Section 06 ENGINE MANAGEMENT (RFI)

Subsection 03 (COMPONENT ADJUSTMENT, INSPECTION AND REPLACEMENT)

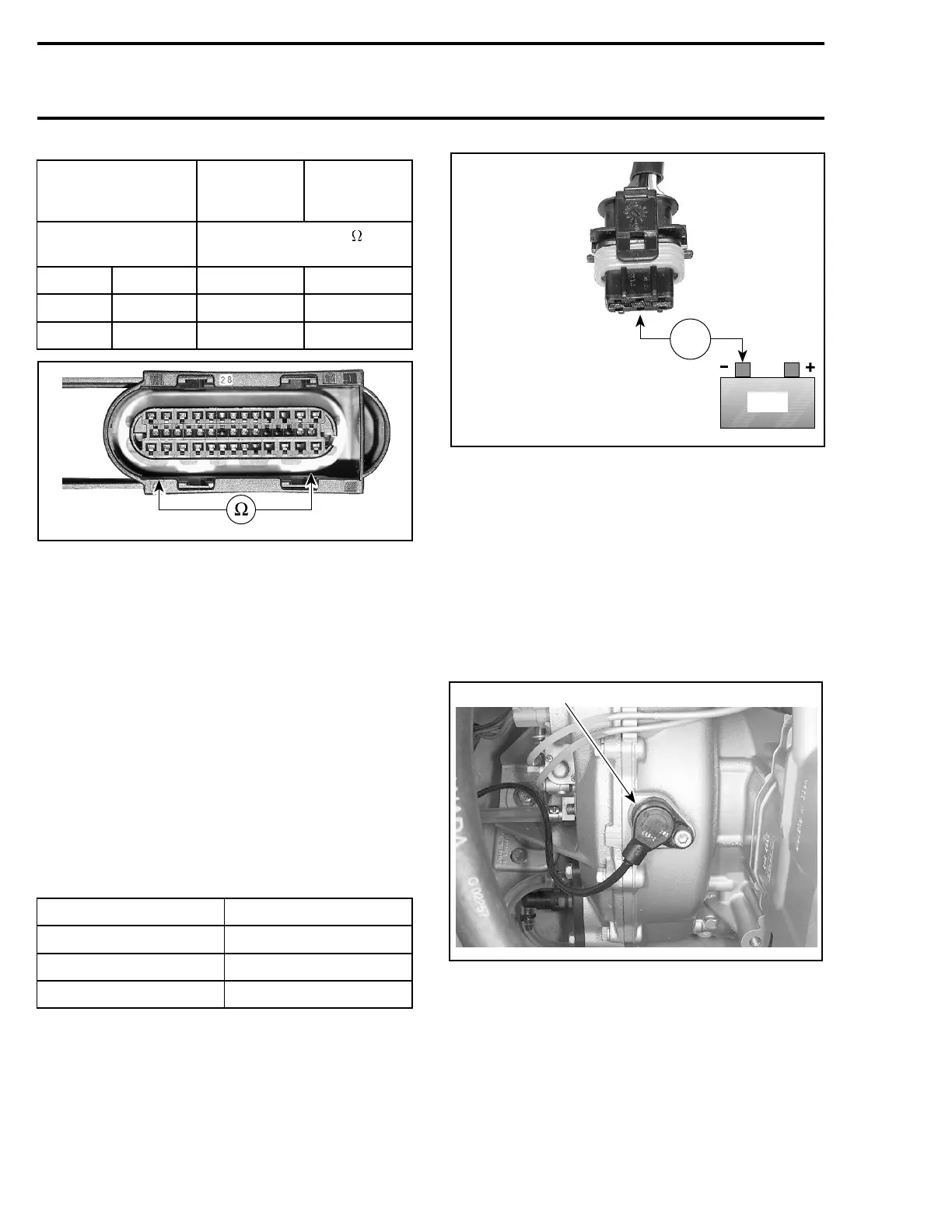

ECM CONNECTOR

THROTTLE

IDLE

POSITION

WIDE OPEN

THROTTLE

POSITION

PIN

RESISTANCE

@20°C(68°F)

A-24 A-25 2600 - 2700 710 - 1300

A-25 A-39 1600 - 2400 1600 - 2400

A-24 A-39 710 - 1300 2600 - 2700

smr2005-056-015_a

NOTE: The resistance value should change pro-

portionally to throttle movement. Otherwise, re-

place TPS.

If resistance values are correct, perform the VOLT-

AGE TEST below.

If resistance values are incorrect, check wiring har-

ness. If wiring is faulty, repair/replace. If wiring is

good, replace TPS.

