22 N•m(16lbf•ft)

Step 4: Apply dielectric grease

WARNING

Always connect RED positive cable first then

BLACK negative cable last. Whenever con-

necting the RED positive cable to the starter

motor make sure the battery cables are dis-

connected to prevent electric shock.

smr2005-059 193

Loading...

Loading...