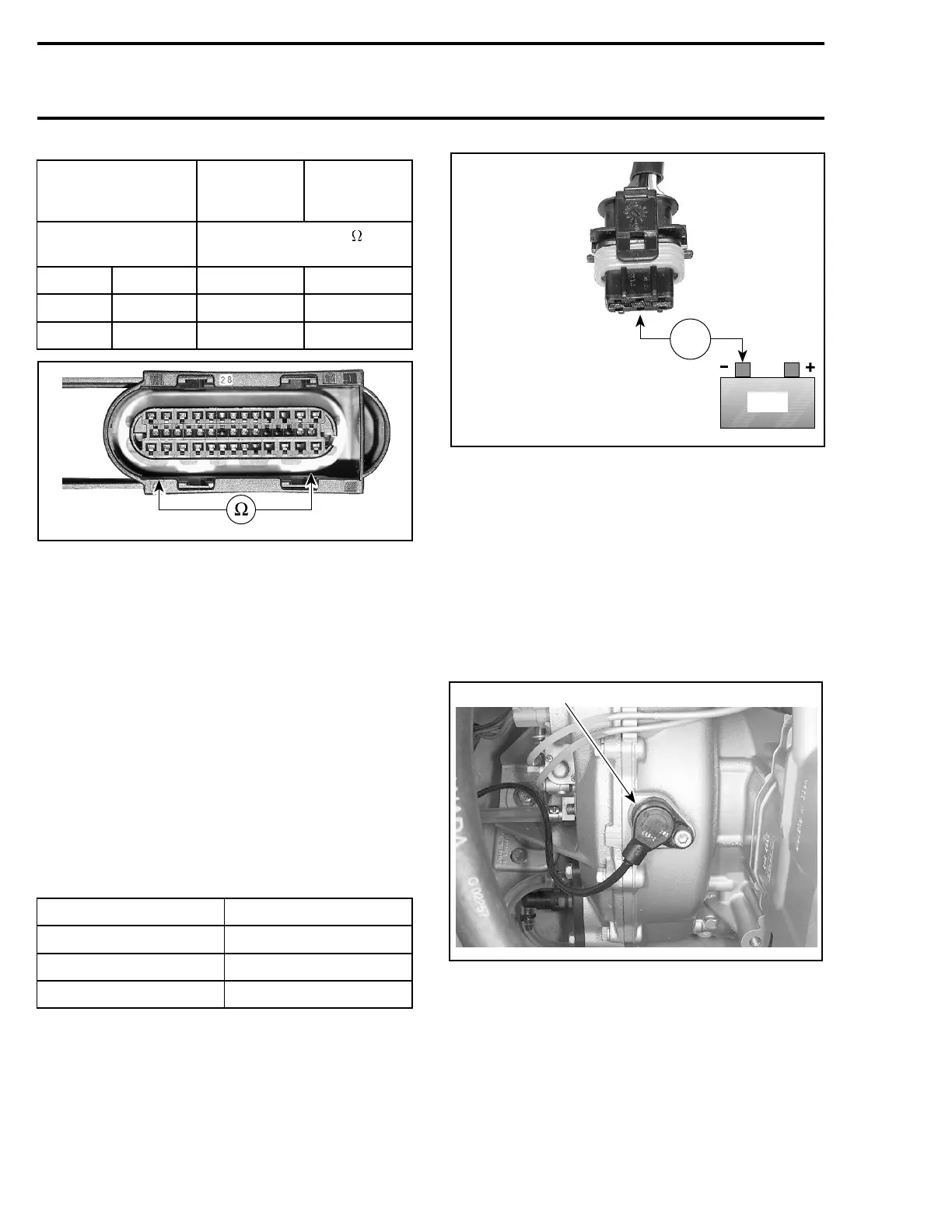

Voltage Test

Check the ECM voltage output to the TPS.

Disconnect connector from TPS.

Remove and reinstall the safety lanyard to activate

the ECM.

Check the voltage readings from harness connec-

tor as follows.

TPS CONNECTOR VOLTAGE

Pin 1 with battery ground 0V

Pin 2 with battery ground 5V

Pin 3 with battery ground 4.5 - 5 V

BAT

Vdc

smr2005-056-016_a

If voltage test is not good, try a new ECM.

If voltage test is good, everything is in order.

THROTTLE BODY

Check that the throttle plate moves freely and

smoothly when depressing throttle lever. Verify

if throttle body is free of corrosion.

CRANKSHAFT POSITION

SENSOR (CPS)

F07H0CA

1

1. Crankshaft position sensor (CPS)

Resistance Test

Disconnect the A connector from the ECM.

Using a multimeter, check the resistance on the

ECM connector as per table.

136 smr2005-056

Loading...

Loading...